Distribution network production differentiation operation and maintenance strategy method based on situation awareness

A situation-aware and differentiated technology, applied in data processing applications, instruments, computing, etc., can solve the problems of insufficient perception of equipment evaluation, poor real-time performance of equipment evaluation perception, and low accuracy of equipment evaluation results, so as to achieve real-time data of equipment The effect of perception and evaluation ability, guarantee of perception integrity and result readiness, and improvement of equipment risk perception ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The present invention will be described in further detail below with reference to the accompanying drawings and specific examples.

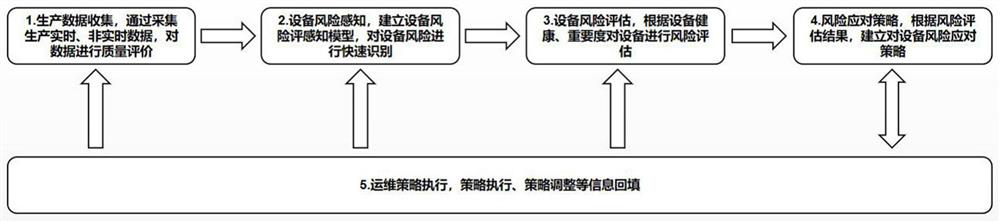

[0048]Situational perceived distribution network production differentiation portability strategy method, combinedfigure 1As shown, including the following steps:

[0049]S1, production data collection, production, real-time, non-real-time data, and quality evaluation of data to provide basic support for device perception. Quality evaluation of data is integrity and validity evaluation of data.

[0050]Step S1 specifically includes the following steps:

[0051]S101, carry out real-time data acquisition, through intelligent distribution room, intelligent field, intelligent pipe, smart equipment and other monitoring technology, data collection, data real-time diagnosis analysis, real-time task, to achieve equipment Real-time perceived ability.

[0052]S102, carry out production business data acquisition, including business data access, and then combined with equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com