A device for preventing scum crusting in anaerobic reactor

A scum and crust technology, applied in the field of anaerobic reactors, can solve the problems of complex device and energy consumption, and achieve the effects of improving stability, improving safety and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object of the present invention, the technical solution and advantages more clearly understood, the following in conjunction with the accompanying drawings and embodiments, the present invention will be further elaborated in detail. It should be understood that the specific embodiments described herein are merely used to explain the present invention and are not intended to qualify the present invention.

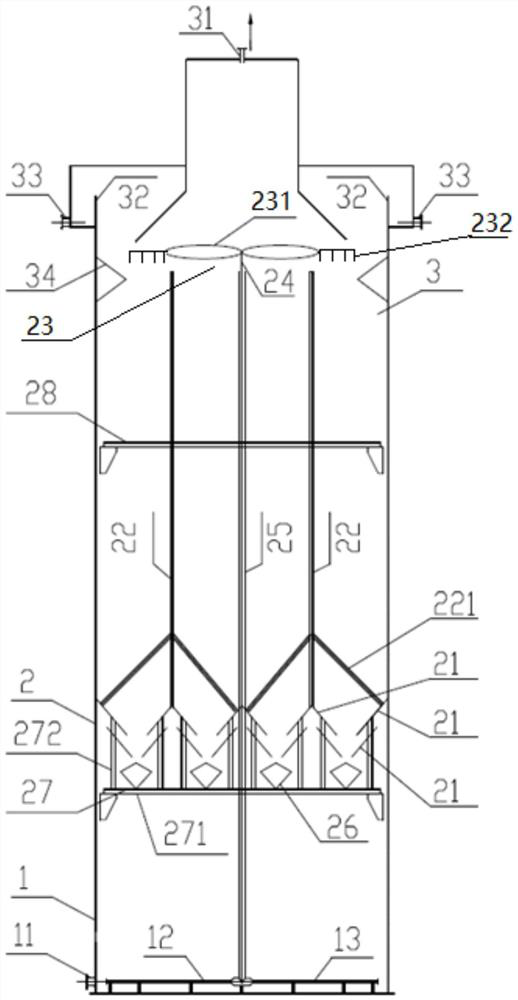

[0031] In a specific embodiment of the present invention, provided such as Figure 1A device shown to prevent scum crusting of anaerobic reactor, comprising an inlet zone 1 disposed at the bottom, a first three-phase separation zone 2 disposed in the middle and a second tertiary phase separation zone 3 at the top; Thereinto:

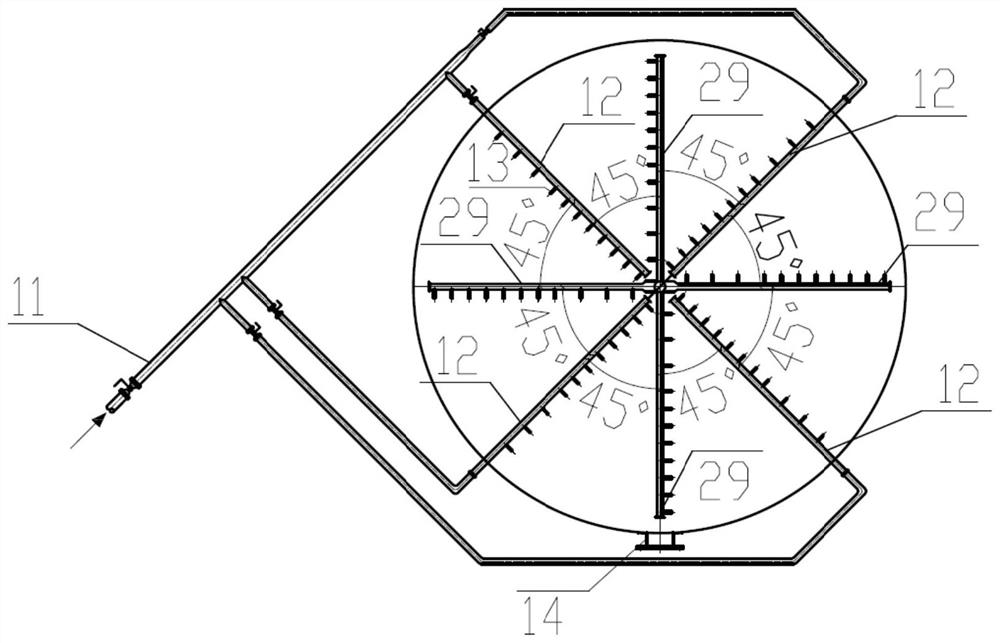

[0032] The inlet area 1 includes an inlet pipe 11, a water distributor 12 connected to the inlet pipe 11; The inlet area 1 is also provided with anaerobic sludge. The water distributor 12 includes several water distribution pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com