Mechanical water meter convenient to assemble and rapid assembling method

A water meter and mechanical technology, which is applied in the field of water meter production equipment, can solve the problems that mechanical water meters cannot continue to be installed and used, are unfavorable for actual use, and cannot be quickly assembled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

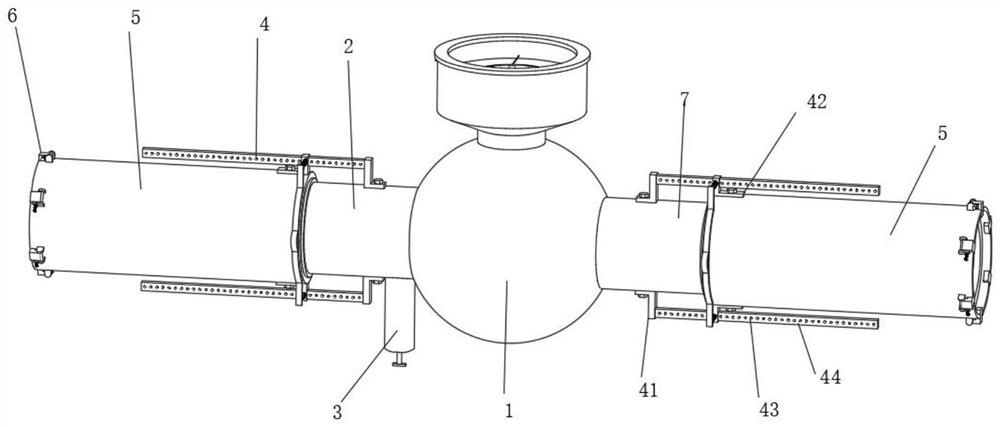

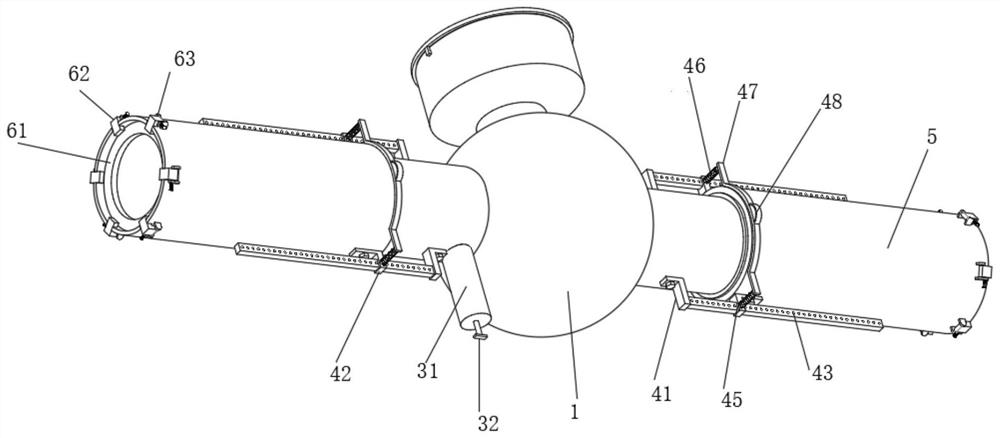

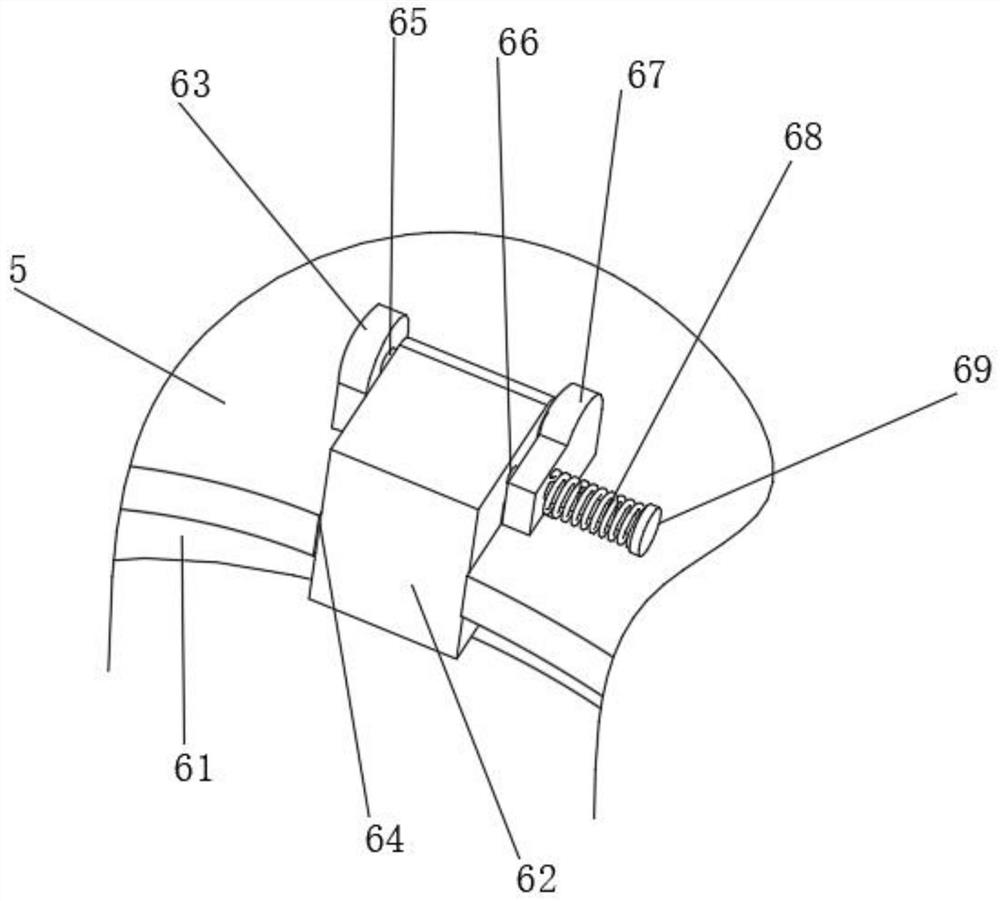

[0039] like figure 1 , 2, 4, and 7, a mechanical water meter that is easy to assemble includes a mechanical water meter body 1, the left and right ends of the mechanical water meter body 1 are respectively fixedly connected with a first connecting pipe 2 and a second connecting pipe 7, the first connecting pipe 2 It is connected with a pressure regulating structure 3 for water pressure regulation. The pressure regulating structure 3 includes a sleeve 31, a T-shaped plate 32, a piston 33, a first spring 34 and a sliding hole 35. The bottom of the sleeve 31 is provided with a sliding hole 35. The cylinder 31 is fitted and slidably connected with a T-shaped plate 32 through the sliding hole 35, and the inner end of the T-shaped plate 32 is fixedly connected with a piston 33 which is fitted and slidably connected with the inner wall of the sleeve 31, and the bottom of the piston 33 and the inner bottom of the sleeve 31 The first spring 34 is fixedly connected between them, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com