Gland of automatic tea leaf rolling machine

A kneading machine and capping technology, which is applied in the field of tea automatic kneading machine capping, can solve the problems of long kneading time, affecting kneading time, small feeding amount, etc., and achieve the effect of improving kneading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

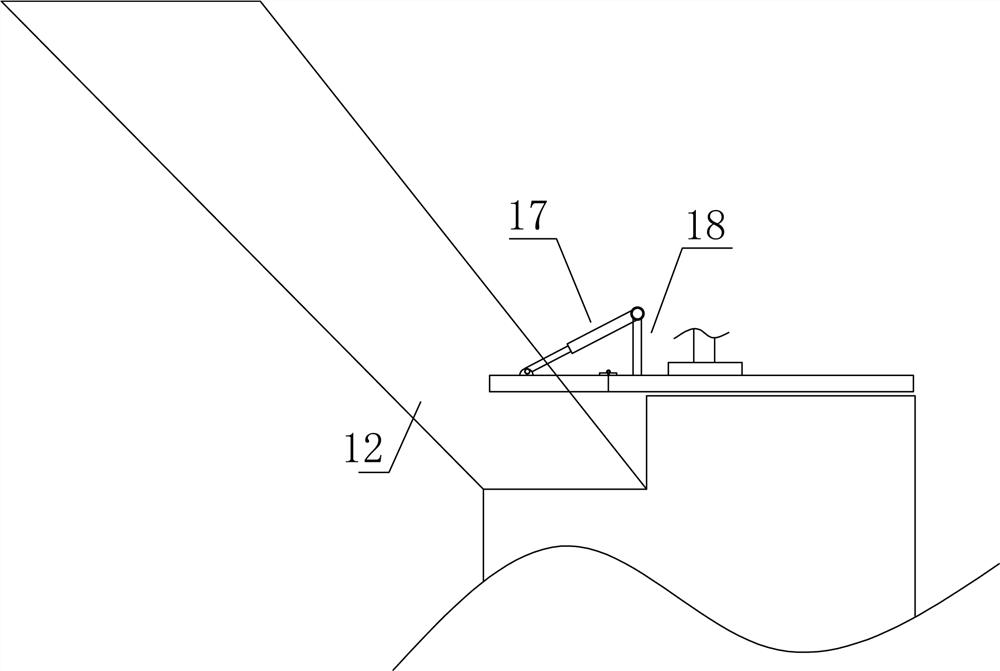

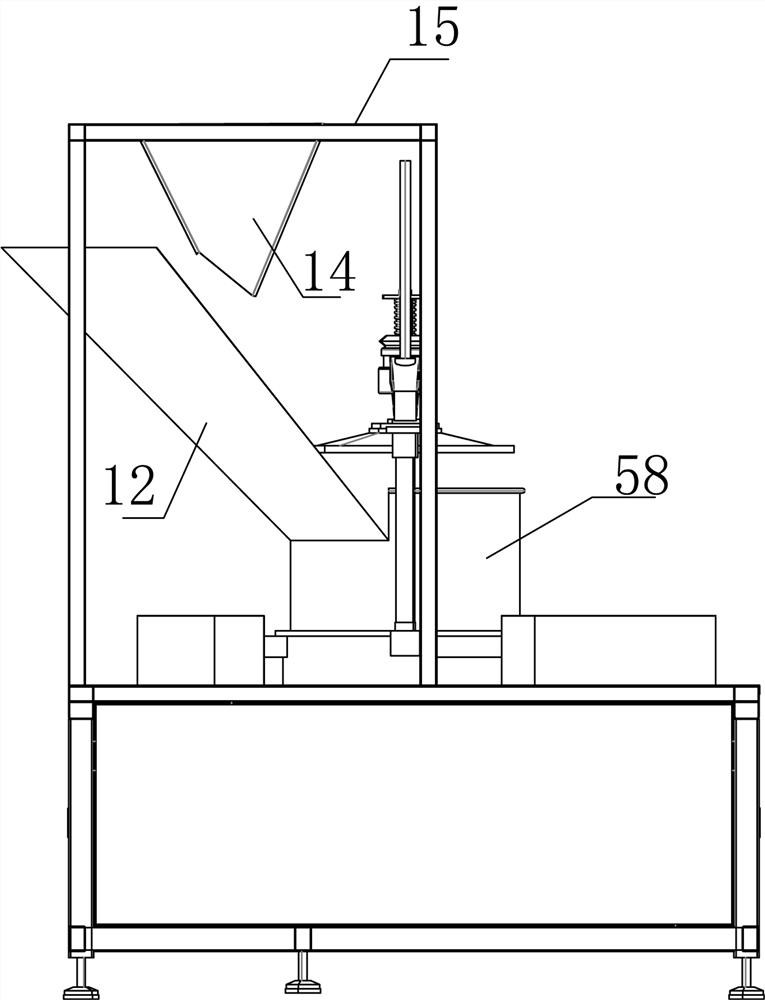

[0029] Such as Figure 3-6 As shown, the feeding structure of the automatic tea rolling machine includes a chute 12 arranged on the grinding body, and the chute 12 is used to introduce tea leaves that need to be twisted into the grinding body. The chute 12 is obliquely arranged on the upper part of the side wall of the grinding body. This technical solution changes the traditional feeding method to direct feeding from the top of the grinding body 58, and the tea leaves that need to be twisted will directly enter the grinding body 58 from the chute 12, which simplifies the feeding steps and increases the amount of feeding, which is helpful Improve kneading efficiency and reduce kneading time.

[0030] Further, as Image 6 As shown, the chute 12 has a fan-shaped structure, and the width of the chute 12 gradually decreases from the top to the bottom. The chute 12 includes an arc-shaped bottom plate 1201, the middle part of which is curved to form a centered material guide chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com