Bone support type upper jaw rear long implant implantation guide seat based on three-dimensional printing technology

A 3D printing and supportive technology, applied in dental implants, dental restorations, medical science, etc., can solve the problems of long overall time of navigation surgery, insufficient strength of the guide plate, and errors between the design position and the actual position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

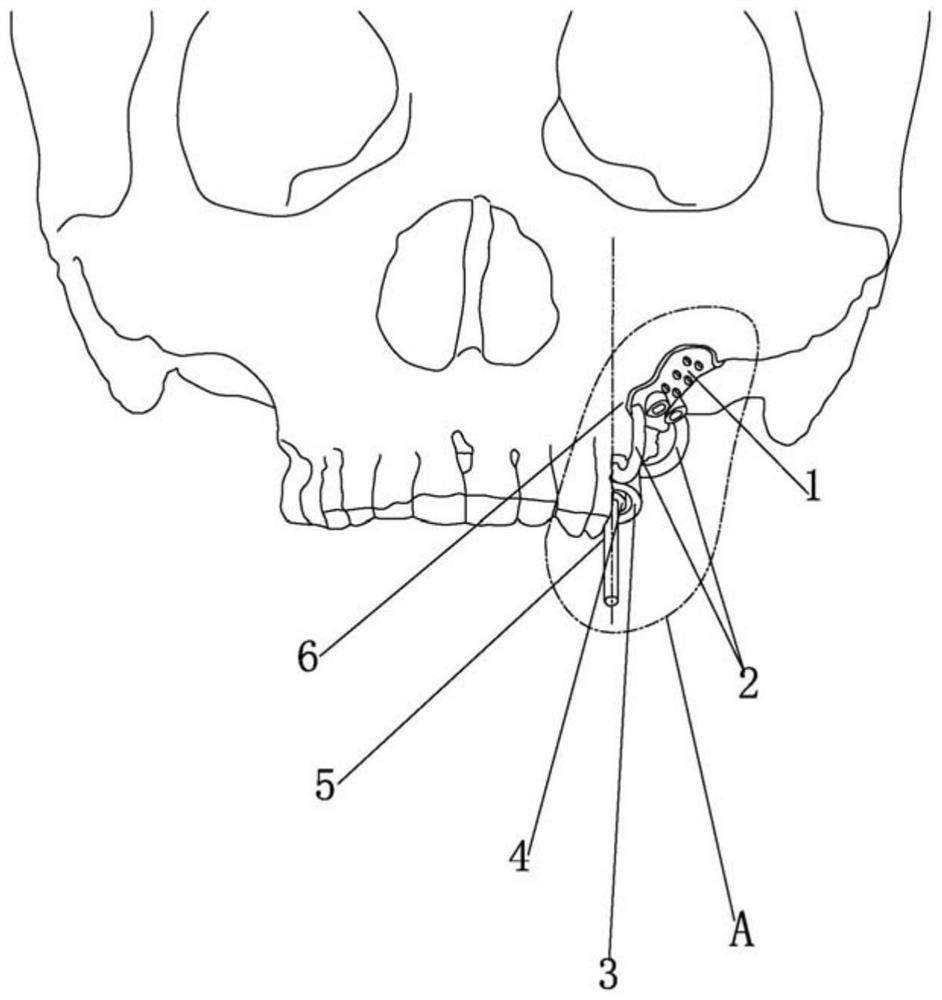

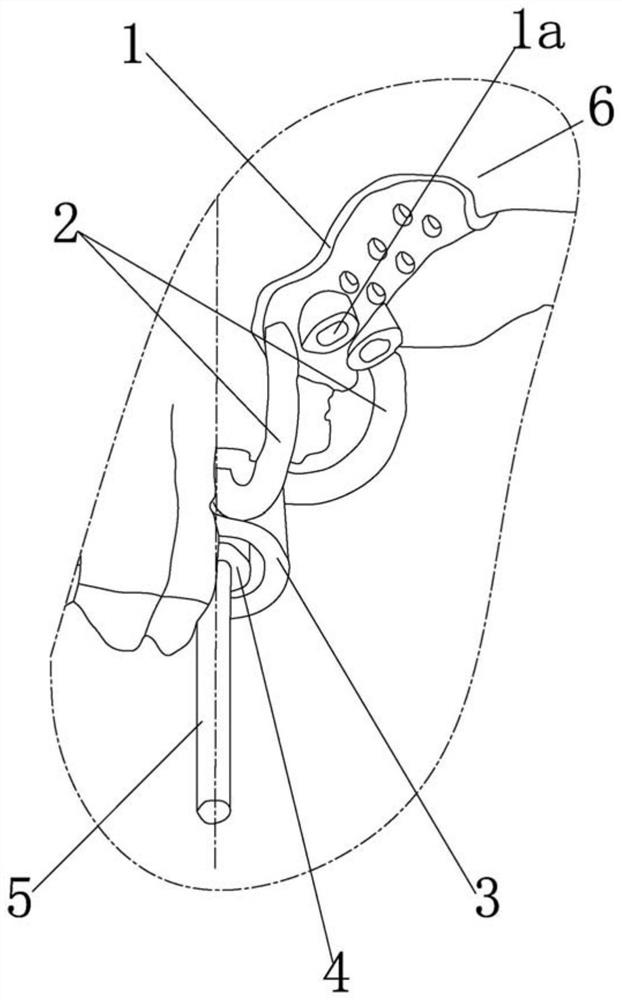

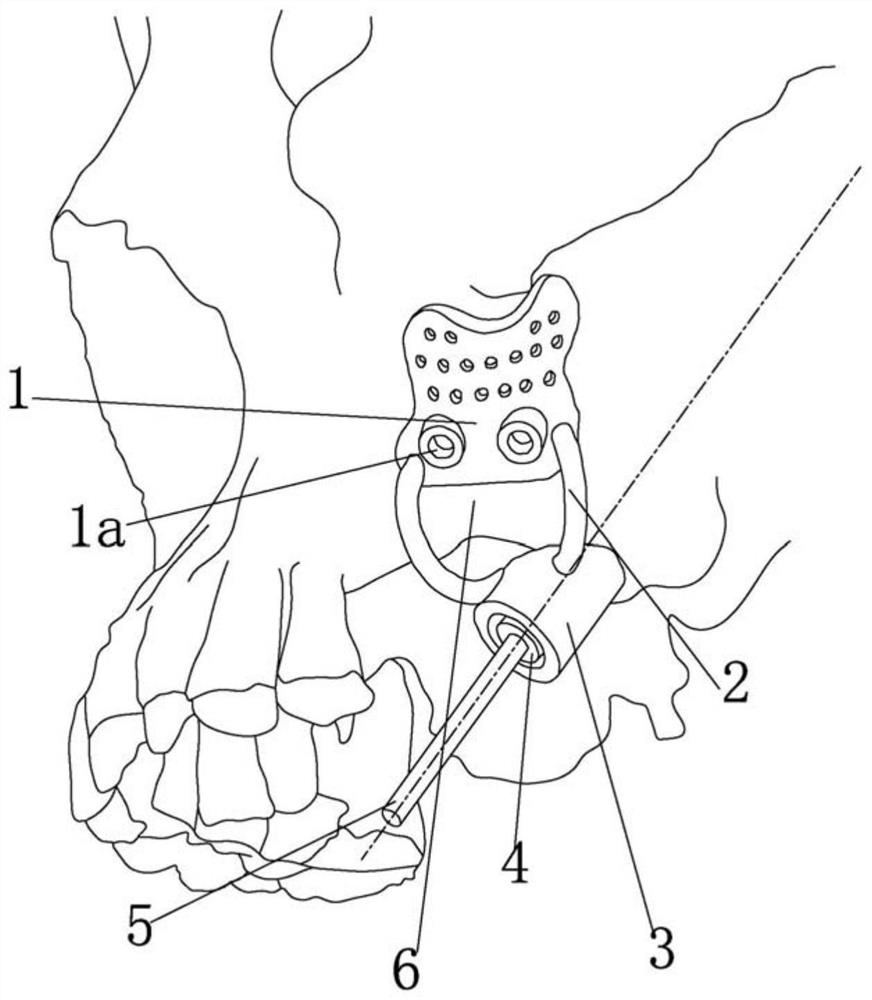

[0024] Such as Figure 1-3 As shown, the first embodiment is used for the implant surgery of the wing plate, and the bone-supported maxillary posterior long implant implant guide seat based on 3D printing technology includes:

[0025] The maxilla fixation plate 1 fits the maxilla 6 in place;

[0026] The implant guide ring part 3 is set as a circular sleeve structure and is coaxial with the implant drill needle 5. The implant guide ring part 3 is located under the maxilla 6 and faces the implant position of the maxilla 6. In this embodiment, the implant guide ring One axial end of the part 3 is facing and close to the implantation position of the maxilla 6;

[0027] The guide piece 4, the guide piece 4 is coaxially and detachably inserted into the planting guide ring part 3, and has an axially penetrating hole that accommodates the planting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com