Electrical camshaft adjuster and method for producing camshaft adjuster

A camshaft adjuster, camshaft adjustment technology, applied in camshaft drive, valve details, machine/engine, etc., can solve problems such as high consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

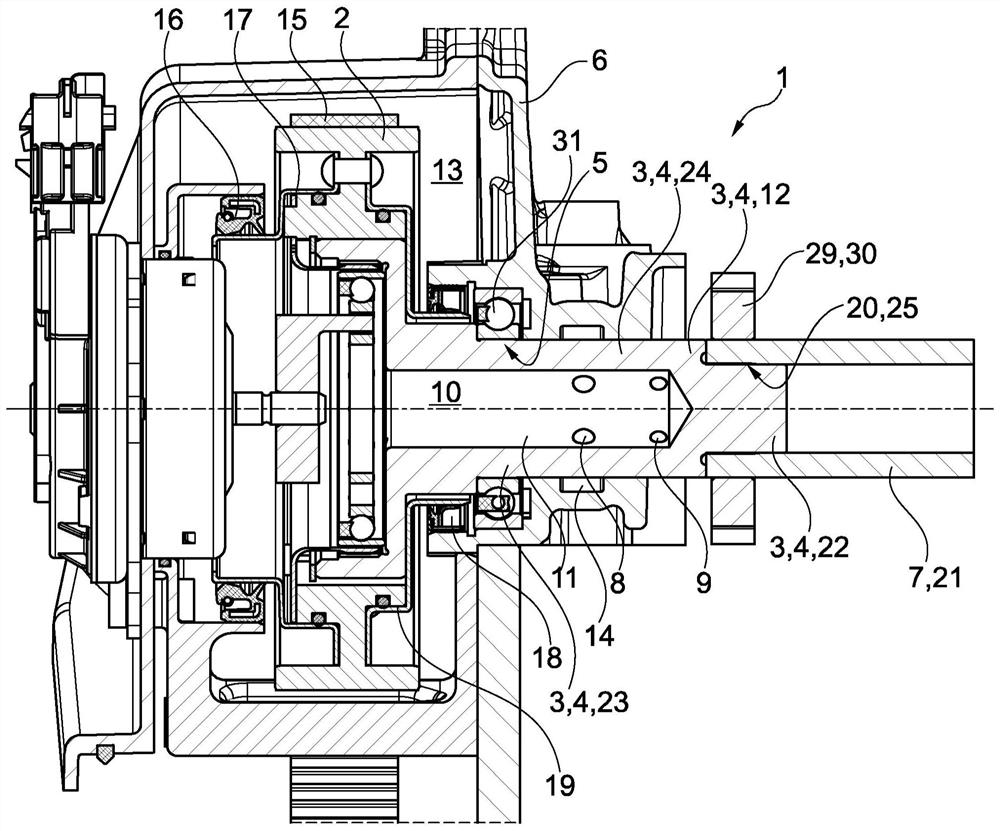

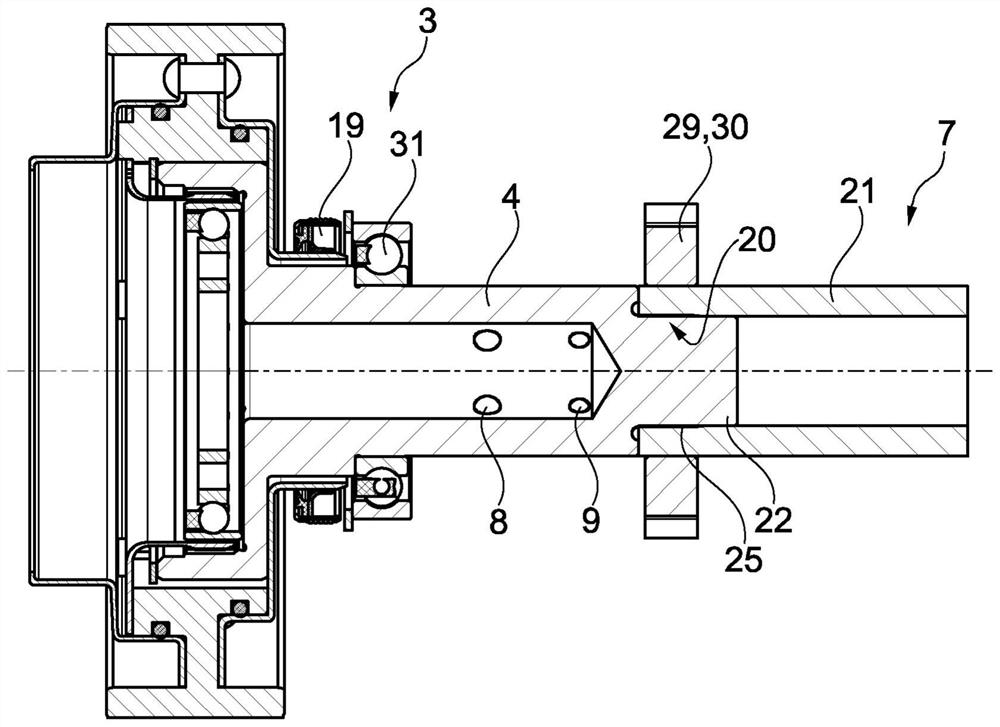

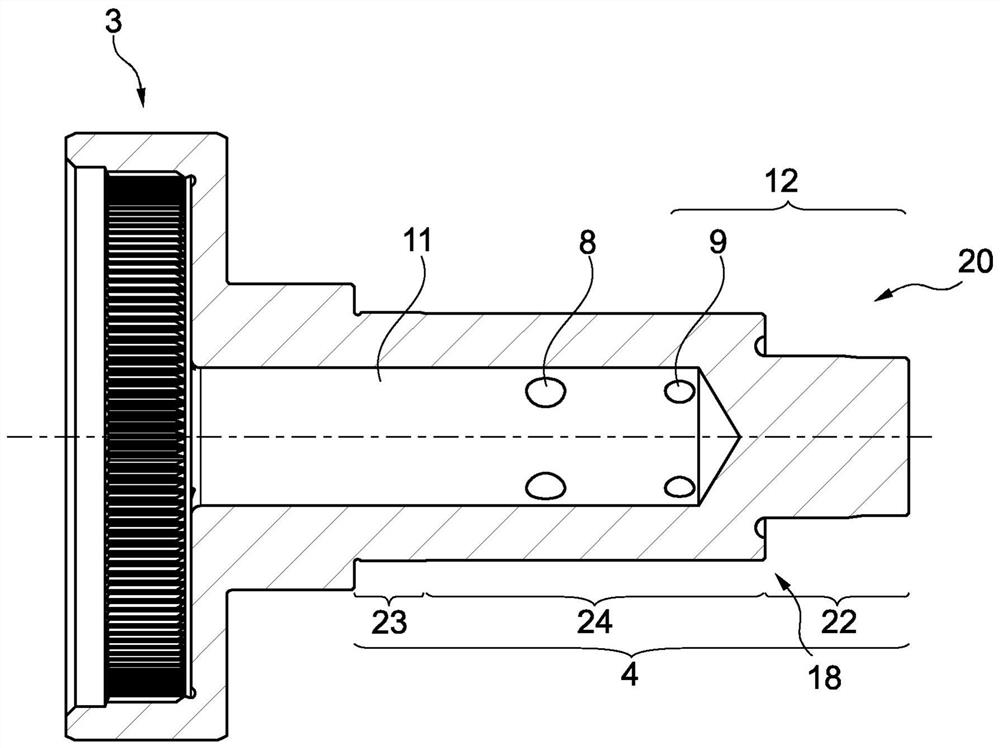

[0040] figure 1 and figure 2 An electrical camshaft adjuster 1 according to the invention for a drive train of a motor vehicle is shown. The camshaft adjuster 1 has a drive wheel 2 . The drive wheel 2 can be driven by a circulating traction mechanism. The drive wheel 2 is connected to a not shown crankshaft. The camshaft adjuster 1 has a driven ring gear 3 arranged coaxially to the drive wheel 2 . The driven ring gear 3 can rotate relative to the driving wheel 2 through the electric motor. The driven ring gear 3 has an extension 4 extending it axially. Bearing points 5 for radial support on the housing 6 are formed on the extension 4 . The extension 4 is prepared for fastening at the camshaft 7 . Preferably, the extension 4 has a higher material strength than the camshaft 7 .

[0041] According to the invention, the extension 4 has at least one at least partially radially oriented oil inlet channel 8 and at least one at least partially radially oriented oil outlet cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com