Staggered four-foot driving piezoelectric stepping linear motor

A linear motor, stepper technology, applied in piezoelectric/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Improve stability, maintain contact force, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the objectives, technical solutions and beneficial effects of the present invention clearer and clearer, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

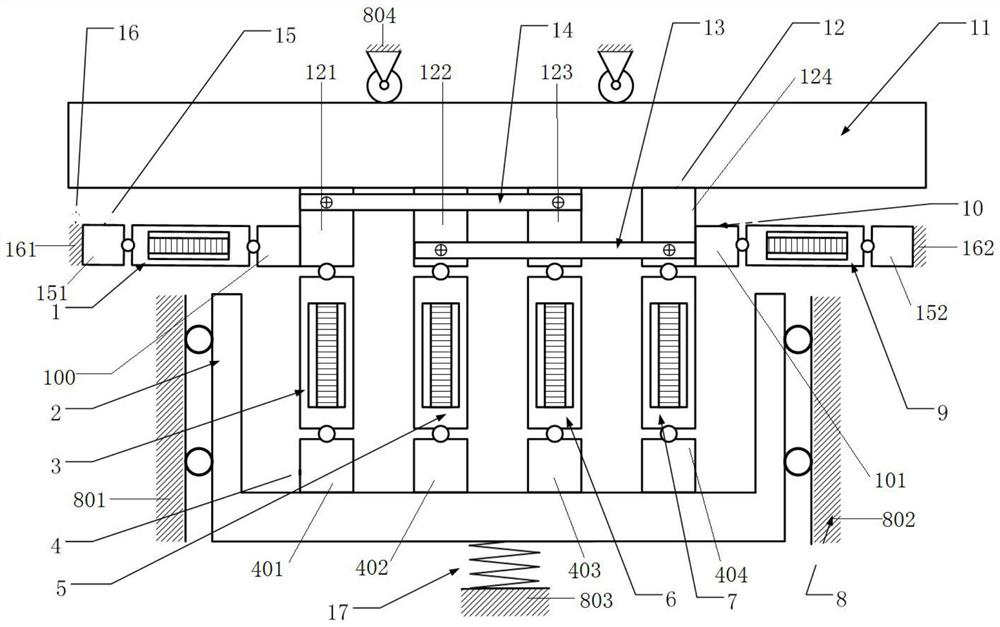

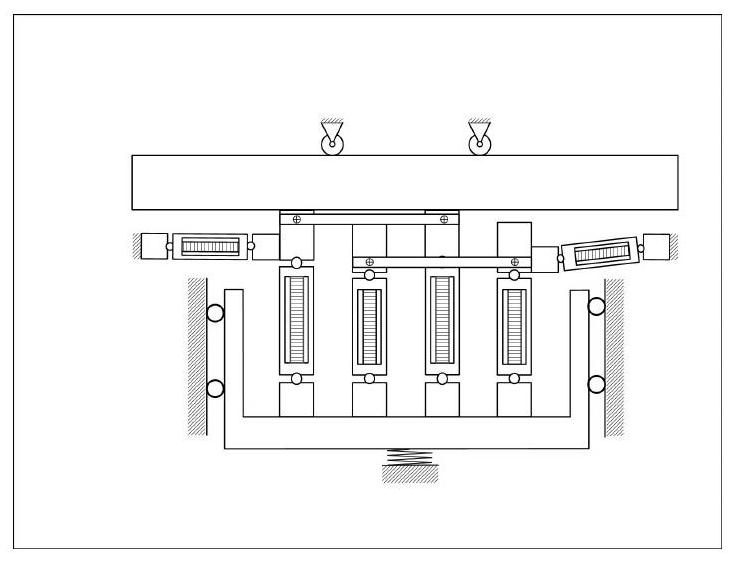

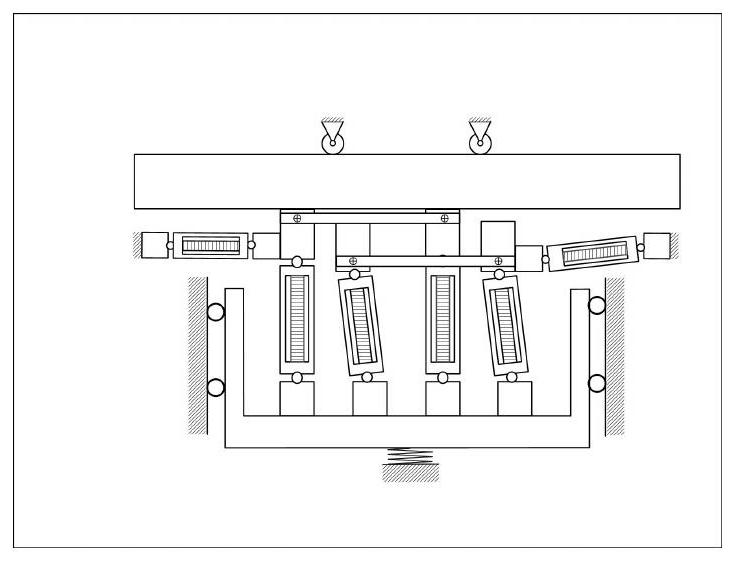

[0044] Such as figure 1 As shown, the interlaced quadruped driving piezoelectric stepping linear motor of the present invention has a specific structure including a first actuating rod 1, a guide seat 2, a third actuating rod 3, a vertical flexible hinge 4, and a fourth actuating rod 5 , the fifth actuator rod 6, the sixth actuator rod 7, the middle base 8, the second actuator rod 9, the horizontal clamp foot 10, the mover 11, the vertical clamp foot 12, the linkage rod II13, the linkage rod I14, horizontal flexible hinge 15, upper base 16, compression spring 17.

[0045] The vertical flexible hinge 4 includes a vertical flexible hinge I 401 , a vertical fl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap