Fiber directionality testing device

A testing device and fiber orientation technology, applied in the field of fibers, can solve the problems of testing methods and devices without fiber arrangement state, and achieve the effects of accurate and reliable test results and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

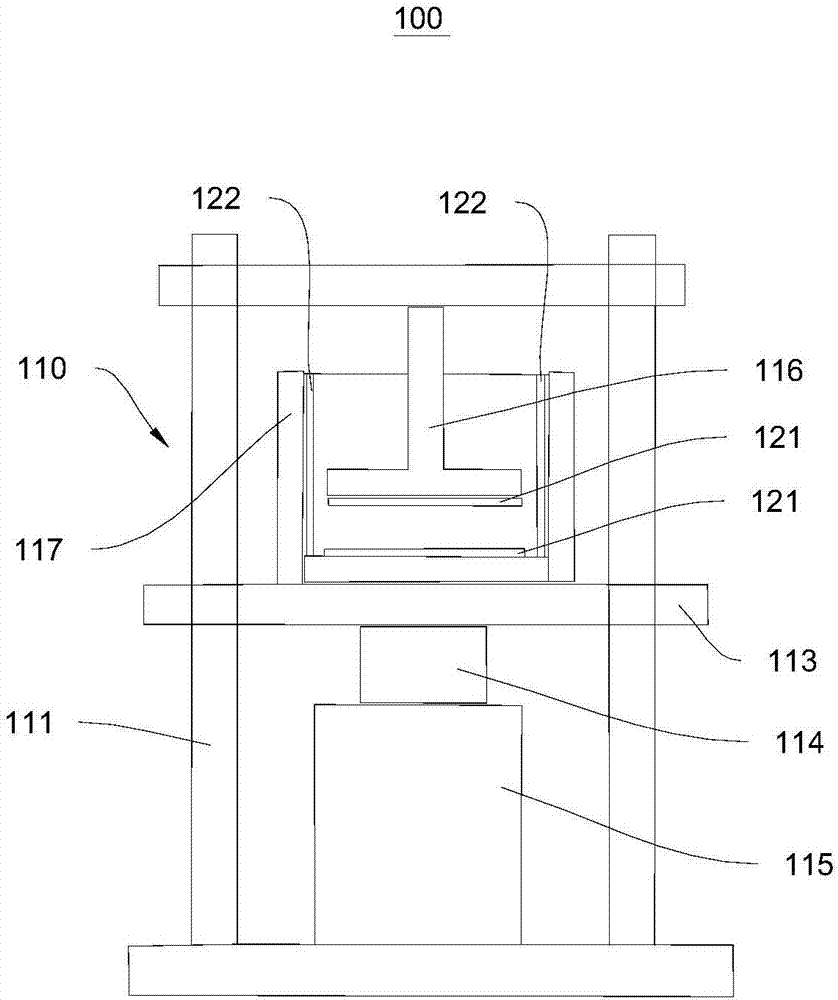

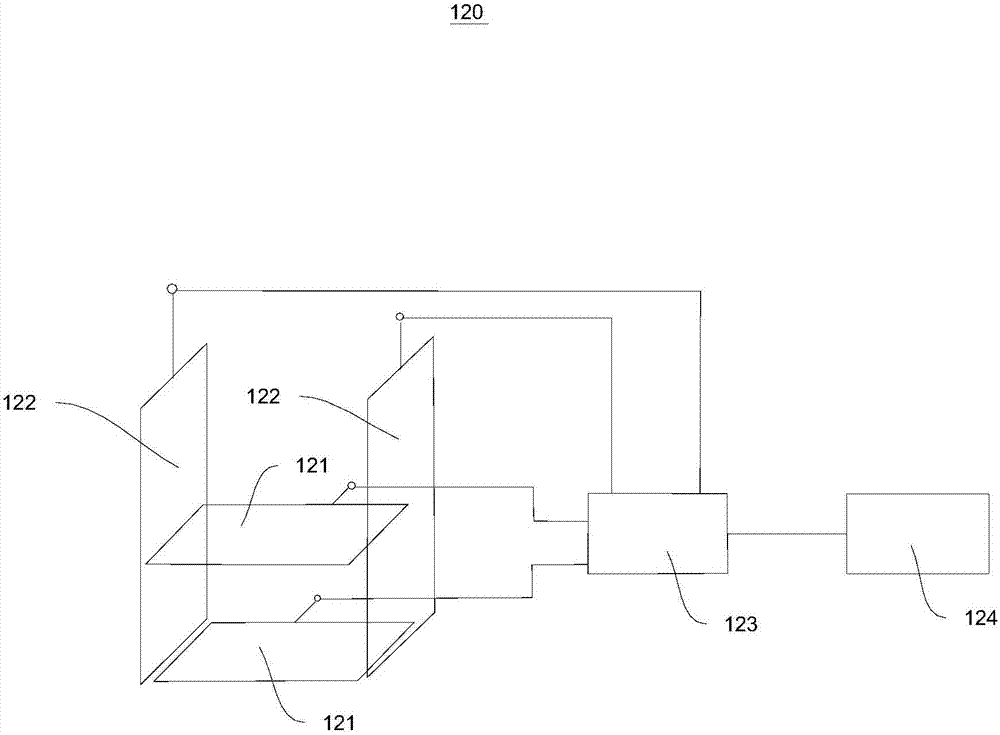

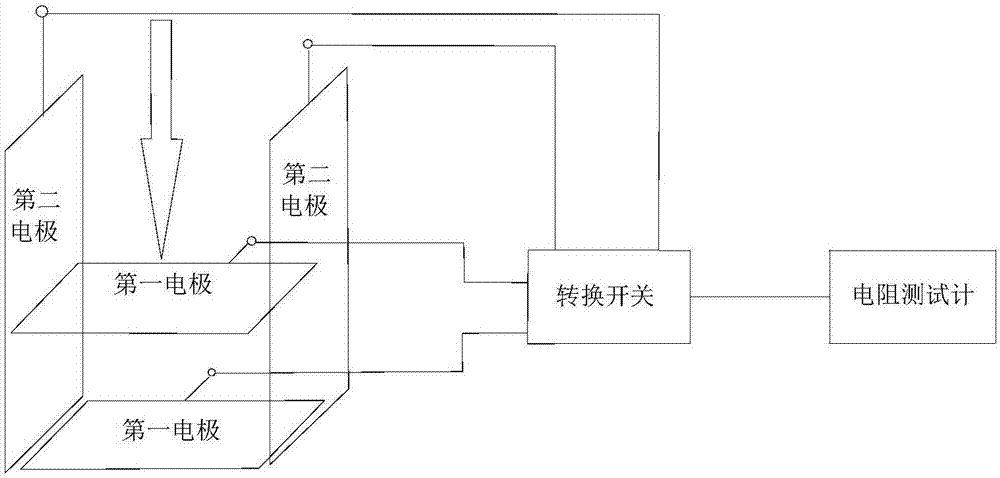

[0030] Please refer to figure 1 , the present embodiment provides a fiber orientation testing device 100, which includes a compression device 110 and an electrode system 120, the electrode system 120 is disposed inside the compression device 110, and is used for testing compressed loose fibers.

[0031] The bulk fiber is compressed by accommodating the bulk fiber in the compressing device 110 , and at the same time, the electrode system 120 detects the horizontal and vertical resistance of the bulk fiber during the compression process. The method realizes the indirect test of the arrangement of the fibers in the aggregate after the fibers in the aggregate of loose fibers are compressed. The fiber orientation degree f given by the device can accurately and comprehensively reflect the arrangement of fibers along the compression direction and vertical compression direction.

[0032] Further, the compression device 110 includes a frame body 111 and a movable part, the movable par...

no. 2 example

[0053] Please refer to the picture Figure 4 , this embodiment provides a fiber orientation testing device 200, which is basically the same as the fiber orientation testing device 100 provided in the first embodiment, except that the position and structure of the movable part are different.

[0054] Specifically, the fiber orientation testing device 200 includes a compression device 210 and an electrode system for compressing loose fibers; the electrode system includes a first electrode 221, a second electrode 222, and a resistance tester; the first electrode 221 is arranged in the horizontal direction In the compression device 210; the second electrode 222 is arranged in the compression device 210 along the direction perpendicular to the first electrode 221; the second electrode 222 can be displaced in the horizontal direction; the resistance tester is electrically connected to the first electrode 221 and the first electrode 221 The two electrodes 222 are used to detect the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com