Pot Seedling Transplanting Mechanism with Noncircular Gear Double Planetary Gear System

A double planetary gear train, non-circular gear technology, applied in transplanting machinery, belt/chain/gear, mechanical equipment and other directions, can solve the problems of complex mechanism, harsh working environment, damage to seedling roots, etc., achieving a high degree of mechanization, The effect of taking the seedling trajectory and posture is accurate, and the root system is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

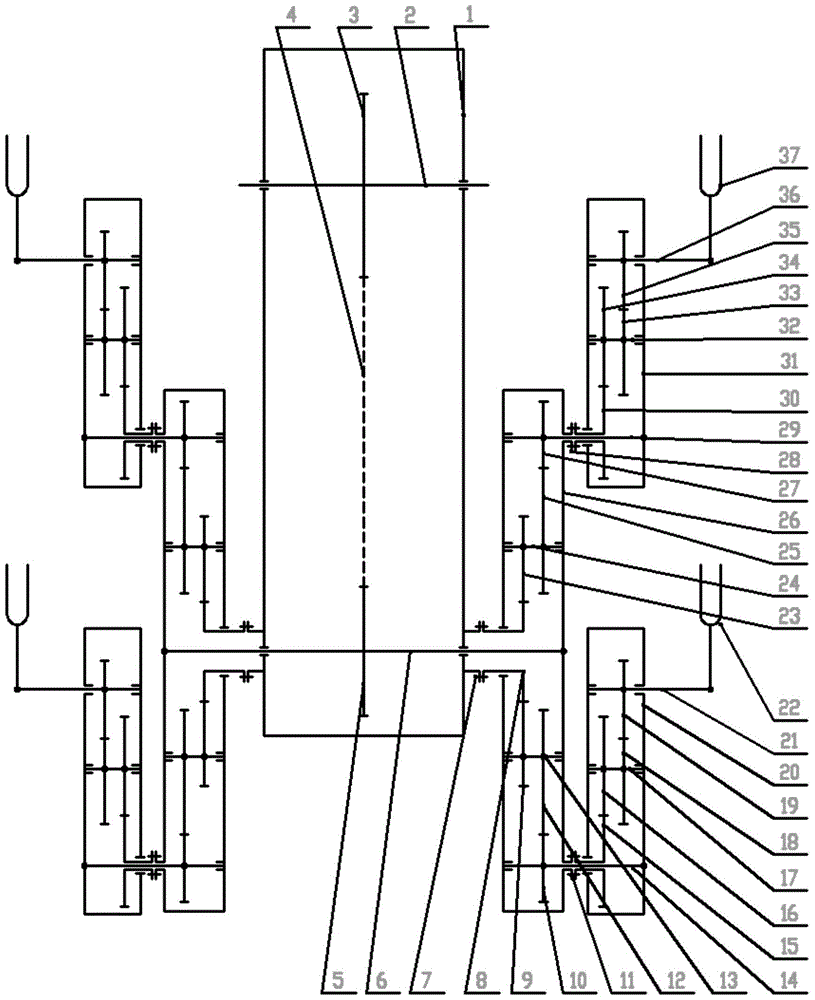

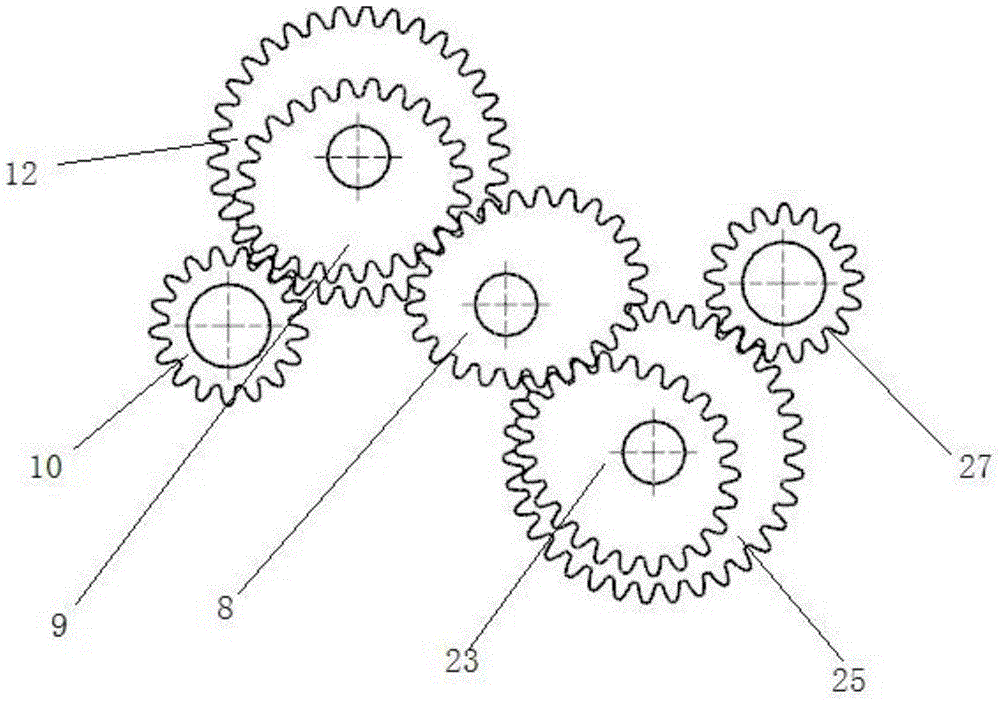

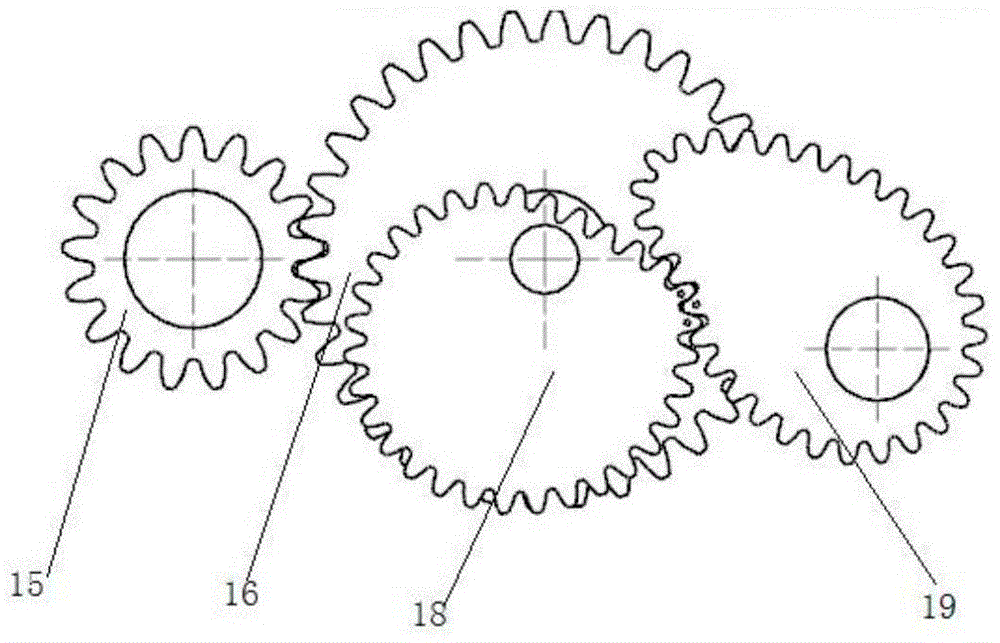

[0028] Such as figure 1 , 2 As shown in and 3, the non-circular gear double planetary gear train pot seedling transplanting mechanism includes a power drive box 1, a driving sprocket shaft 2, a driving sprocket 3, a chain 4, a central sprocket 5, a central shaft 6, and a main planetary gear train , the upper secondary planetary gear train, the lower secondary planetary gear train, the upper planting arm 37 and the lower planting arm 22; the drive sprocket shaft 2 and the center shaft 6 are supported at both ends of the power drive box 1 through bearings; fixedly connected to the drive sprocket shaft 2 The driving sprocket 3 is connected with the central sprocket 5 fixedly connected to the central shaft 6 through a chain 4; the two ends of the central shaft 6 are symmetrically provided with two main planetary gear trains, an upper secondary planetary gear train and a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com