Building structure suitable for building high-rise building with multi-story building

A technology for high-rise buildings and multi-storey buildings, which is applied in the direction of building construction and construction, and can solve problems such as inability to perform fast and stable splicing, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

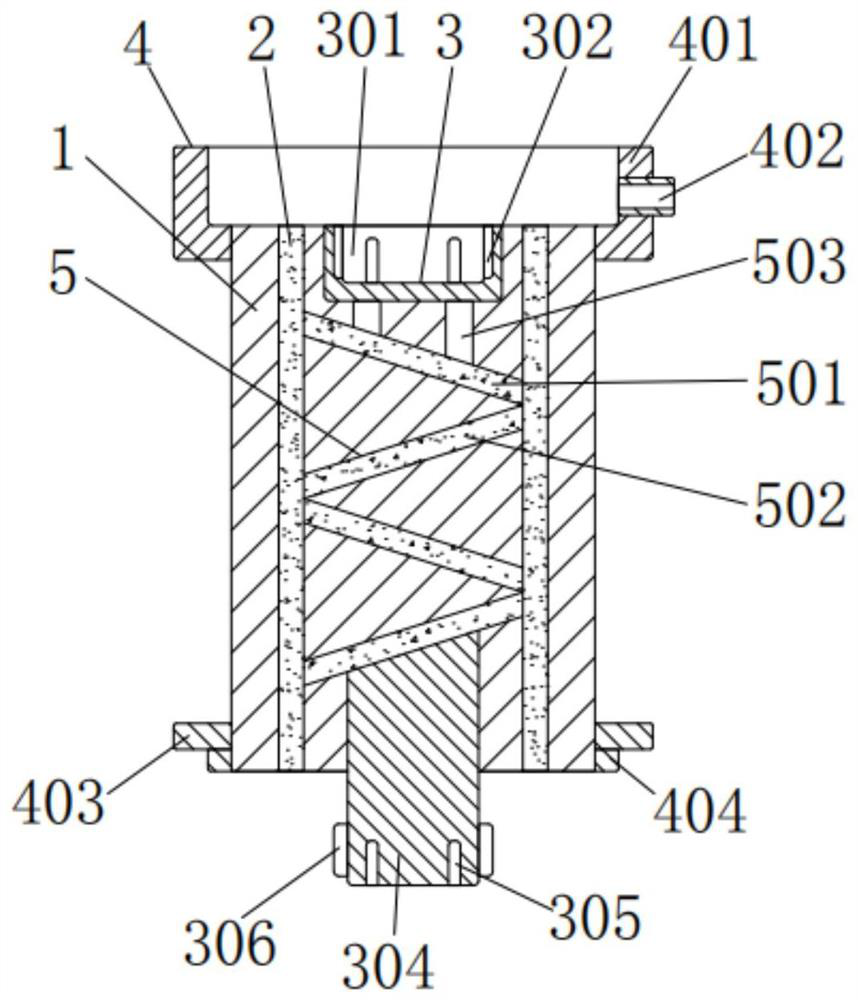

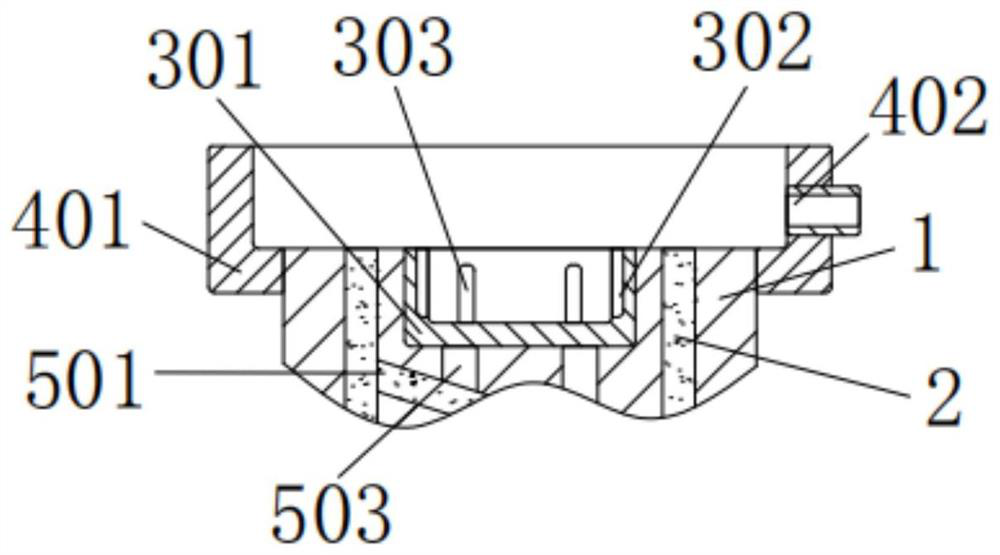

[0031] A building structure suitable for building high-rise buildings in multi-storey buildings, comprising a prefabricated concrete support column body 1, the interior of the prefabricated concrete support column body 1 is wrapped with a steel frame 2, the top of the outer wall of the prefabricated concrete support column body 1 and The bottom is equipped with a docking mechanism 3. The docking mechanism 3 includes a first groove frame 301, a chute 302, a rod body 303, a column body 304, an inner cavity 305 and a slider 306. The first groove frame 301 is set on the assembled concrete support. The top of the outer wall of the column body 1, the first groove frame 301 is connected to the top of the outer wall of the prefabricated concrete support column body 1, the left and right sides of the inner wall of the first groove frame 301 are provided with chute 302, and the two chute 302 are respectively It is processed on the left side and the right side of the inner wall of the fir...

Embodiment 2

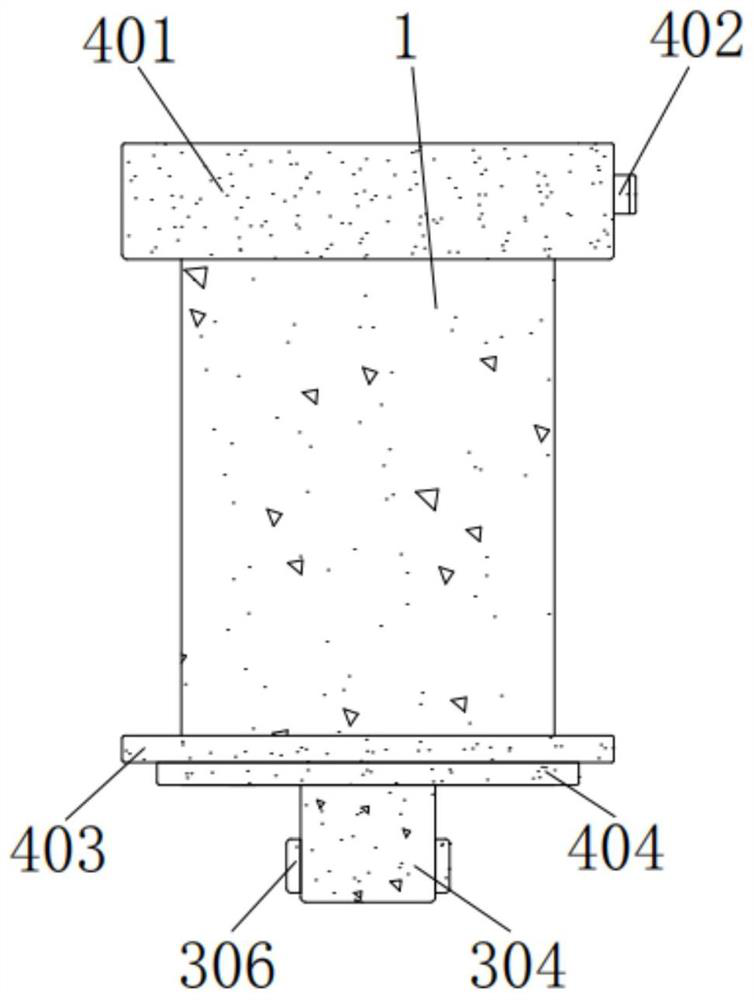

[0033] As an option, see figure 1 , 2, 3 and 5, are applicable to the building structure of multi-storey building building high-rise building, the top and the bottom of the outer wall of prefabricated concrete supporting column body 1 are all provided with connecting mechanism 4, and connecting mechanism 4 comprises second groove frame 401, concrete pouring The opening 402, the first horizontal plate 403 and the second horizontal plate 404, the second groove frame 401 is arranged on the top of the outer wall of the prefabricated concrete support column body 1, the inner wall of the second groove frame 401 and the prefabricated concrete support column body The outer walls of 1 are fixed together, and the right side of the inner wall of the second groove frame 401 is provided with a concrete pouring opening 402, and the concrete pouring opening 402 can support the first horizontal plate 403 and the second After the horizontal plate 404 is attached to the second groove frame 401...

Embodiment 3

[0036] As an option, see figure 1 , 3 , 4 and 5, are applicable to the building structure of multi-storey building building high-rise building, the inner wall of reinforcement frame 2 is provided with reinforcing mechanism 5, and reinforcing mechanism 5 comprises first reinforcing bar 501, second reinforcing bar 502 and the 3rd reinforcing bar 503, a plurality of The first steel bar 501 and the second steel bar 502 are arranged on the inner wall of the steel bar frame 2, and the multiple first steel bars 501 and the second steel bars 502 are fixed in pairs, and the left and right sides of the multiple first steel bars 501 and the second steel bars 502 are respectively Fixed on the left and right sides of the inner wall of the steel frame 2, the bottom second steel bar 502 is fixed to the top of the column 304, and the top of the top first steel bar 501 is fixed with two third steel bars 503, two third The top of the reinforcing bar 503 is affixed to the bottom of the outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com