Hardware product clamping auxiliary punching equipment

A technology of punching equipment and products, applied in metal processing equipment, drilling/drilling equipment, clamping and other directions, can solve the problems of pressing the drill bit laboriously, hardware products cannot stop moving instantaneously, etc., to avoid position deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

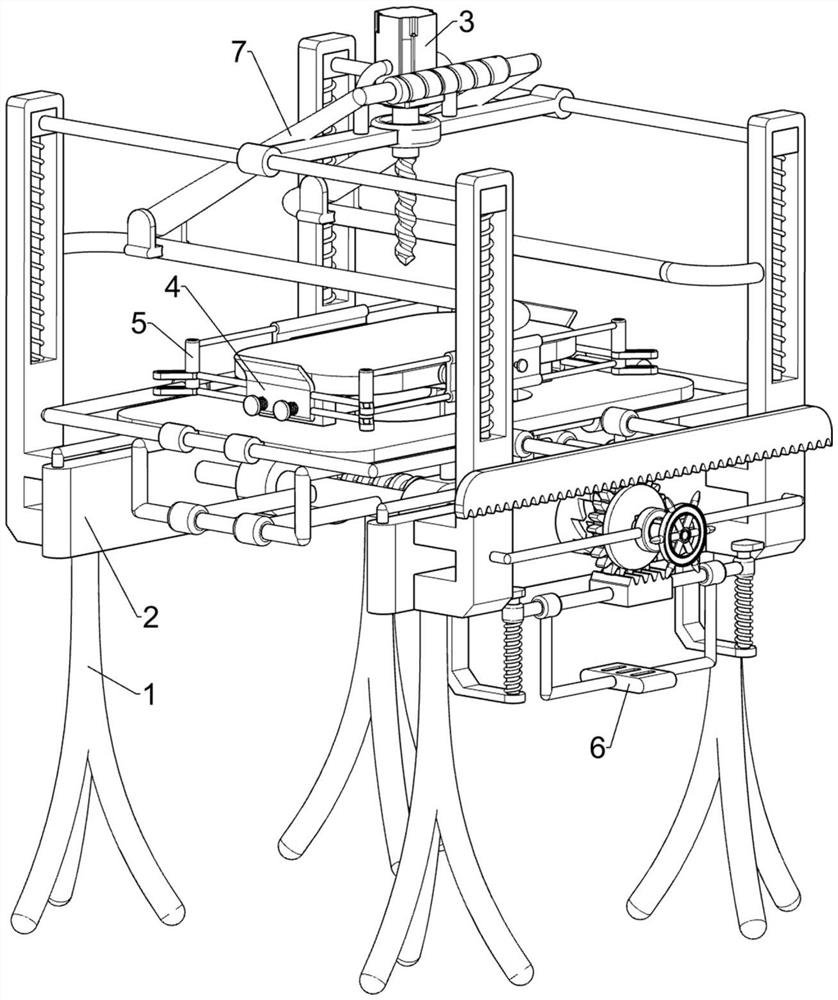

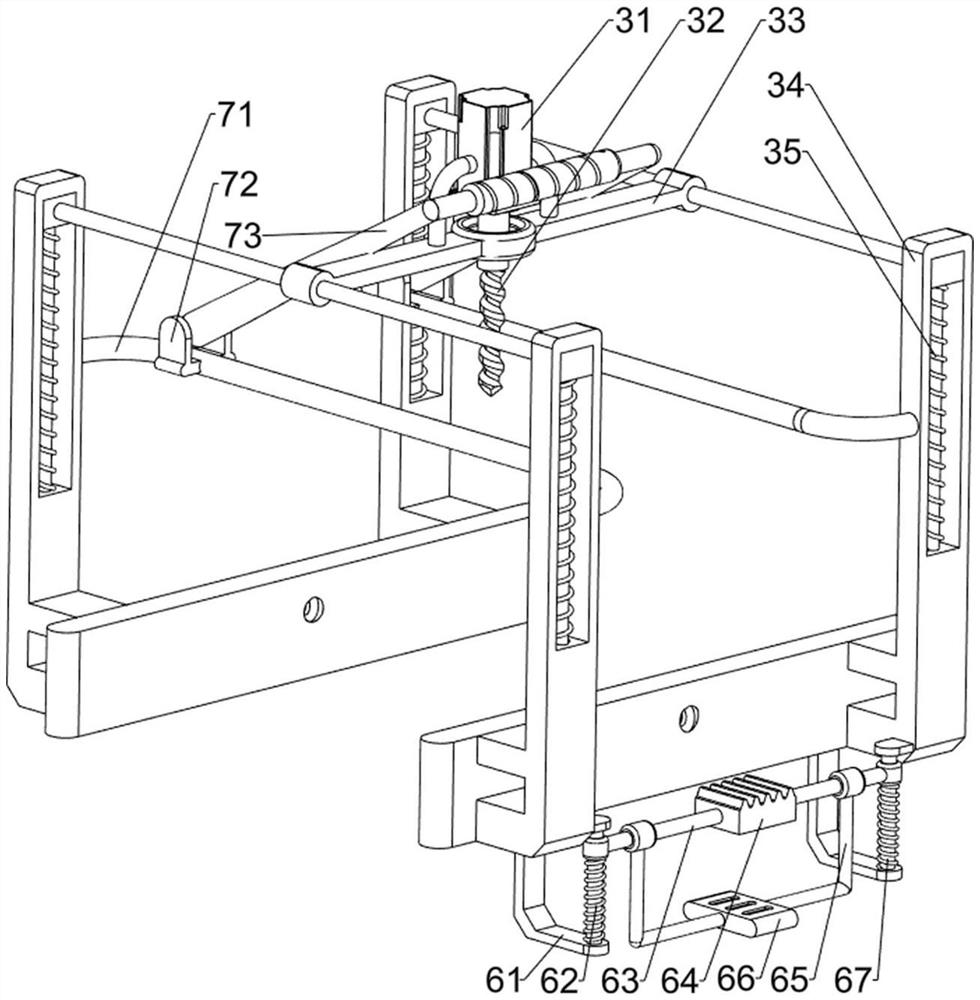

[0024] A punching device assisted by clamping of hardware products, such as figure 1 , figure 2 and image 3 As shown, it includes a supporting foot 1, a moving mechanism 2 and a punching mechanism 3. The supporting feet 1 are symmetrically arranged on the front and rear sides on the ground, and the moving mechanism 2 is arranged between the upper parts of the supporting feet 1. Punch mechanism3.

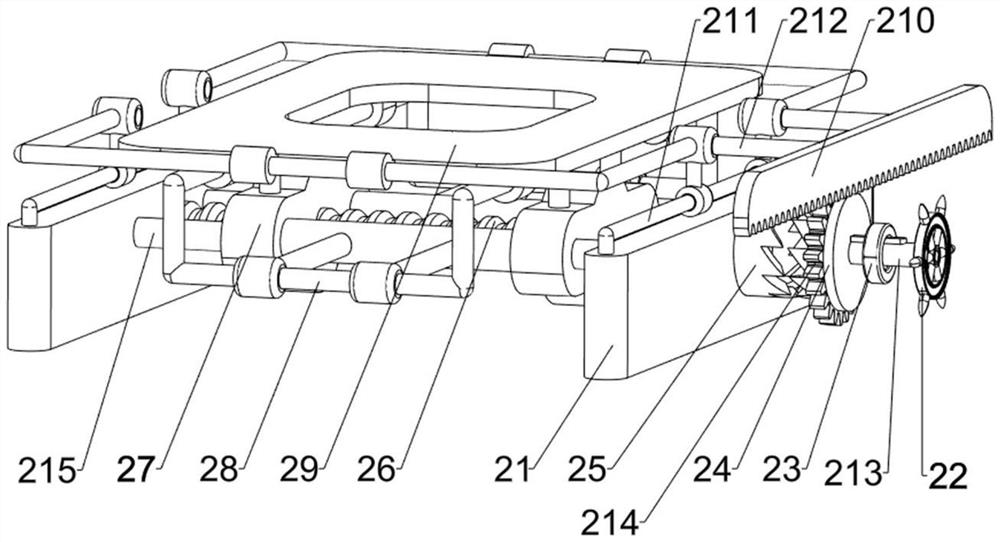

[0025] Moving mechanism 2 comprises base 21, hand wheel 22, supporting shaft frame 23, clutch block 24, transmission block 25, screw mandrel 26, position-limiting seat 27, first sliding seat 28, placing platform 29, rack 210, the first Two sliding seats 211 and a connecting frame 212, a base 21 is connected between the support feet 1 on the front and rear sides, and a support shaft frame 23 is connected between the left and right sides of the front side base 21, and the support shaft frame 23 is internally rotatable and The rotating shaft 213 is slidingly connected, the front si...

Embodiment 2

[0029] On the basis of Example 1, such as figure 1 , image 3 and Figure 4 Shown, also include lateral clamping assembly 4, lateral clamping assembly 4 includes stand 41, second guide bar 42, second spring 43, arc plate 44, long rod 45 and groove block 46, place platform 29 The left and right sides of the upper part are all connected with a stand 41, and the outside of the stand 41 is connected with a second guide rod 42 symmetrically before and after, and an arc-shaped plate 44 is slidably connected between the second guide rod 42, and the arc-shaped plate 44 is connected with the second guide rod 42. A second spring 43 is connected between the outer sides of the guide rods 42, and the second spring 43 is sleeved on the second guide rod 42. The front and rear sides of the arc plate 44 are connected with long rods 45 symmetrically up and down. Between all are connected with groove block 46.

[0030] Also includes a longitudinal clamping assembly 5, the longitudinal clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com