Rotatable pluggable terminal block

A terminal block and male head technology, which is applied in the field of rotatable plug-in terminal blocks, can solve the problems that the terminal blocks are not easy to install, difficult to disassemble and maintain, and achieve the effects of avoiding dust and moisture, facilitating maintenance, and ensuring firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

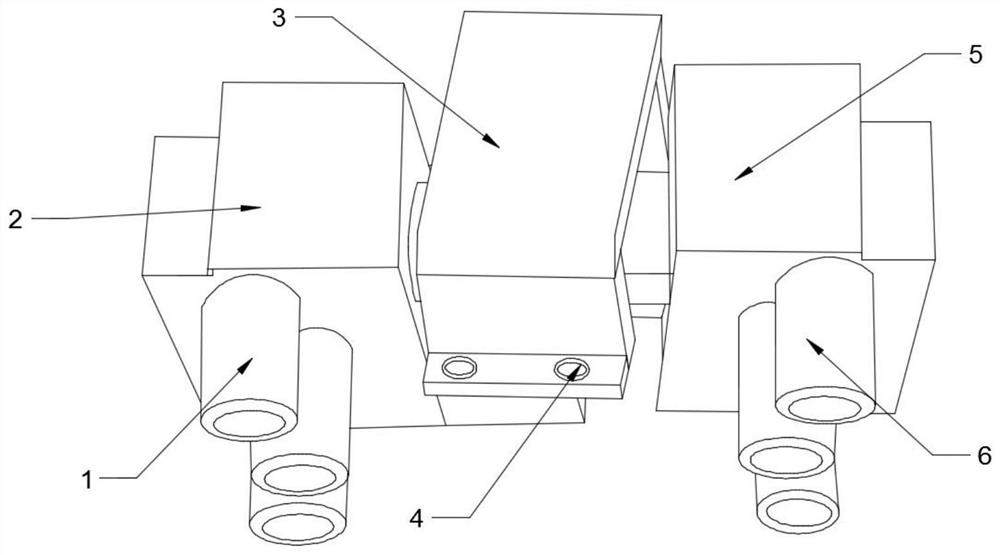

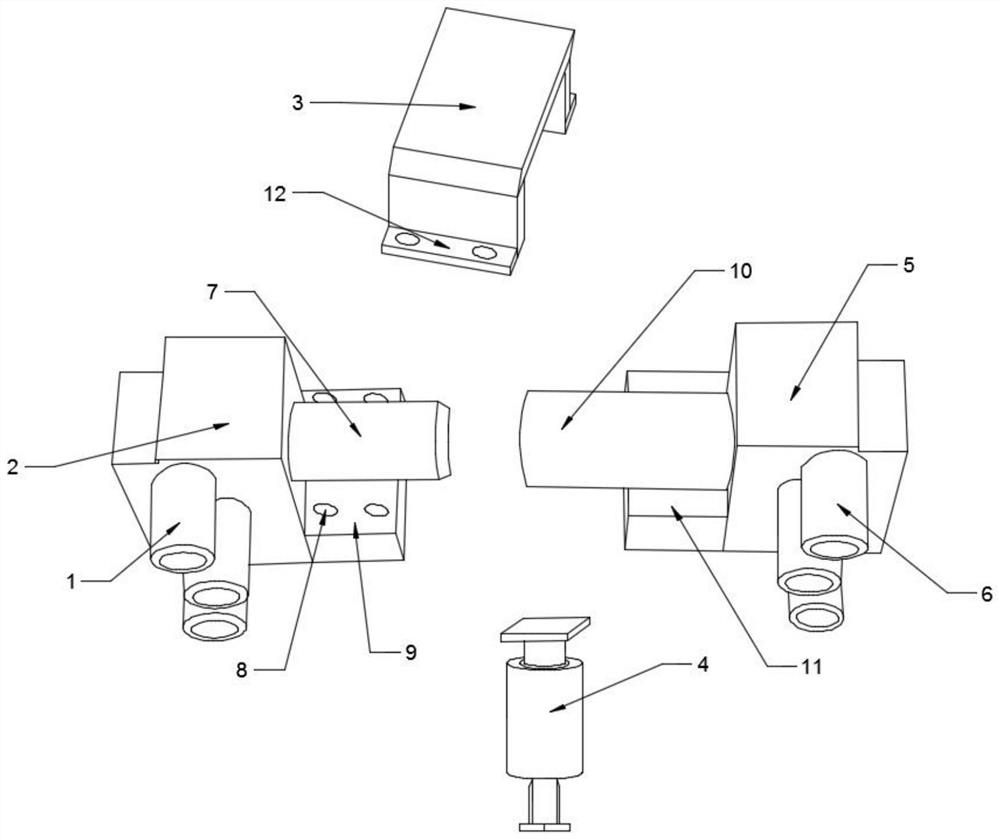

[0021] see figure 1 with figure 2 , in Embodiment 1 of the present invention, a rotatable plug-in terminal block, which includes: a male head 2, a female head 5, and a cover 3; one end of the male head 2 is provided with a terminal 7 and a mounting plate 9, and the installation A mounting hole 8 is opened on the plate 9; a wiring barrel 10 and a cover plate 11 are installed at one end of the female connector 5; when the male connector 2 and the female connector 5 are assembled to form a complete rotatable plug-in terminal block, the male connector 2 After the terminal 7 provided at one end is rotated and inserted into the terminal barrel 10 installed at one end of the female connector 5, the cover 3 is provided to cover the connection position between the terminal post 7 and the terminal barrel 10; the cover 3 is installed and fixed by the locking assembly 4 Inside the mounting hole 8 provided on the mounting plate 9;

[0022] The provided cover 3 can seal and shield the co...

Embodiment 2

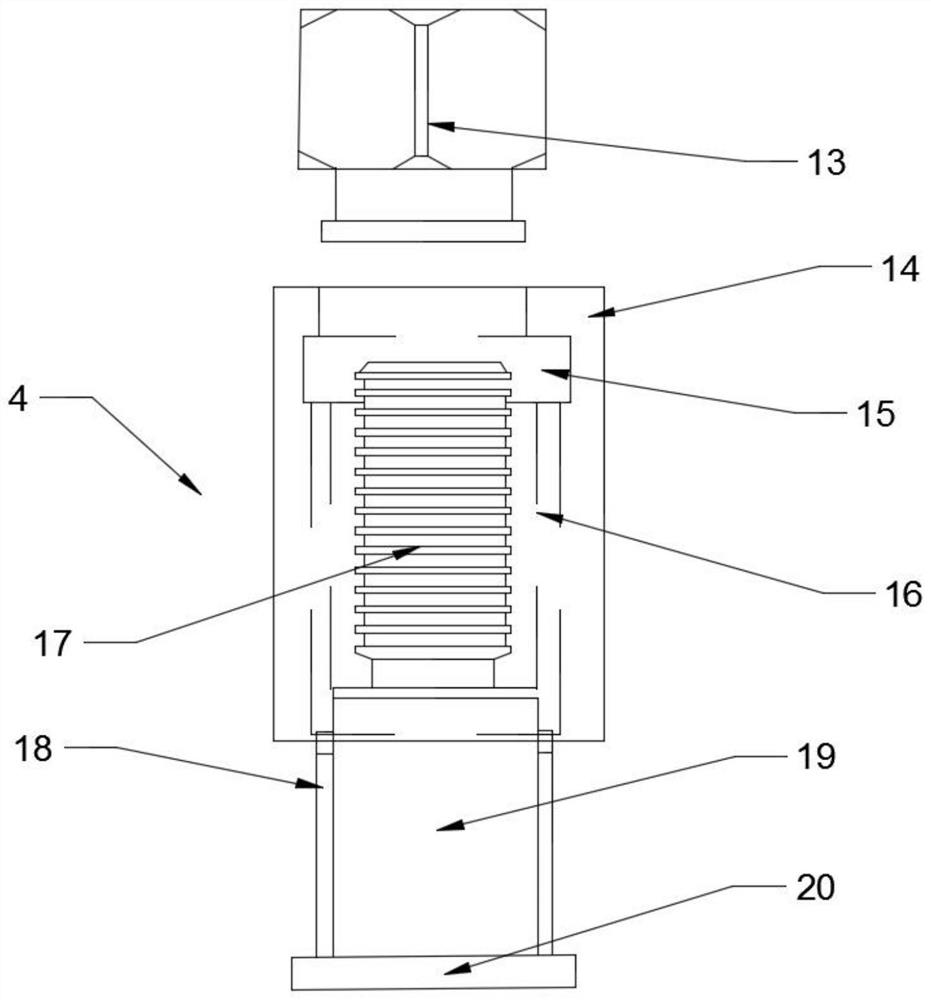

[0025] see image 3 Further, the locking assembly 4 includes a locking end 13, a movable cylinder 14 and a locking column 19, one end of the locking column 19 is provided with a stopper 20, and the other end of the locking column 19 is movably installed on the movable cylinder 14 inside, the locking column 19 is provided with a threaded section 17 on the part inside the movable cylinder 14; the internal thread of the locking end 13 is provided with the surface of the threaded section 17;

[0026] Specifically, a block 15 is provided inside the movable cylinder 14, and chute 16 is provided on both sides of the inner wall of the movable cylinder 14; protrusions 18 are provided on both sides of the locking column 19;

[0027] When the locking assembly 4 is used to connect the cover 3, the male head 2 and the female head 5 at the same time, one end of the locking post 19 provided with the threaded section 17 passes through the mounting hole 8 on the mounting plate 9 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com