Anti-crease automatic carton packaging machine

An automatic packaging machine and carton technology, applied in the direction of packaging machines, packaging, wrapping paper, etc., can solve the problem that the carton plastic film bag conveyor belt is difficult to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

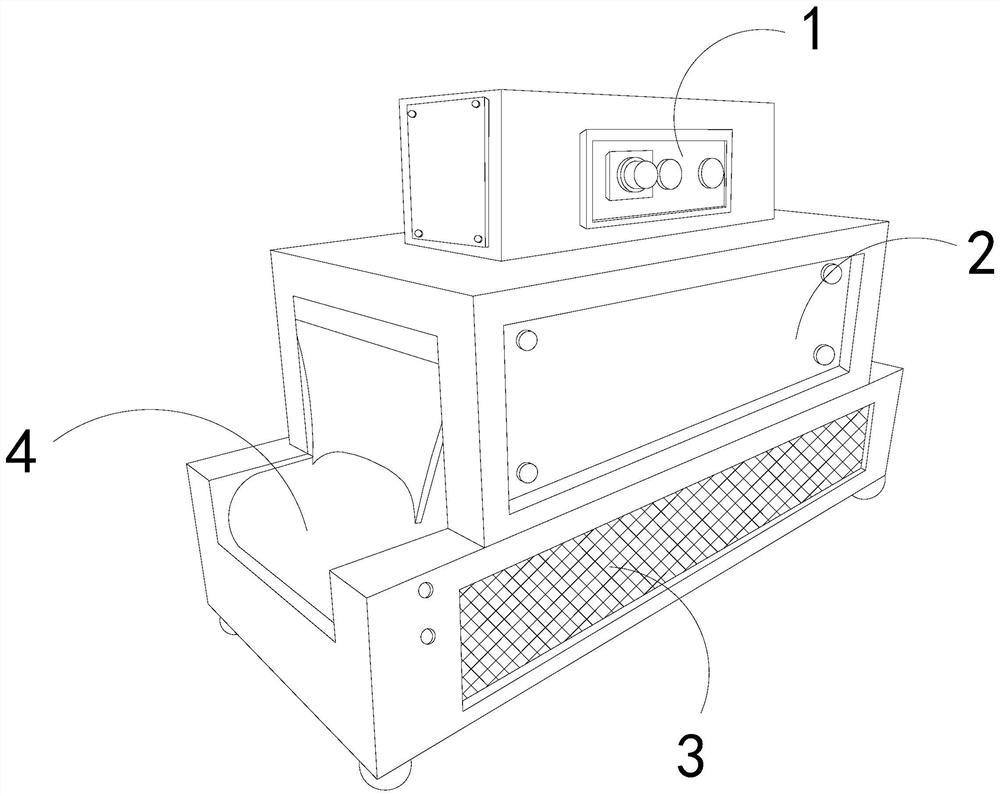

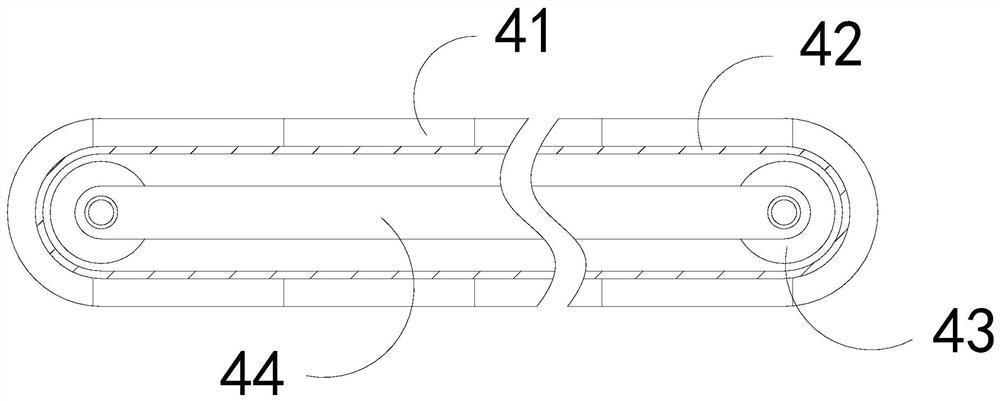

[0027] The present invention provides a crease-proof carton automatic packaging machine, which comprises a console 1, a heating chamber 2, a base 3, and a conveyor belt 4. The console 1 is embedded in the upper end of the heating chamber 2, and the heating The warehouse 2 is installed at the upper end of the base 3, and the conveyor belt 4 is movably engaged with the base 3; the conveyor belt 4 includes an upper contact plate 41, a linkage belt 42, a transmission roller 43, and a middle rod 44. The upper contact plate 41 It is embedded and fixed on the outer surface of the linkage belt 42 , the linkage belt 42 is movably engaged with the transmission roller 43 , and the intermediate connecting rod 44 is installed between the two transmission rollers 43 .

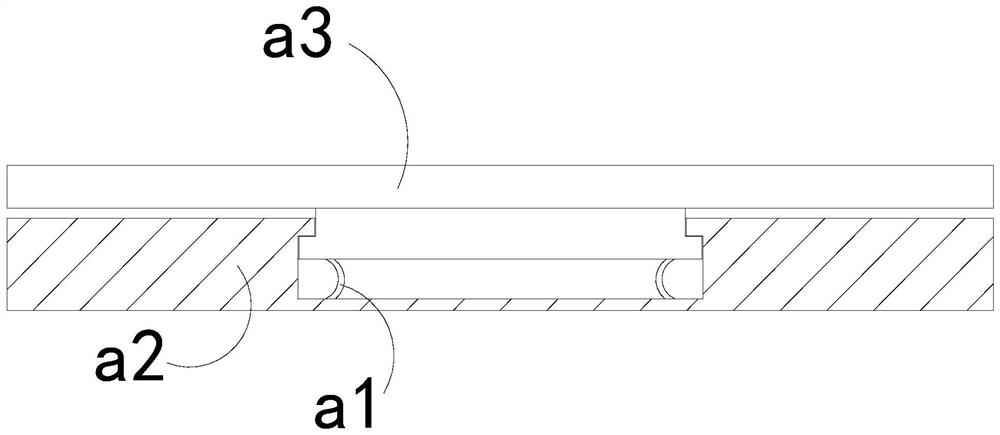

[0028] Wherein, the upper contact plate 41 includes an upper push piece a1, a plate body a2, and a contact plate a3. The upper push piece a1 is installed at the botto...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the stressed roller b2 includes an outer connecting plate b21, a telescopic rod b22, an outer pushing piece b23, and a middle solid block b24. The outer connecting plate b21 is embedded in the outer position of the telescopic rod b22. The block b24 is movable and engaged, and the outer push piece b23 is installed between the middle solid block b24 and the telescopic rod b22. There are four outer connecting plates b21, which are evenly distributed in a circular shape outside the middle solid block b24. Through the throwing force generated by the rotation of the mechanism, the outer connecting plate b21 can be extended outward along the middle solid block b24 under the cooperation of the telescopic rod b22.

[0036] Wherein, the outer connecting plate b21 includes a breathable plate c1, an inner connecting block c2, a plate c3, and a rebound frame c4, the breathable plate c1 is connected with the plate c3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com