High-temperature-resistant modified diaphragm and preparation method thereof

A high-temperature-resistant and high-temperature-resistant resin technology, which is applied in the field of high-temperature-resistant modified diaphragms and their preparation, can solve the problems of poor secondary coating permeability and poor heat resistance of the flat diaphragm, and achieve good industrialization Application prospects, shortening of operation time, effect of increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, a high-temperature-resistant modified diaphragm, the preparation method includes the following steps:

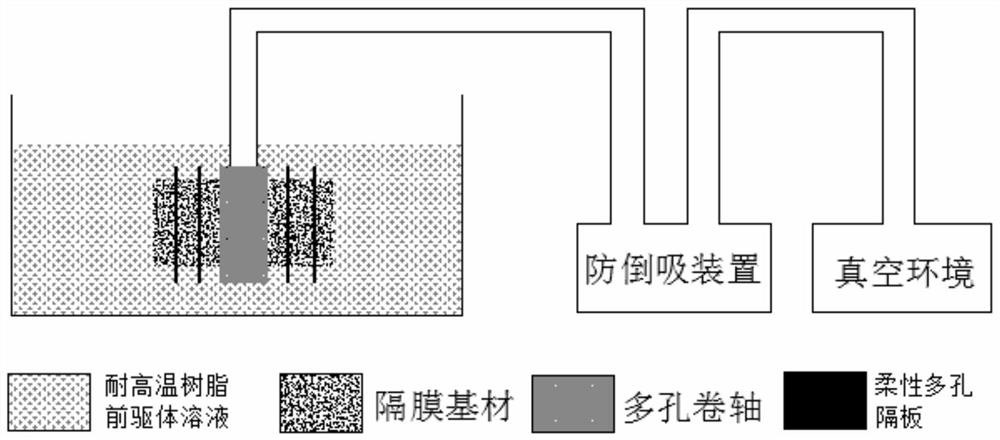

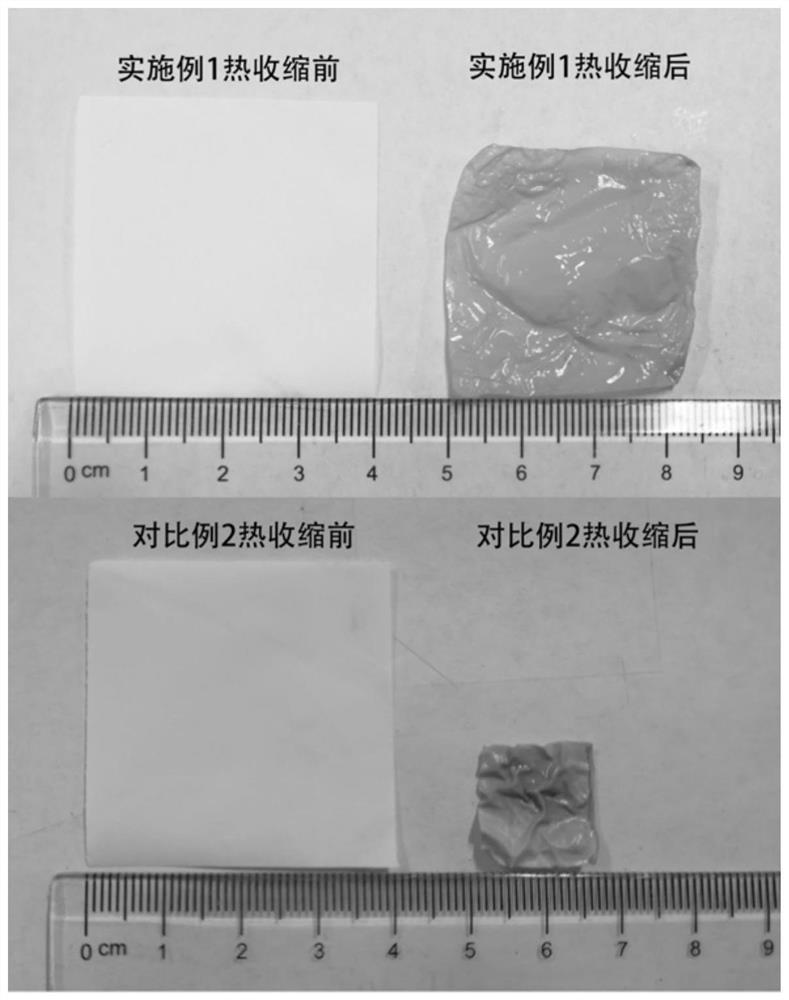

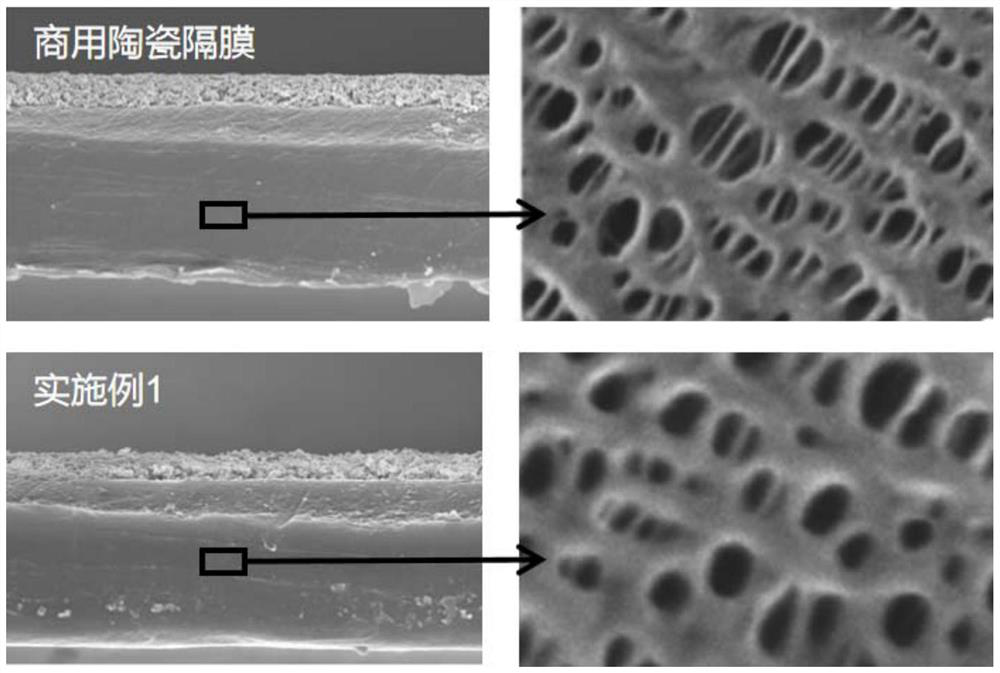

[0035] 4 parts of bisphenol A epoxy resin, 0.1 part of m-xylylenediamine, 0.01 part of phenolic resin and 95 parts of ethanol are fully mixed to prepare a high temperature resistant resin precursor solution. A flexible porous separator is sandwiched between every 8 mm thickness of the polyethylene (PE) porous ceramic base film with a double-sided ceramic coating thickness of 4 μm and a substrate thickness of 12 μm, so that there is a gap between the layers when it is rolled up. There are gaps. After the solution is fully dissolved and mixed, soak the entire roll of ceramic base membrane in the solution, and let it stand for 3 hours in a vacuum environment with a relative vacuum of -0.1MPa, so that the solution can better enter the surface and pores of the porous ceramic base membrane internal. Afterwards, the entire roll of diaphragm was taken ou...

Embodiment 2

[0038] The difference between Example 2 and Example 1 is: 7 parts of bisphenol A epoxy resin, 2 parts of dicyandiamide, 0.8 parts of 1-carbamoyl imidazole and 91 parts of ethanol are fully mixed to make a high temperature resistant resin precursor solution. A flexible porous separator is sandwiched between every 8mm of the polyethylene (PE) porous ceramic base film with a double-sided ceramic coating thickness of 4um and a substrate thickness of 12um, so that there is a gap between the layers when it is rolled up. void. After the solution is fully dissolved and mixed, soak the entire roll of ceramic base membrane in the solution, and let it stand for 3 hours in a vacuum environment with a relative vacuum of -0.07MPa, so that the solution can better enter the surface and pores of the porous ceramic base membrane internal. Afterwards, the entire roll of diaphragm was taken out from the vacuum environment after breaking the vacuum, and dried in a blast oven at 50°C for 36 hours...

Embodiment 3

[0040] The difference between embodiment 3 and embodiment 1 is: 4 parts of bisphenol F type epoxy resin, 1 part of N-aminoethylpiperazine, 0.5 part of 2,4,6-three (dimethylaminomethyl) phenol It is fully mixed with 94.5 parts of ethanol to make a high temperature resistant resin precursor solution. A flexible porous separator is sandwiched between every 4mm of the polyethylene (PE) porous ceramic base film with a double-sided ceramic coating thickness of 4um and a substrate thickness of 12um, so that there is a gap between the layers when it is rolled up. void. After the solution is fully dissolved and mixed, soak the entire roll of ceramic base membrane in the solution, and let it stand for 3 hours in a vacuum environment with a relative vacuum of -0.1MPa, so that the solution can better enter the surface and pores of the porous ceramic base membrane internal. Afterwards, the entire roll of diaphragm was taken out from the vacuum environment after breaking the vacuum, and dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com