Touch sensor and method of manufacturing the same

一种触摸传感器、接触孔的技术,应用在仪器、电数字数据处理、数据处理的输入/输出过程等方向,达到低电阻、容易实现的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

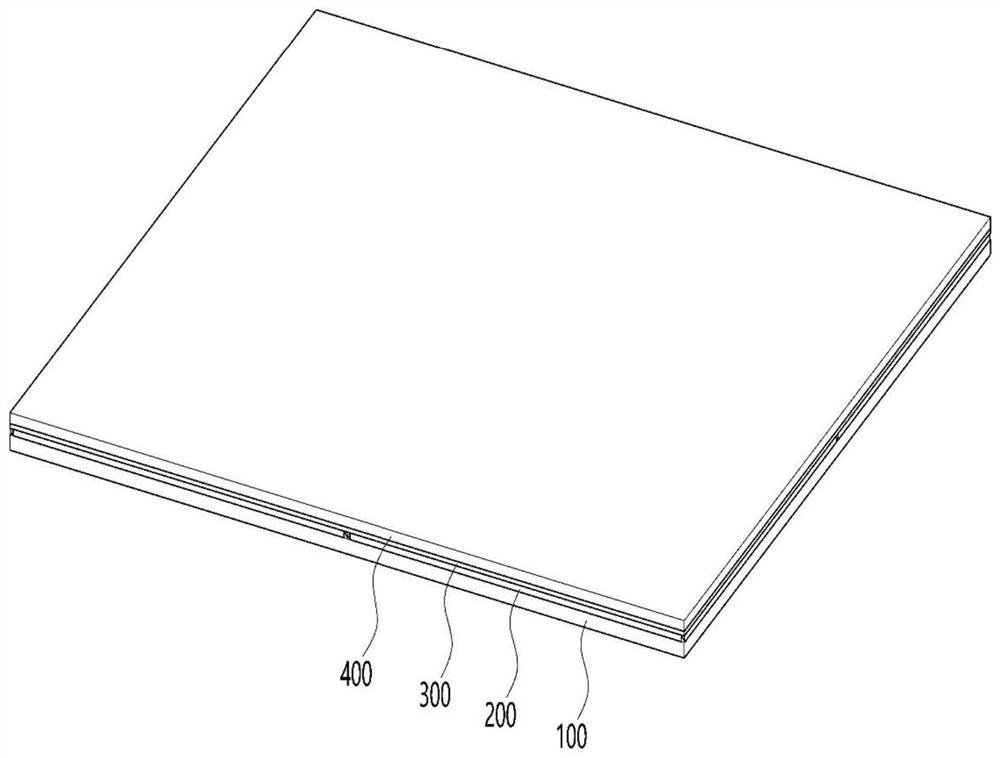

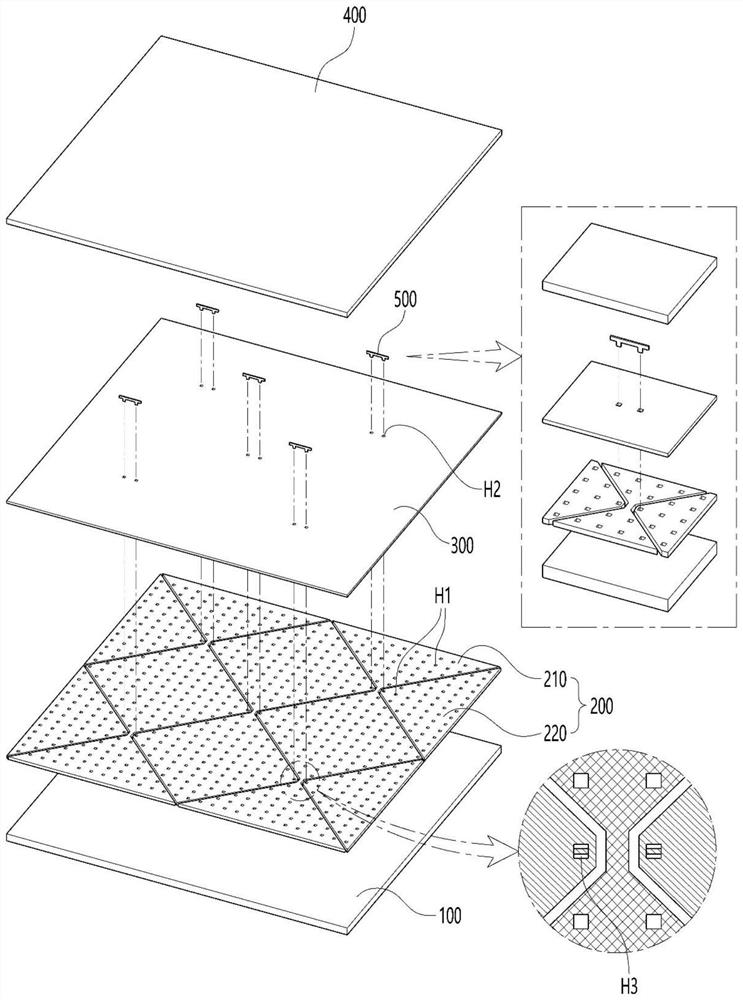

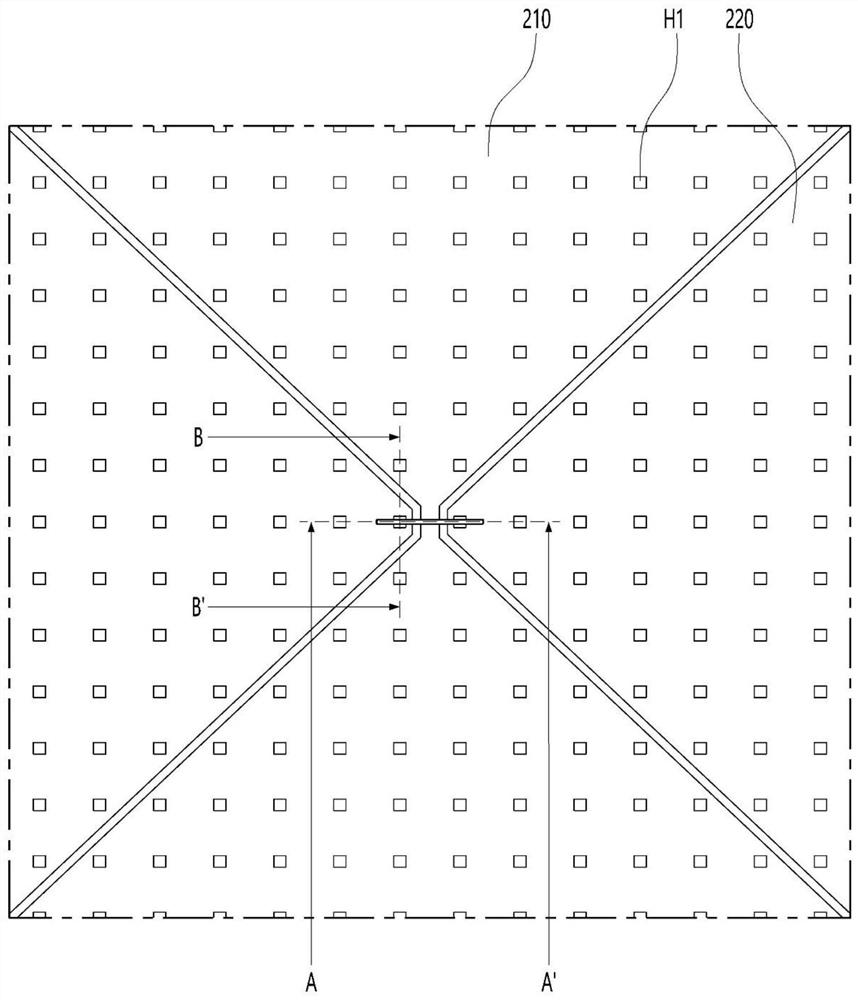

[0036] figure 1 and figure 2 Respectively, an assembled perspective view and an exploded perspective view of the touch sensor according to the present invention.

[0037] Such as figure 1 and figure 2 As shown in , the touch sensor according to the present invention may include a base layer 100 , an electrode layer 200 , an insulating layer 300 , a bridge member 500 , a passivation layer 400 and the like.

[0038] The base layer 100 is a base supporting the electrode layer 200 etc. combined thereon. The base layer 100 may generally be a base film. When the touch sensor is manufactured by a transfer method, the base layer 100 may be a separation layer or the like.

[0039] The base film is not limited if it has good transparency, mechanical strength and thermal stability. Specific examples of the base film may include thermoplastic resins, for example, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com