A high-current high-voltage vacuum diode

A vacuum diode and high-voltage technology, which is applied in the field of high-current vacuum diodes and high-voltage high-voltage vacuum diodes, can solve the problems of shortened life, reduced withstand voltage of vacuum diodes, flashover along the surface, etc., and achieves reduced surface field strength and uniform electric field distribution , Increase the effect of creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

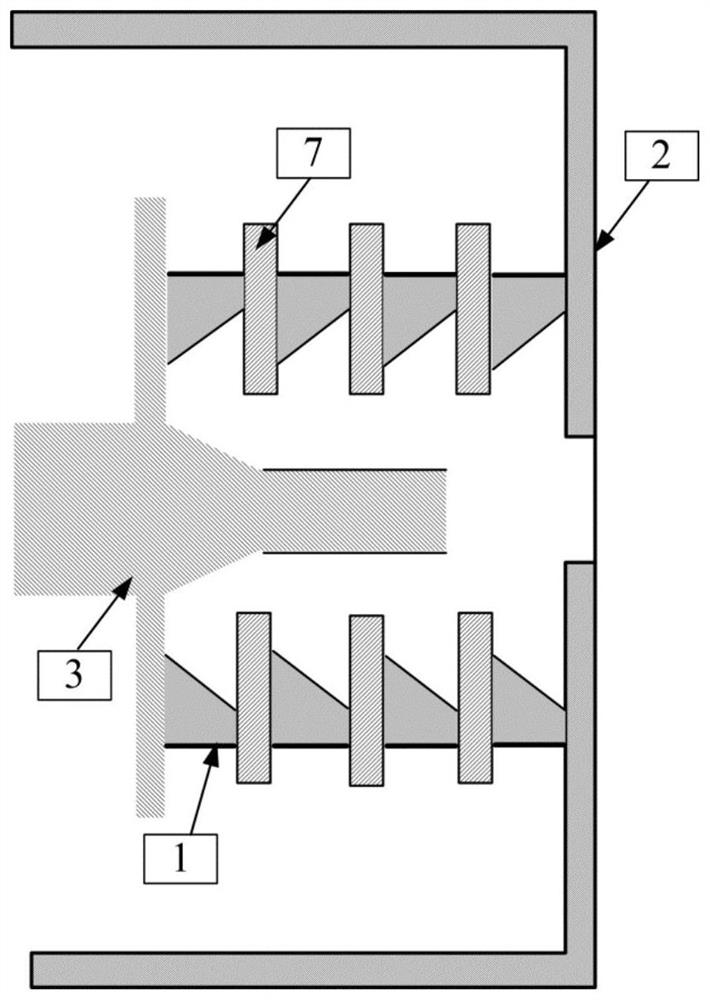

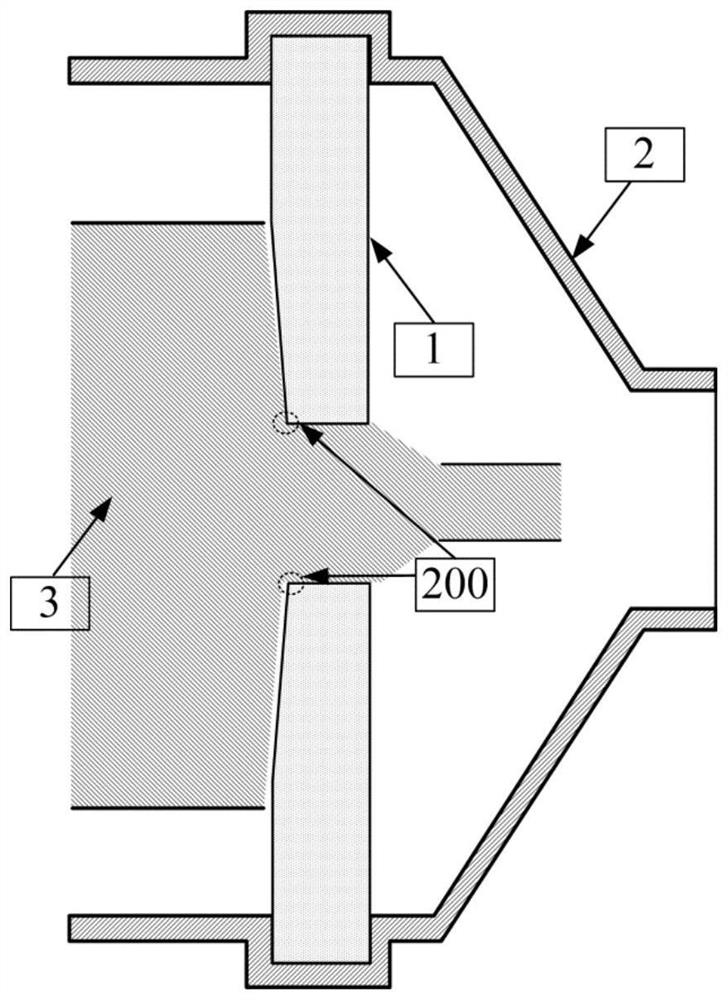

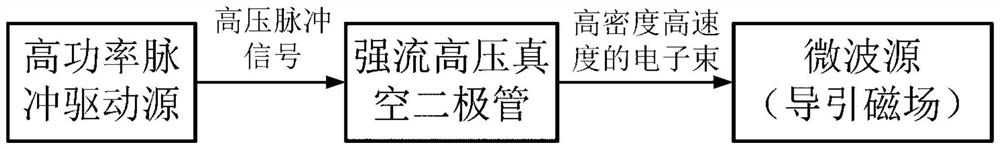

[0049] Such as image 3 As shown, the present invention is composed of an insulator 1, an anode 2, a cathode 3, a shielding ring 4, a flange 5, and a sealing ring 6. The cathode 3, the shielding ring 4, the insulator 1, and the anode 2 are coaxially nested from the inside to the outside, and the insulator The outer edge of 1 is tightly pressed against the inner wall of the anode 2 through the flange 5 and the sealing ring 6, and the cathode 3 passes through the hollow part of the insulator 1 and is connected with the high-power pulse driving source 100 of the previous stage. The end connected to the high-power pulse driving source 100 of the present invention is defined as the left end, and the end connected to the microwave source 102 of the present invention is defined as the right end. The shielding ring 4 is screwed on the right end of the cathode 3 through metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com