A welding method of an ultrasonic welding machine

A welding method and ultrasonic technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of prolonged cylinder action time, large stroke distance, and crushed parts to be welded, so as to improve welding efficiency and ensure welding. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

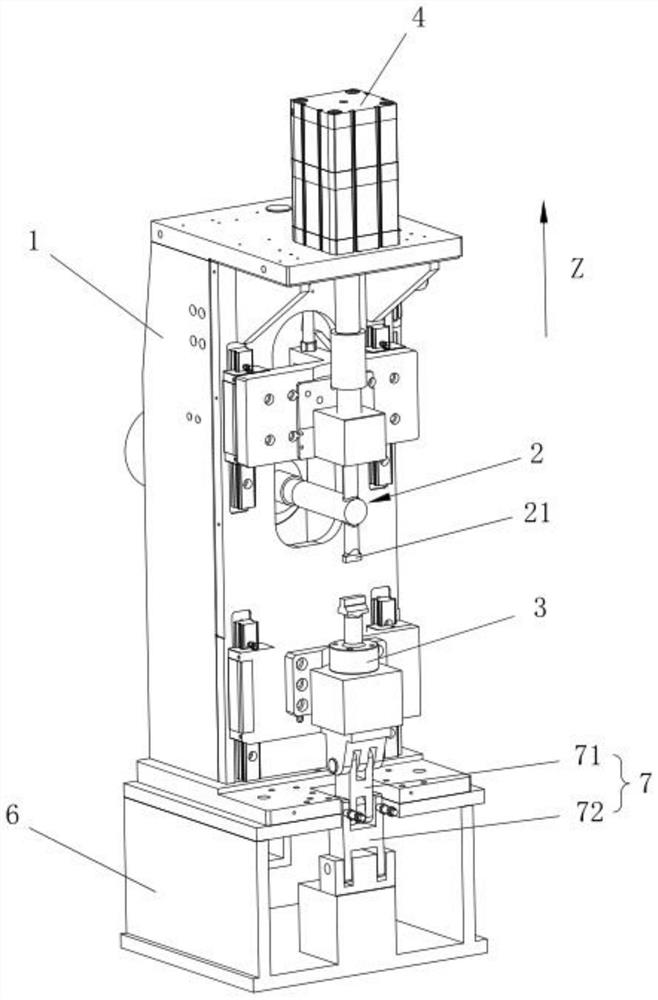

[0039] This embodiment provides an ultrasonic welding machine, such as figure 1 As shown, the ultrasonic welding machine includes a frame 1, a triple group 2, a first drive assembly, a welding seat 3 and a second drive assembly, the triple group 2 includes a welding head 21, and the triple group 2 is movably arranged on the frame 1, and The triplet 2 can move along the Z direction; the first drive assembly is connected to the triplet 2 through a transmission to drive the triplet 2 to move along the Z direction, and the first drive assembly can drive the triplet 2 to move to the preset position and the first working position; The welding seat 3 is movably arranged on the frame 1, and the welding seat 3 can move in the Z direction. The second driving component is connected with the welding seat 3 to drive the welding seat 3 to move in the Z direction, and the second driving component can drive the welding seat. 3 Move to the second working position; when the first drive assembly...

Embodiment 2

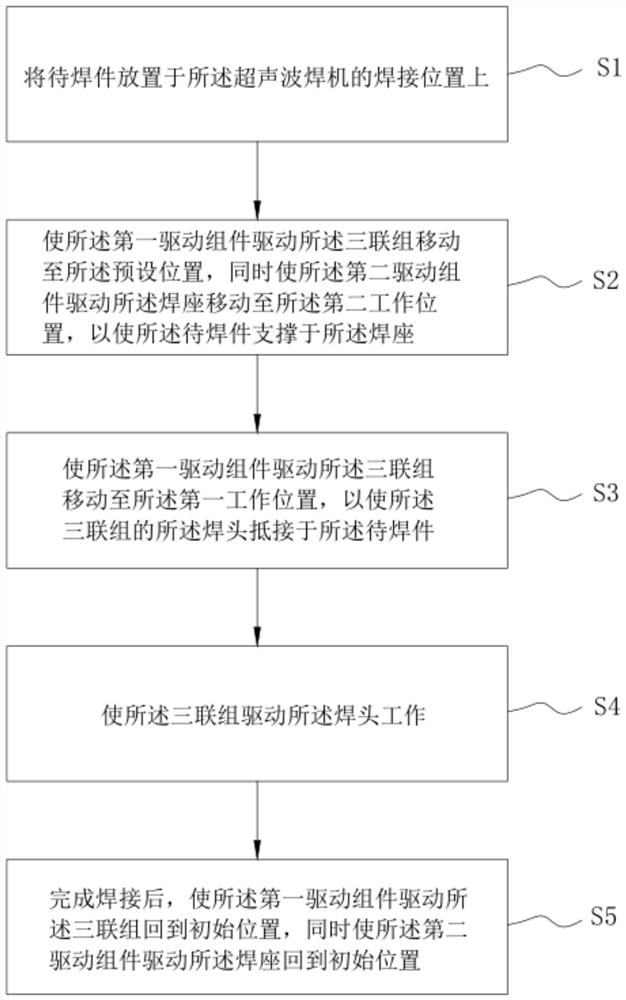

[0047] This embodiment provides a welding method for an ultrasonic welding machine, and the welding method uses the ultrasonic welding machine in the first embodiment to perform welding operations, such as figure 2 As shown, the welding method includes the steps:

[0048] S1. Place the parts to be welded on the welding position of the ultrasonic welding machine;

[0049] S2. Make the first drive assembly drive the triplet 2 to move to a preset position, and while driving the triplet 2 to move, make the second drive assembly drive the welding seat 3 to move to the second working position, so that the workpiece to be welded is supported on the welding seat 3;

[0050] S3, make the first drive assembly drive the triple group 2 to move to the first working position, so that the welding head 21 of the triple group 2 is in contact with the workpiece to be welded;

[0051] S4, make the triple group 2 drive the welding head 21 to work, so that the welding head 21 performs the weldi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap