Cross-linked anion exchange membrane as well as preparation method and application thereof

An anion-exchange membrane, cross-linked technology, applied in the field of cross-linked anion-exchange membrane and its preparation, can solve problems such as the need to improve the alkali resistance and mechanical properties, complex preparation methods, and expensive raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention provides the preparation method of cross-linked anion exchange membrane described in above-mentioned technical solution, comprises the following steps:

[0043] (1) p-bromomethylbenzaldehyde, sodium azide and solvent 1 are mixed, and a substitution reaction is carried out to obtain p-azidobenzaldehyde;

[0044] (2) Mix the p-azidobenzaldehyde obtained in the step (1) with trimethylsilylethynyl cobaltocene hexafluorophosphate, catalyst 1 and solvent 2, then add anhydrous potassium carbonate to carry out copper (1) catalyzed azide-alkyne cycloaddition reaction, obtains dicyclocene cobalt cation base benzaldehyde;

[0045] (3) the cobaltocene-based benzaldehyde obtained in the step (2) is mixed with polyvinyl alcohol, catalyst 2 and solvent 3 to carry out an acetalization reaction to obtain cobaltocene-based polyvinyl alcohol;

[0046] (4) mixing the cobaltocene-based polyvinyl alcohol obtained in the step (3) with glutaraldehyde and solvent 4, and t...

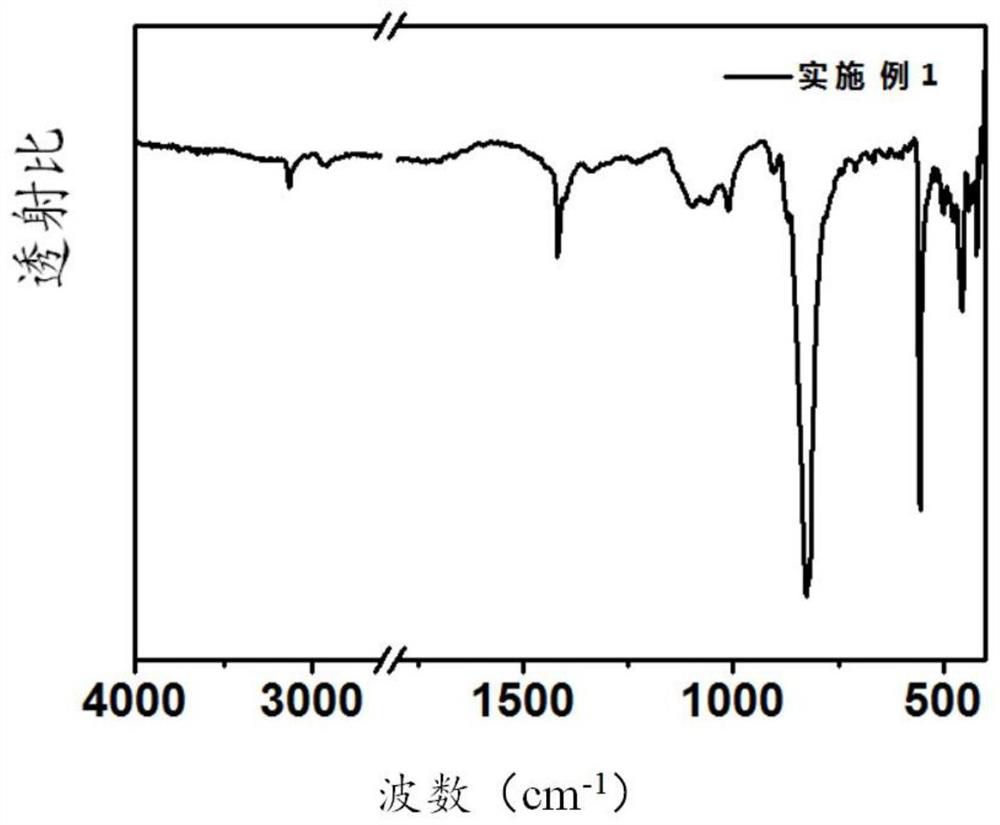

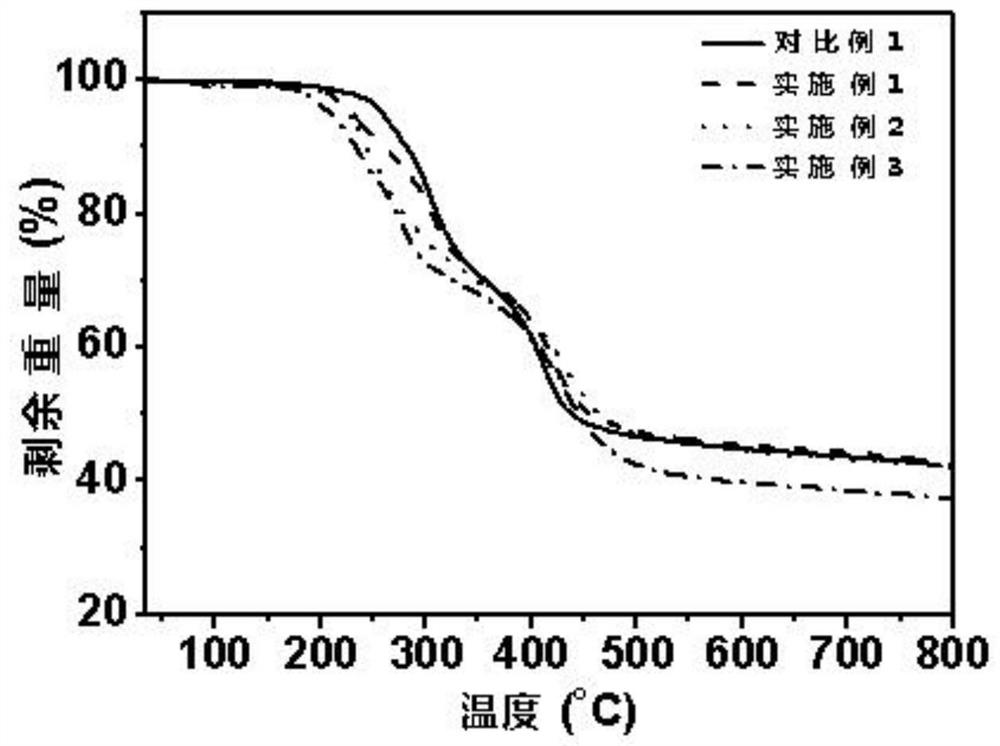

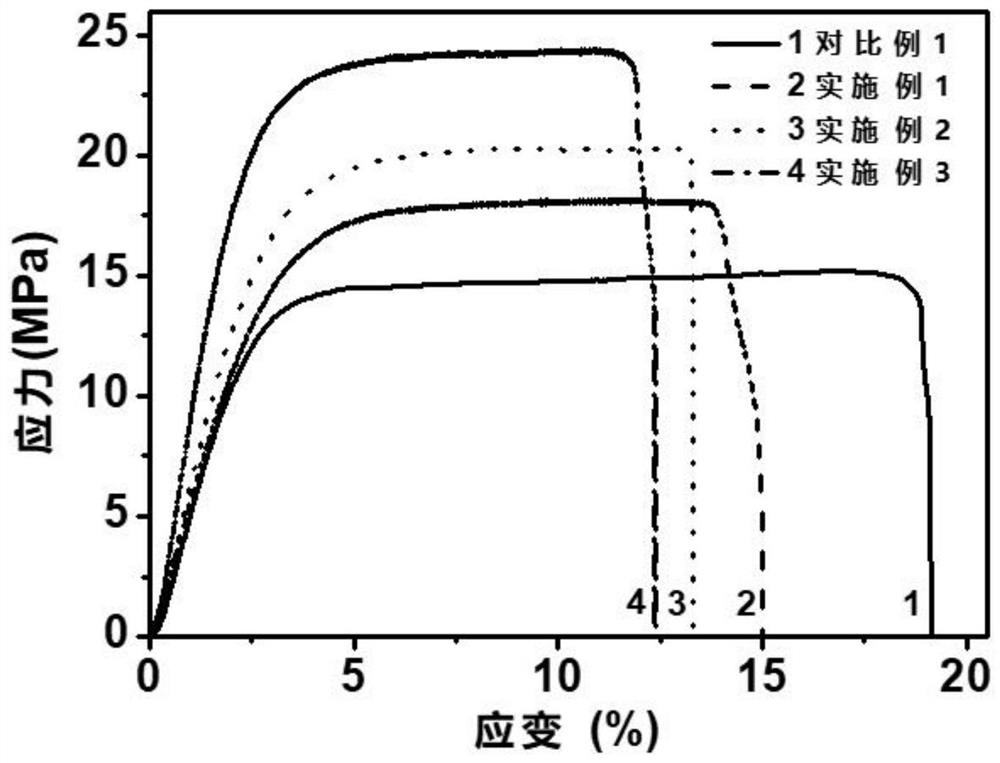

Embodiment 1

[0092] The preparation method of anion exchange membrane is made up of the following steps:

[0093] (1) Add p-bromomethylbenzaldehyde and sodium azide to 15 mL of dimethylformamide and mix, carry out substitution reaction at room temperature for 24 hours, and carry out vacuum distillation to remove dimethyl Formamide, then add 10mL dichloromethane and 10mL deionized water to the distilled product, transfer to a separatory funnel after the solid is completely dissolved, extract and separate liquid three times to obtain an organic phase, combine the organic phases and then back-extract once to obtain Extracted product, and finally add anhydrous Na to the extracted product 2 SO 4 , followed by filtration and rotary steaming to obtain p-azidobenzaldehyde; said p-bromomethylbenzaldehyde, sodium azide and anhydrous Na 2 SO 4 The mass ratio is 1:2:1;

[0094] (2) Dissolve the p-azidobenzaldehyde and trimethylsilylethynyl cobaltocene hexafluorophosphate obtained in the step (1) i...

Embodiment 2

[0100] The preparation method of anion exchange membrane is made up of the following steps:

[0101] (1) Add p-bromomethylbenzaldehyde and sodium azide to 10 mL of dimethylformamide and mix, carry out substitution reaction at room temperature for 12 hours, and carry out vacuum distillation to remove dimethyl Formamide, then add 10mL dichloromethane and 10mL deionized water to the distilled product, transfer to a separatory funnel after the solid is completely dissolved, extract and separate liquid three times to obtain an organic phase, combine the organic phases and then back-extract once to obtain Extracted product, and finally add anhydrous Na to the extracted product 2 SO 4 , followed by filtration and rotary steaming to obtain p-azidobenzaldehyde; said p-bromomethylbenzaldehyde, sodium azide and anhydrous Na 2 SO 4 The mass ratio is 1:1:1;

[0102] (2) Dissolve the p-azidobenzaldehyde and trimethylsilylethynyl cobaltocene hexafluorophosphate obtained in the step (1) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com