High-stability grating splicing five-dimensional adjusting mechanism

A five-dimensional adjustment, high stability technology, applied in optics, optical components, installation and other directions, can solve problems such as the inability to maintain long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be further described in detail according to the accompanying drawings.

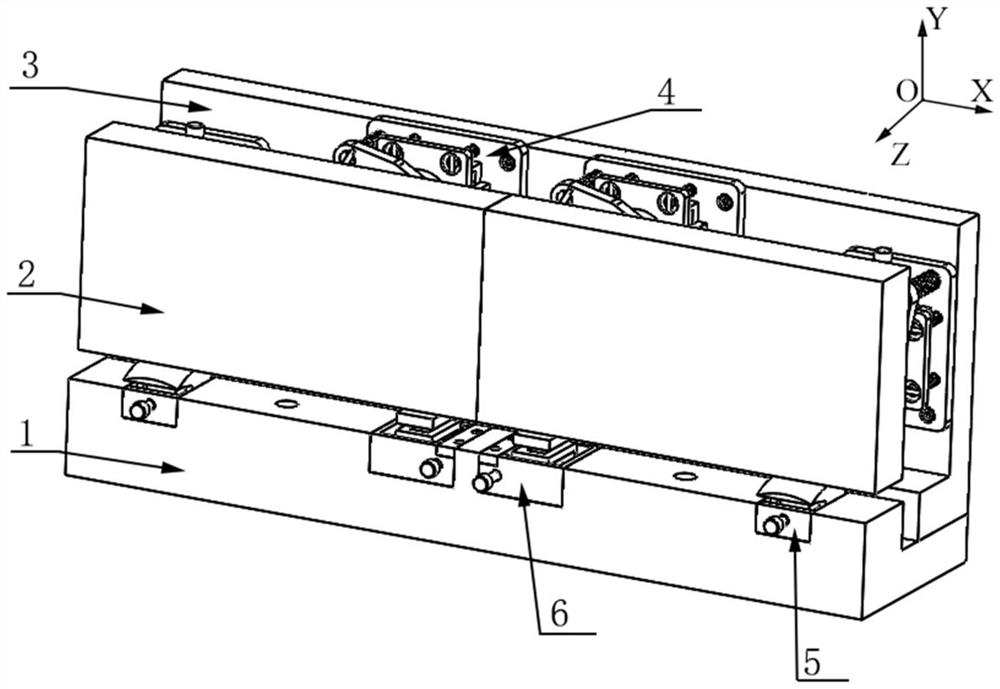

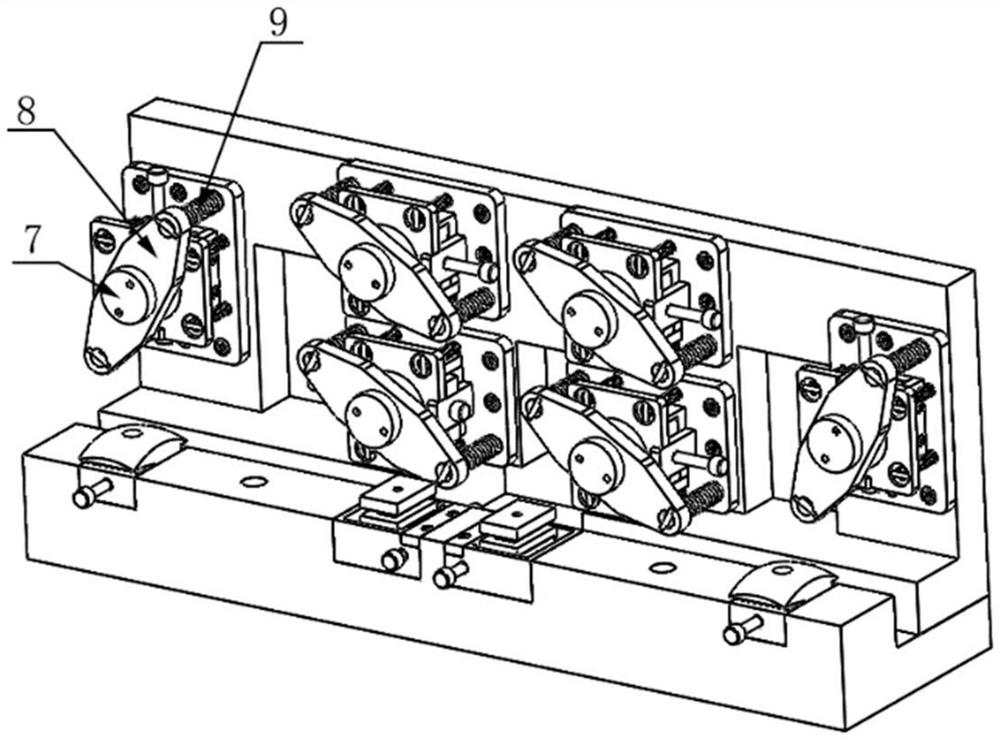

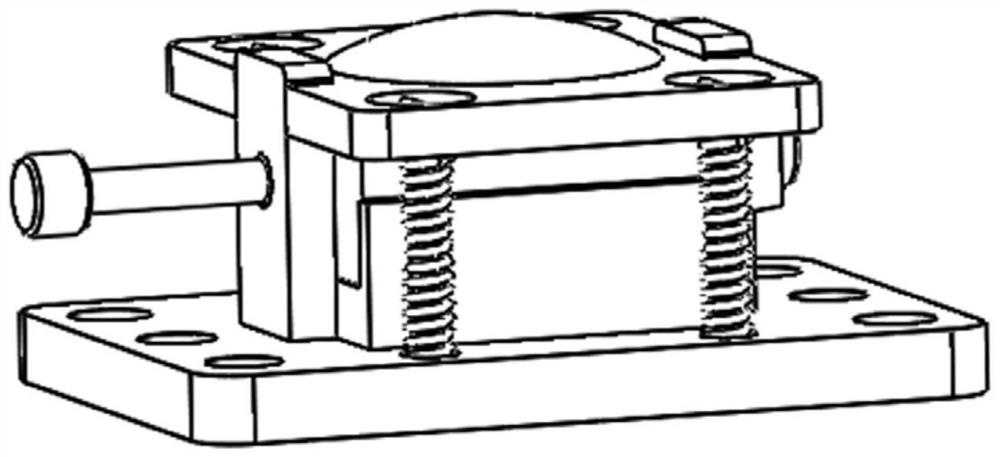

[0034] This embodiment provides a figure 1 The shown double grating stitching five-dimensional stable fine-tuning mechanism. The double grating splicing five-dimensional stable fine-tuning mechanism includes a spliced grating unit 2, a base 1, a base plate 3, a stable fine-tuning self-locking mechanism 4, a stable fine-tuning mechanism 5, a slidable ball hinge fine-tuning mechanism 6, and a spring pretensioning component. In this embodiment, the base 1 and the substrate 3 are vertically distributed as a fixed reference for grating splicing.

[0035] In the process of grating splicing, in order to ensure the coplanarity of the two spliced gratings and the parallelism and full periodicity of the grating grooves, it is necessary to adjust the five-dimensional degrees of freedom of the spliced grating units, respectively degrees of freedom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com