Uniform diffusion type multi-stage composite humidifying system for paper webs

A humidification system and uniform diffusion technology, applied in papermaking, papermaking machines, wetting devices, etc., can solve the problems of poor humidification ratio accuracy, uneven humidification, and small humidification ratio range, and achieve the effect of uniform and rapid humidification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

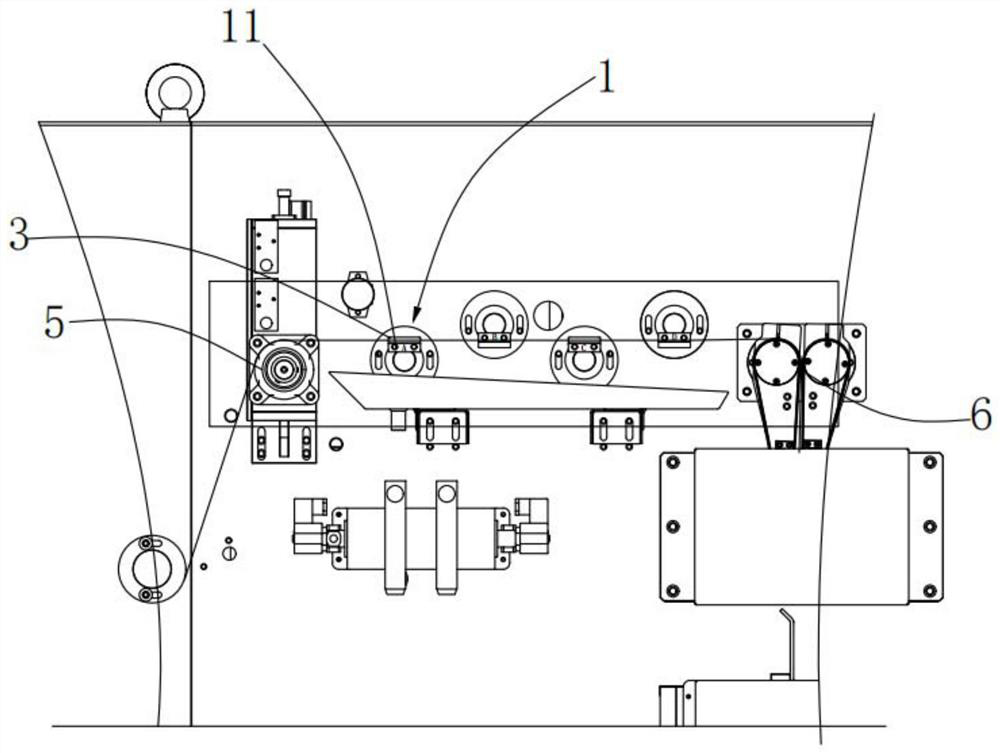

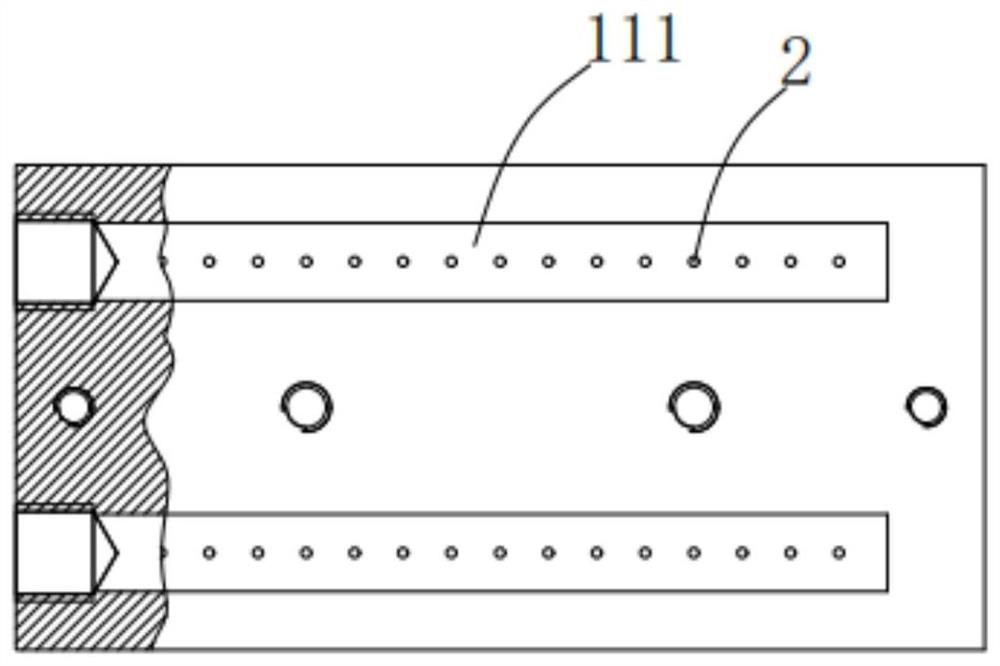

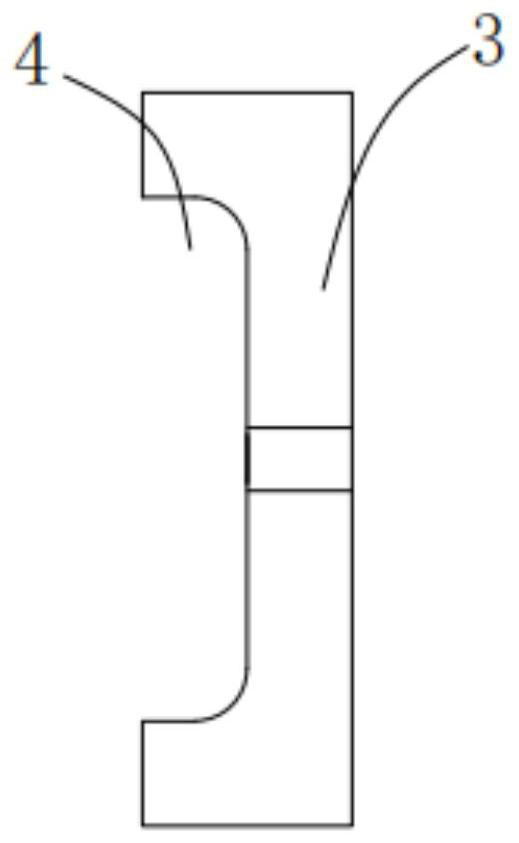

[0033] The humidification module includes four humidification units 1, namely A, B, C, and D. The four humidification units 1 are distributed alternately. Units A and B can be used as pre-humidification modules, and units C and D can be used as deep humidification modules. Module, in the case of low speed and low ratio of toilet paper, the pre-humidification module can be closed, and the toilet paper will pass through the guide roller, the pressure feeding mechanism 5, the limit groove 4 on the four humidification units 1 of A, B, C, and D in sequence. The pinch mechanism 6 humidifies both sides of the toilet paper through the humidifying tubes 111 on the humidifying units 1 of C and D.

Embodiment 2

[0035] The humidification module includes four humidification units 1, namely A, B, C, and D. The four humidification units 1 are distributed alternately. Units A and B can be used as pre-humidification modules, and units C and D can be used as deep humidification modules. Module, for high speed and high ratio of toilet paper, the pre-humidification module and deep humidification module can be turned on at the same time, and the toilet paper will pass through the four humidification units 1 of guide roller, pressure feeding mechanism 5, A, B, C and D in sequence. The limit groove 4 and the pinch mechanism 6 humidify both sides of the toilet paper through the humidifying tubes 111 on the four humidifying units 1 of A, B, C and D.

[0036] To sum up, through the multiple humidification units 1 distributed in a staggered manner, both sides of the paper web are humidified, and the multiple humidification tubes 111 arranged side by side and the humidification holes 2 distributed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com