Soluble bridge plug suitable for high-temperature well conditions

A technology for high-temperature wells and bridge plugs, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc. It can solve the problems that soluble bridge plugs cannot adapt to the production requirements of high-temperature shale gas wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

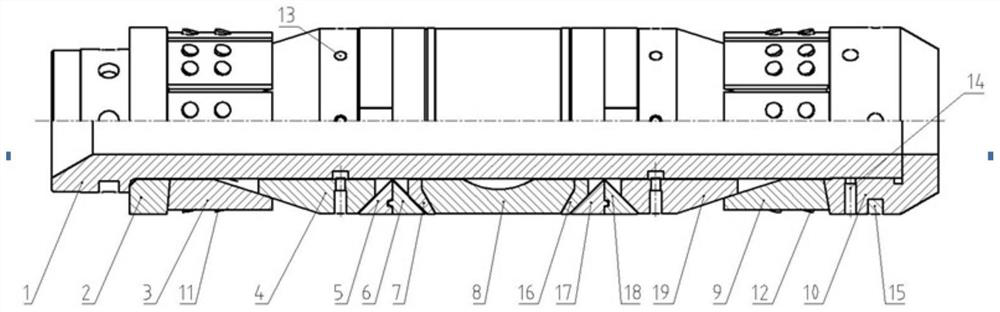

[0037] refer to figure 1 , a dissolvable bridge plug suitable for high-temperature well conditions provided by the present invention includes a center pipe 1, a spacer ring 2 is arranged at one end of the center pipe 1, and an anti-collision ring 10 is arranged at the other end, and the spacer ring 2 and the anti-collision ring 10 The central pipe 1 between the collision rings 10 is sequentially provided with upper slips 3, upper cones 4, upper female expansion rings 5, upper male expansion rings 6, upper rubber cylinders 8 seats 7, rubber cylinders 8, and lower rubber cylinders 8 seats, lower male expansion ring 17, lower female expansion ring 18, lower cone 19, lower slips 9; upper slips 3 and lower slips 9 are integral cylindrical slips, upper slips 3 The inner and outer surfaces of the upper and lower slips 9 are processed with stress cracks, the upper slips 3 and the lower slips 9 are provided with slip teeth; the central tube 1, the spacer ring 2, the anti-collision ring...

Embodiment 2

[0043] Based on Example 1, with reference to figure 1 , The anti-collision ring 10 of this embodiment is provided with anti-wear teeth 15, and the anti-wear teeth 15 are made of ceramics. In the present application, anti-wear teeth 15 are arranged on the anti-collision ring 10 to play the effect of anti-wear.

Embodiment 3

[0045] Based on Example 1, with reference to figure 1 In this embodiment, the stress cracks provided on the upper slip 3 and the lower slip 9 divide the upper slip 3 and the lower slip 9 evenly into 8 petals.

[0046] The upper slip 3 and the lower slip 9 of this application adopt an integral cylindrical structure, and 8 pairs of stress cracks are cut on the inner and outer surfaces, which can ensure that the slips are divided into 8 pieces when the stress is applied. When the force is applied, the integral cylindrical slip structure is more stable, which can protect the slips from being dissolved and damaged by the liquid in the well under high temperature conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com