Lamp strip end cover assembly and LED lamp strip structure

A technology for LED light strips and end cap components, which is applied to the components of lighting devices, semiconductor devices of light-emitting elements, and damage prevention measures for lighting devices, and can solve the problem of high manufacturing process requirements and the connection between end cap components and light strips Poor electrical connection, poor contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

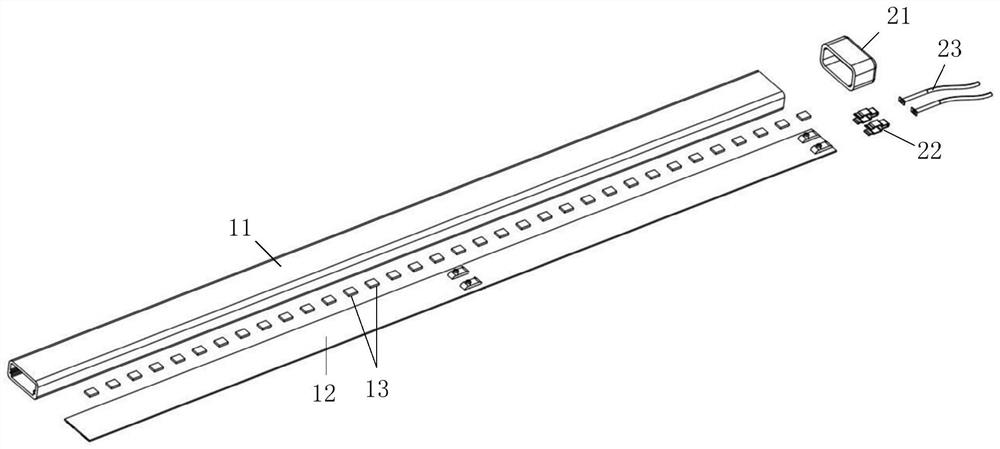

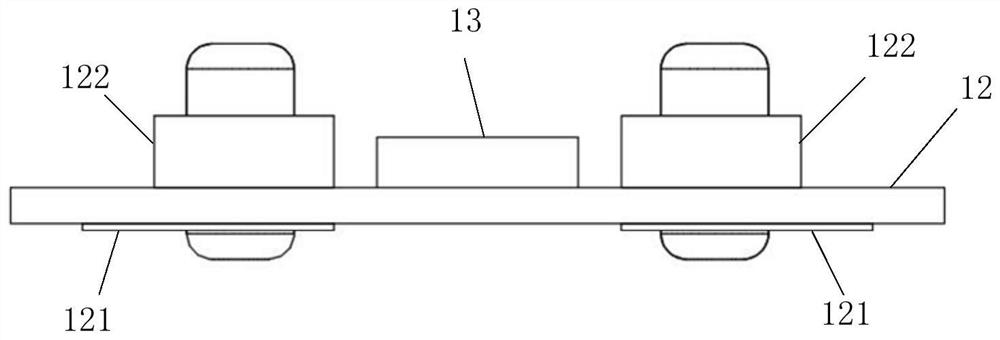

[0039] see figure 1 , the present invention provides an LED light strip structure provided by the present invention, including a light strip and an end cover assembly, the light strip includes a housing 11, a substrate 12 and an LED light source 13, and the end cover assembly includes an end cover 21, a shrapnel 22 and wire 23.

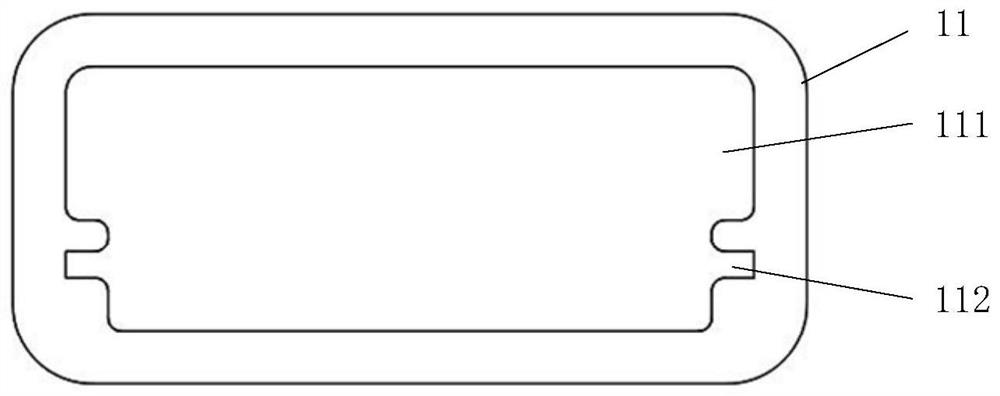

[0040] figure 2 It is a sectional view of the shell cut along the direction perpendicular to its length. see figure 2 , the housing 11 is a tubular structure, and is provided with a slot 112 for placing the substrate 12 and a hollow cavity 111 for accommodating the light source 13 . Preferably, the housing 11 is made of flexible light-transmitting insulating material, and the substrate 12 is a soft substrate made of aluminum. The housing 11 is provided with a slot 112 for clamping the substrate 12 , and when the light strip is assembled, the substrate 12 is clamped into the slot 112 . Wherein, the locking groove 112 communicates with the hollow...

Embodiment 1

[0057] Embodiment 1 has a good effect on the bending method in one case, that is, if the light strip is bent into a ring shape, the figure 2 The upper shell and the lower shell are used as the outer edge and the inner edge of the annular structure respectively, and the left shell and the right shell are used as the bending method of the side. However, if the bending direction is changed by 90°, that is, when the left shell and the right shell are respectively used as the outer edge and inner edge of the ring structure, and the upper shell and the lower shell are used as the sides of the bending method, it may not be possible to achieve purpose of design. Therefore, in this embodiment, on the basis of the first embodiment, both the double-sided conductive member 122 and the elastic piece 22 are rotated by 90°, so as to match different bending environments of the light strip. The parts not introduced in this embodiment are consistent with the first embodiment.

[0058] see ...

Embodiment 3

[0068] In order to optimize the structure of the end caps in Embodiment 1 and Embodiment 2, and achieve better contact between the end cap and the light strip, this embodiment is further optimized. For the sake of simplicity, only the improvement of the solution in the first embodiment is shown, and the same improvement can also be applied to the solution in the second embodiment.

[0069] see Figure 9 , an LED light strip structure provided by the present invention includes a light strip and an end cover assembly, the light strip includes a housing 11, a substrate 12 and an LED light source 13, and the end cover assembly includes an end cover 21, an elastic piece 22 and a wire 23 .

[0070] Different from Embodiment 1, the end cover assembly of this embodiment further includes a spring 24, so that the elastic piece 22 can move a short distance in the inner casing 212 of the end cover 21, or the elastic piece 22 has a certain swing range. During this moving or swinging proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com