Electric vehicle charging plug and socket assembly

A charging plug and plug assembly technology, applied in the direction of electrical components, circuits, contact parts, etc., can solve problems such as imperfect internal details, insufficient safety performance, and product arcing, so as to reduce the probability of arcing and improve Safety, the effect of avoiding shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

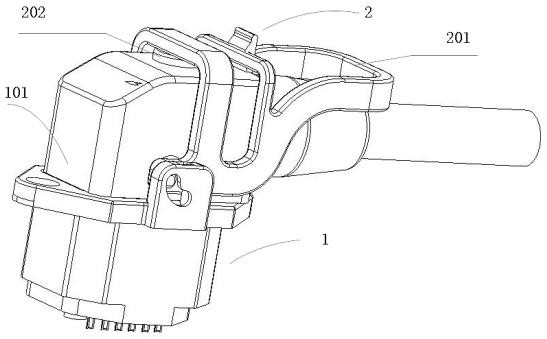

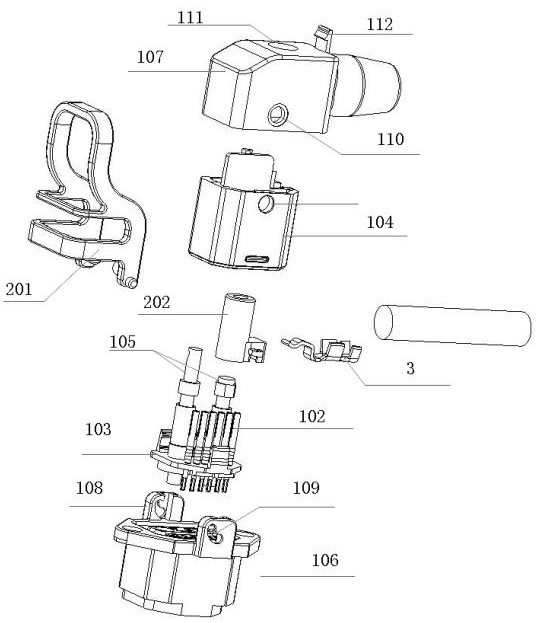

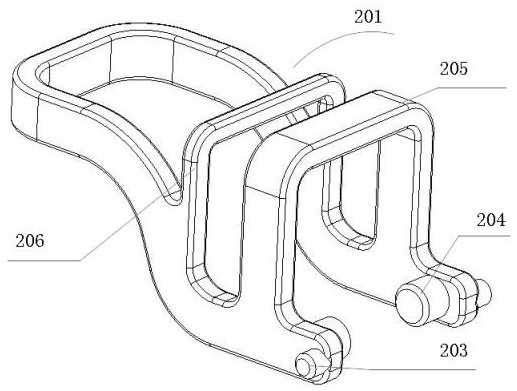

[0020] Figure 1-4 It is a schematic diagram of a preferred embodiment of an electric vehicle charging plug and socket assembly provided by the present invention. Such as Figure 1-4 As shown, the electric vehicle charging plug and socket assembly includes a plug assembly 1 and a locking assembly 2, and the plug assembly 1 includes a housing 101, a PIN needle set 102, a fixing block 103 for fixing the PIN needle set 102, a connector 104 and a conductive wire 105, the PIN needle set 102 is inserted on the fixed block 103, the fixed block 103 is hinged with the connector 104, the conductive wire 105 passes through the connector 104 and connects with the PIN needle set 102, and the housing 101 includes a socket nested on the outer wall of the connector 104 The shell I106 and the shell II107 hinged with the shell I106, the edge of the shell I1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com