Full-automatic stone ground cleaning, renovating, crystallizing and maintaining equipment and method

A fully automatic technology for floor cleaning, applied in cleaning equipment, manual floor scrubbing machines, metal processing equipment, etc., can solve problems such as inability to maintain stone floors, inability to clean stubborn stone stains, incomplete cleaning and maintenance, etc., to achieve improved stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

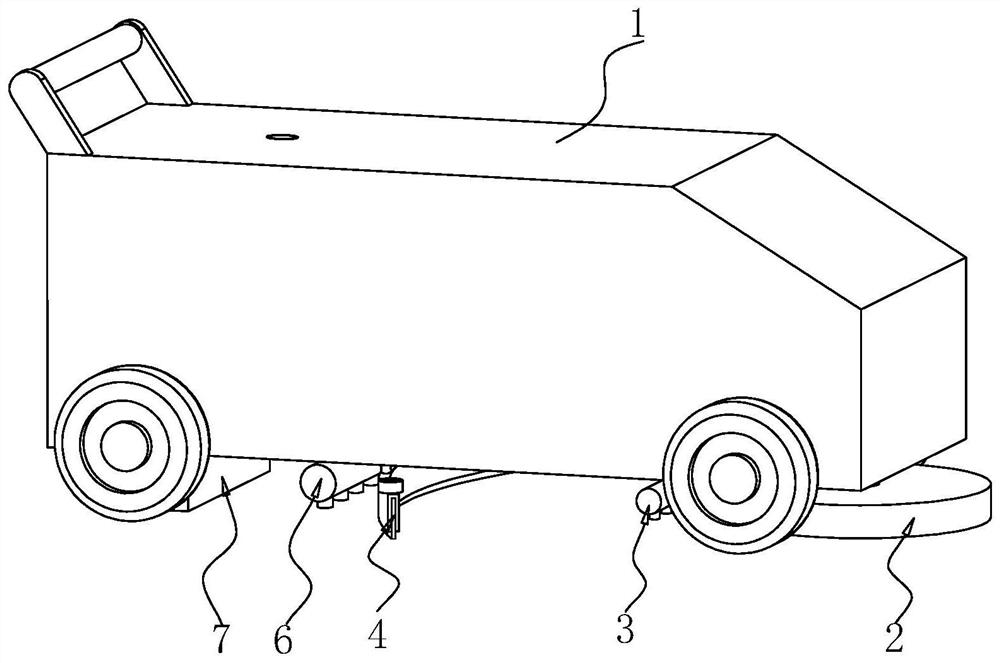

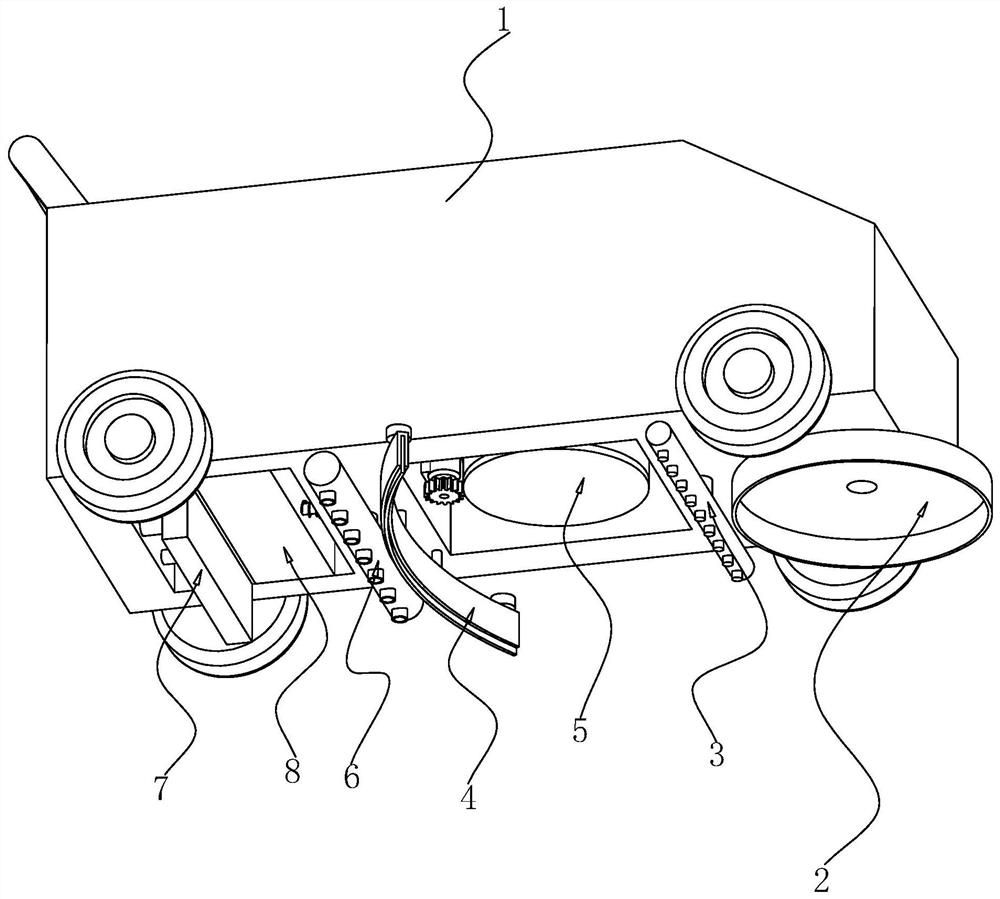

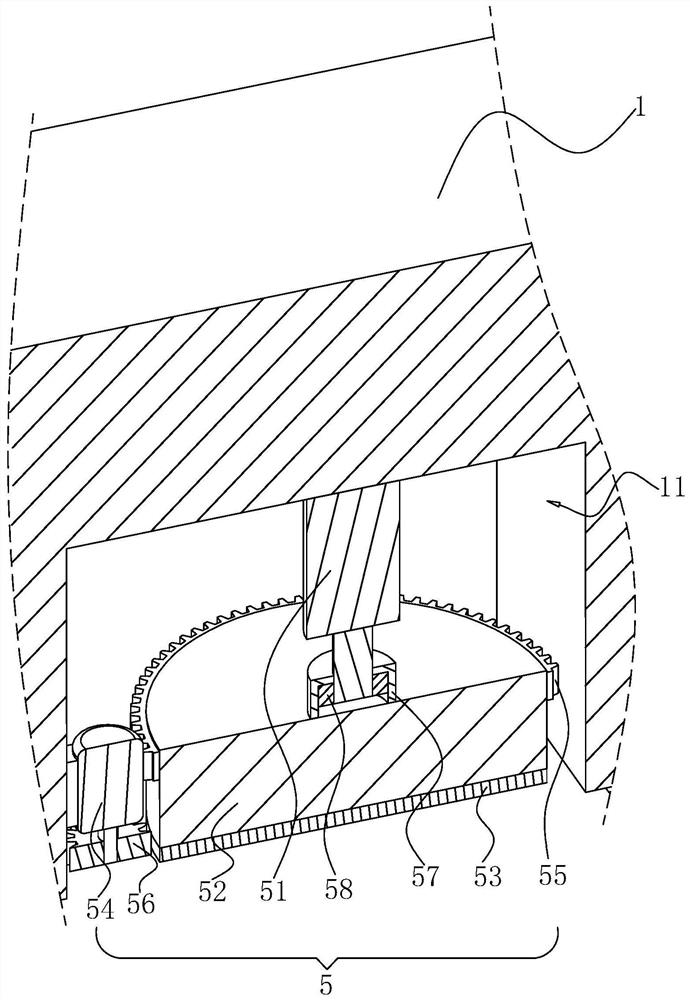

[0044] refer to figure 1 and figure 2, is the fully automatic stone floor cleaning, refurbishment, crystallization and maintenance equipment disclosed in the present invention, comprising a walking locomotive 1, a dust suction assembly 2 for cleaning and absorbing ground dust is arranged between the front end of the bottom of the walking locomotive 1 and the ground, and the dust suction assembly 2 A spray assembly 3 is provided on the side close to the end of the locomotive 1; a sewage collection assembly 4 is provided on the side of the spray assembly 3 far away from the dust collection assembly 2, and a sewage collection assembly 4 is provided between the spray assembly 3 and the sewage collection assembly 4. The cleaning assembly 5 for cleaning stubborn stains on the stone floor, the side of the sewage collection assembly 4 away from the cleaning assembly 5 is provided with a drying assembly 6 for drying the stone floor, and the side of the drying assembly 6 away from the ...

Embodiment 2

[0054] The present invention is further set as: a method for fully automatic stone floor cleaning, refurbishment, crystallization and maintenance, comprising the following steps:

[0055] S1, ground dust cleaning;

[0056] S2, ground spraying water;

[0057] S3, removal of stubborn stains on the ground. At this time, the cleaning cylinder 51 is adjusted. The cleaning cylinder 51 drives the cleaning plate 52 and the grinding disc 53 to move to the side close to the ground. When the grinding disc 53 abuts against the ground, start the cleaning motor 54. The output shaft of the cleaning motor 54 drives the cleaning gear 56 to rotate, and then realizes driving the grinding disc 53 to rotate;

[0058] S4, ground sewage cleaning;

[0059] S5, the ground is dry;

[0060] In step S4, the exhaust fan 62 is started, and the exhaust fan 62 quickly sucks the outside air into the air inlet pipe 61, flows to the connecting pipe 63, and is sprayed out by the nozzle 64.

[0061] S6. Groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com