Rigid-tough balanced medium-sized hollow container blow molding material

A balanced and medium-sized technology, applied in the field of blow molding materials, can solve problems such as unstable quality, unstable supply, poor rigidity-toughness balance, etc., and achieve excellent rigidity-toughness balance performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Preparation of ethylene-hexene copolymerized polyethylene resin

[0051] When the diluent isobutane is always in circulation, the monomers ethylene and 1-hexene are injected into the loop reactor respectively, and the activated 969ID chromium catalyst is added for reaction, wherein the ethylene feed rate is 25t / h, 1-hexene feed rate is 450kg / h, isobutane feed rate 31.25t / h, catalyst feed rate 360kg / h, reaction temperature 99.5 ℃, until the melt flow velocity of reaction product is 10.5g / 10min, The density is 0.945g / cm 3 , the reaction was stopped to obtain an ethylene-hexene copolymerized polyethylene resin with a weight-average molecular weight of 189,000, a molecular weight distribution index of 4.8, and a 1-hexene content of 0.28 mol%.

[0052] (2) Preparation of medium-sized hollow container blow molding materials

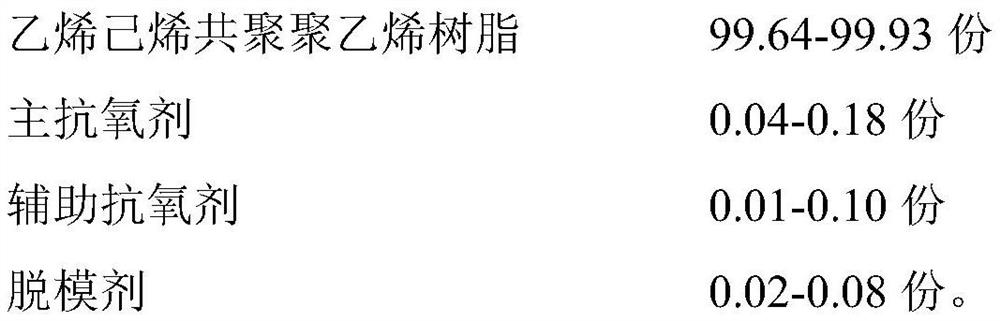

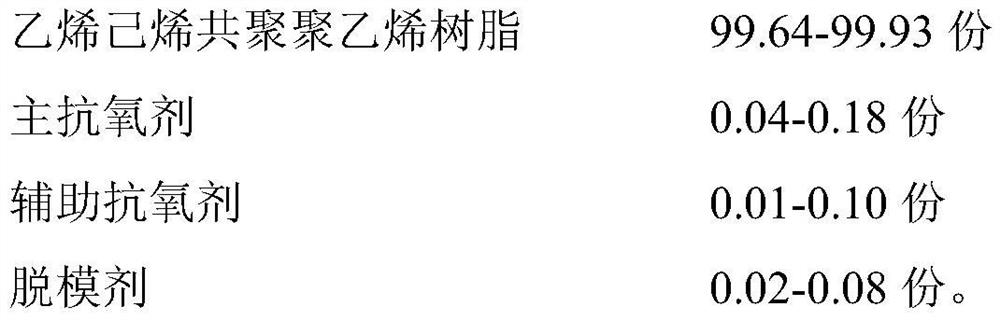

[0053] After mixing 99.82 parts of ethylene-hexene copolymerized polyethylene resin, 0.08 part of primary antioxidant, 0.08 part of auxiliary ant...

Embodiment 2

[0055] (1) Preparation of ethylene-hexene copolymerized polyethylene resin

[0056] When the diluent isobutane is always in circulation, the monomers ethylene and 1-hexene are injected into the loop reactor respectively, and the activated 969ID chromium catalyst is added for reaction, wherein the ethylene feed rate is 36t / h, 1-hexene feed rate is 216kg / h, isobutane feed rate 28.3t / h, catalyst feed rate 270kg / h, reaction temperature 99.7 ℃, until the melt flow velocity of reaction product is 8.5g / 10min, The density is 0.949g / cm 3 , the reaction was stopped to obtain an ethylene-hexene copolymerized polyethylene resin with a weight average molecular weight of 192,000, a molecular weight distribution index of 5.4, and a 1-hexene content of 0.22 mol%.

[0057] (2) Preparation of medium-sized hollow container blow molding materials

[0058] After mixing 99.8 parts of ethylene-hexene copolymerized polyethylene resin, 0.04 parts of primary antioxidant, 0.10 part of auxiliary antio...

Embodiment 3

[0060] (1) Preparation of ethylene-hexene copolymerized polyethylene resin

[0061] When the diluent isobutane is always in a circulating state, the monomer ethylene and 1-hexene are injected into the loop reactor respectively, and the activated 969ID chromium catalyst is added to react, wherein the ethylene feed rate is 30t / h, the feed rate of 1-hexene is 240kg / h, the feed rate of isobutane is 50t / h, the feed rate of catalyst is 300kg / h, and the reaction temperature is 98°C until the melt flow rate of the reaction product is 7.8g / 10min, density 0.946g / cm 3 , the reaction was stopped to obtain an ethylene-hexene copolymerized polyethylene resin with a weight-average molecular weight of 183,000, a molecular weight distribution index of 4.2, and a 1-hexene content of 0.28 mol%.

[0062] (2) Preparation of medium-sized hollow container blow molding materials

[0063] After mixing 99.72 parts of ethylene-hexene copolymerized polyethylene resin, 0.18 parts of primary antioxidant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap