Steering system with pivot bearing

A technology of steering system and pivot bearing, which is applied in the field of steering system, can solve the problems of limited load capacity of pivot bearing and damage of pivot bearing, and achieve the effects of increased load capacity, increased rated load, and simplified rolling elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

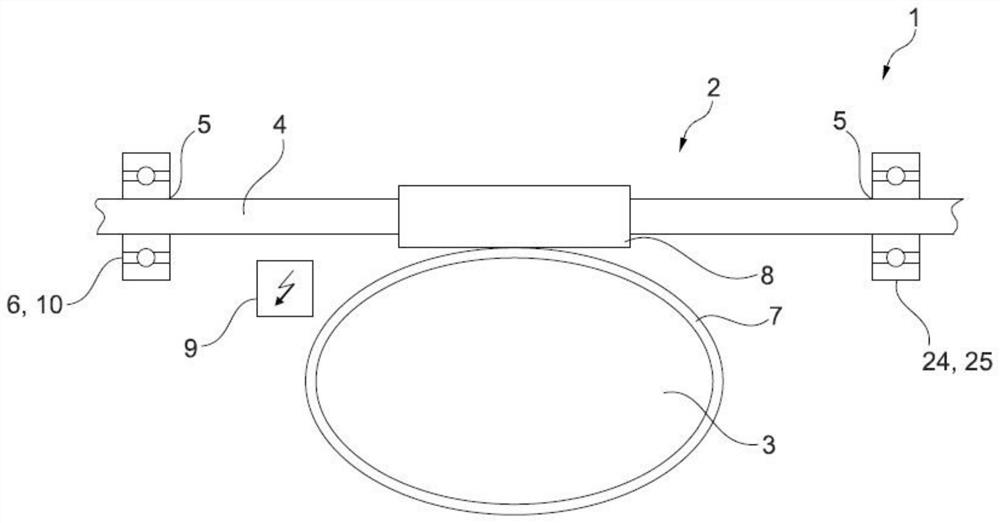

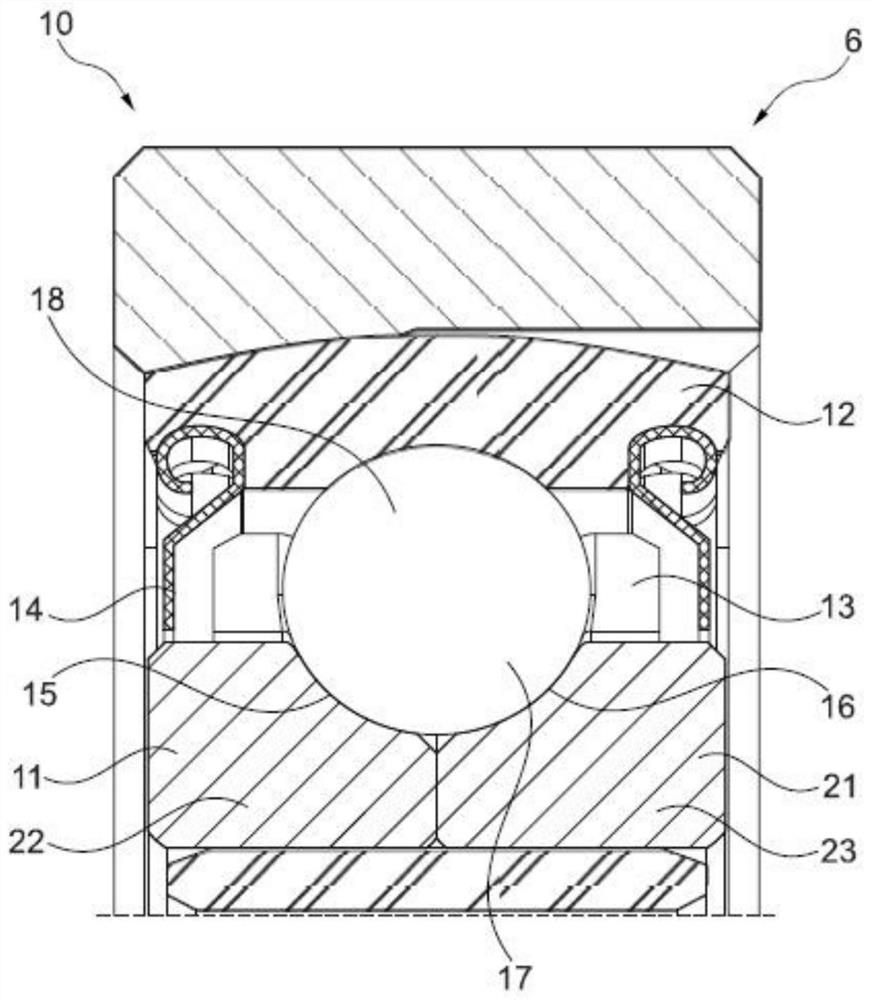

[0021] exist figure 1 An exemplary embodiment of a steering system 1 according to the invention with a pivot bearing 6 according to the invention is shown in . The steering system has a worm gear set 2 with which the steering torque is transmitted from a worm shaft 4 to a worm gear 3 . For this purpose, a toothing element 7 is formed on the worm wheel 3 , which meshes with a toothing part 8 of the worm shaft 4 . The worm shaft 4 is mounted rotatably at at least one bearing point 5 , preferably at least two bearing points 5 , in the housing of the worm gear set 2 . The steering system 1 is preferably designed as an electrically assisted steering system 1 . To this end, the steering system 1 includes an electric steering assistance system 9 with which the driver's steering force is supported for changing the steering angle. According to the invention, the worm shaft 5 is mounted on the drive side by means of a pivot bearing 6 . On the side facing away from the drive side, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap