Calibration device and method for line scanning imaging

A line scanning and calibration technology, applied in the field of online scanning imaging, can solve problems such as inconsistent imaging states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

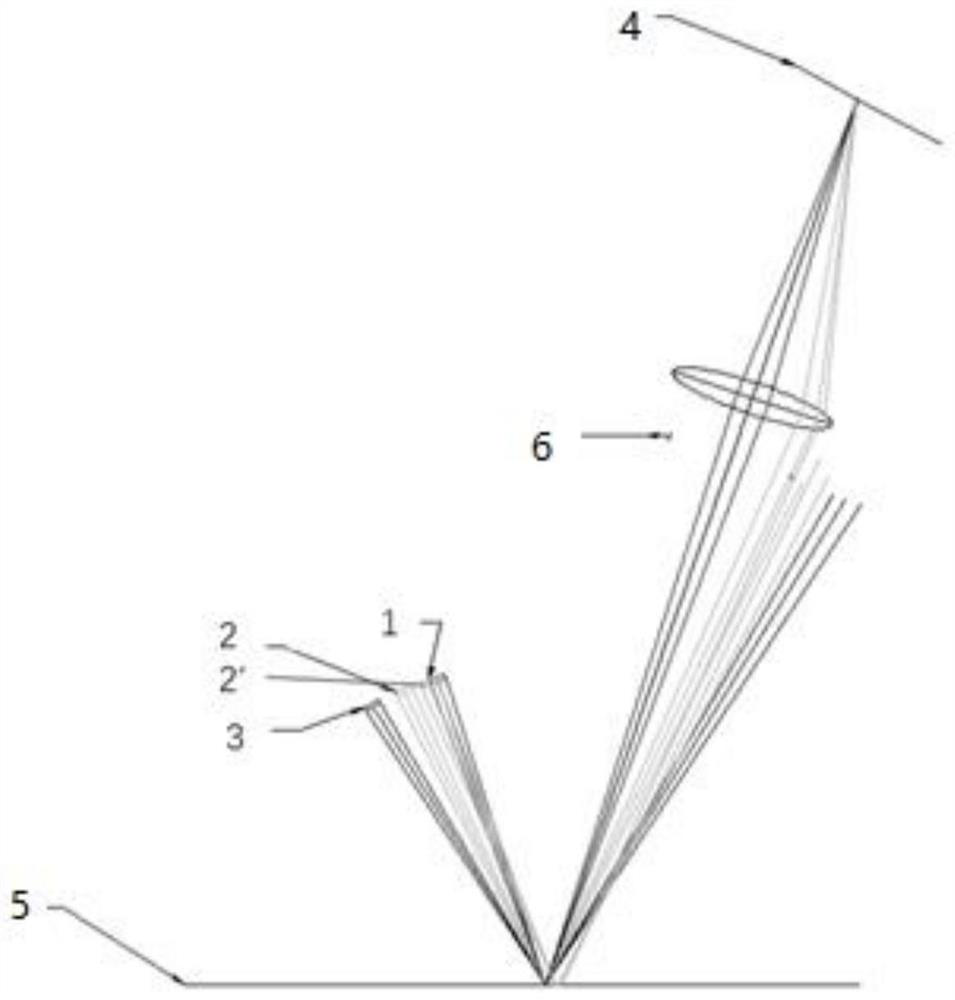

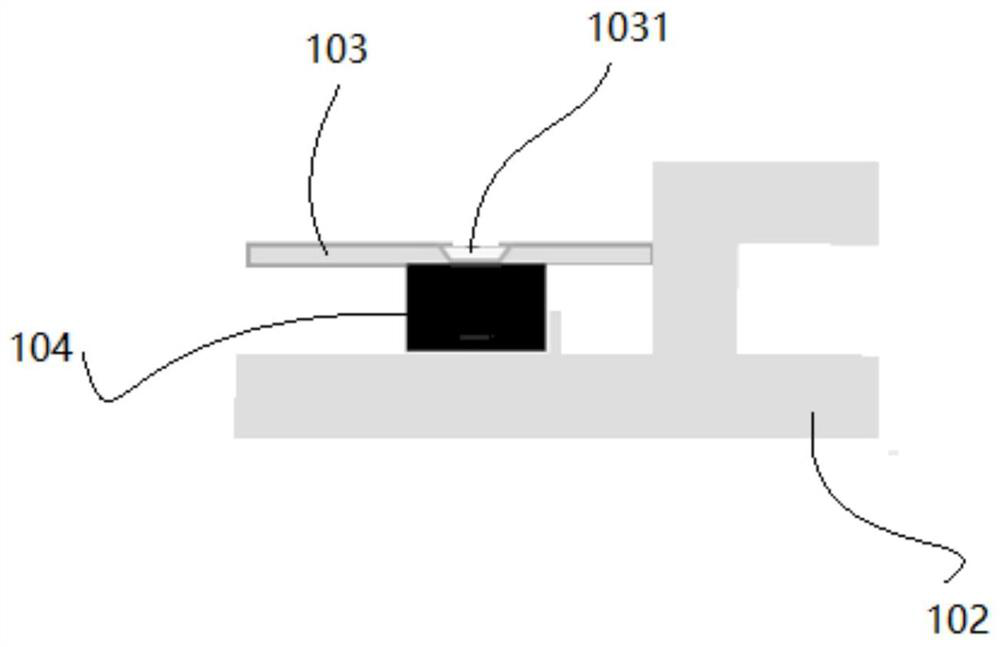

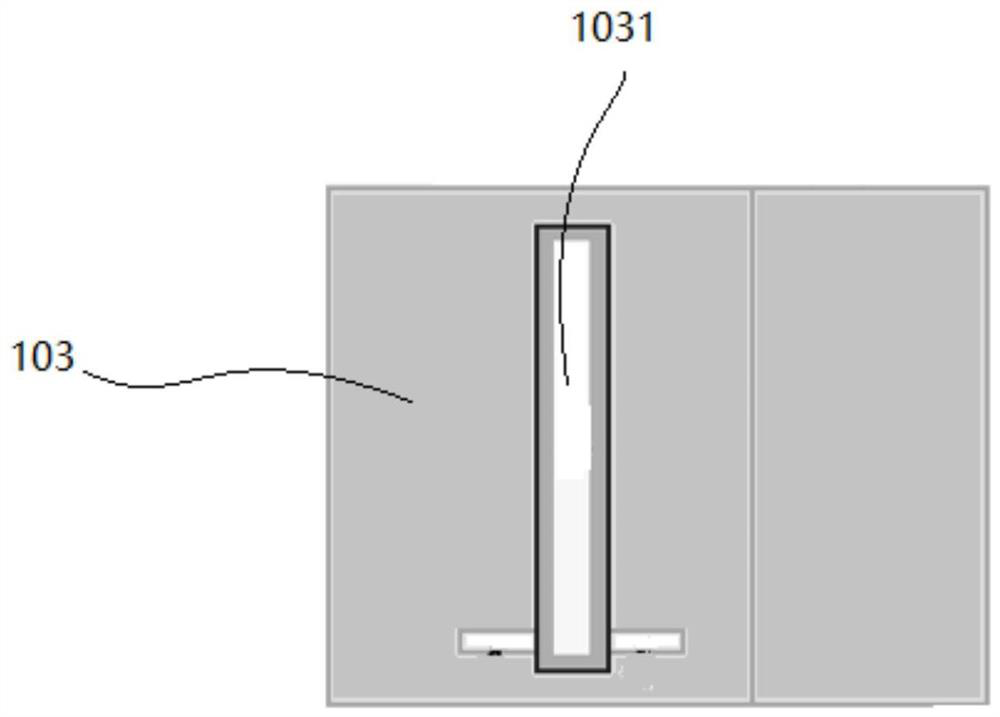

[0055]In order to better understand the present application scheme, the technical solutions in the present application embodiment will be described in connection with the drawings in the present invention, and the technical solutions in the present application will be clear and completely described.

[0056]In some processes and claims in the present application and some of the above-described drawings, a plurality of operations occurring in a particular order, but it should be understood that these operations may not be followed in the order in this article. Execution or parallel execution, the serial number, such as 101, 102, etc., are simply used to distinguish various different operations, and the sequence number does not represent any execution order. Additionally, these processes can include more or less operations, and these operations can be performed in order or in parallel. It should be noted that "first", "second", etc. in this paper is to distinguish between different messa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com