Molded body of cu-al-mn shape memory alloy and method for producing the same

一种cu-al-mn、1.cu-al-mn的技术,应用在Cu-Al-Mn系形状记忆合金的成型体领域,能够解决螺纹精度变差、形状变形、无法充分发挥超弹性等问题,达到耐疲劳特性及耐断裂特性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0153] As a Cu-Al-Mn-based alloy, Al: 8.2 mass %, Mn: 10.7 mass %, and the remainder of the molded body raw material (Alloy No. 1 in Table 1) was used.

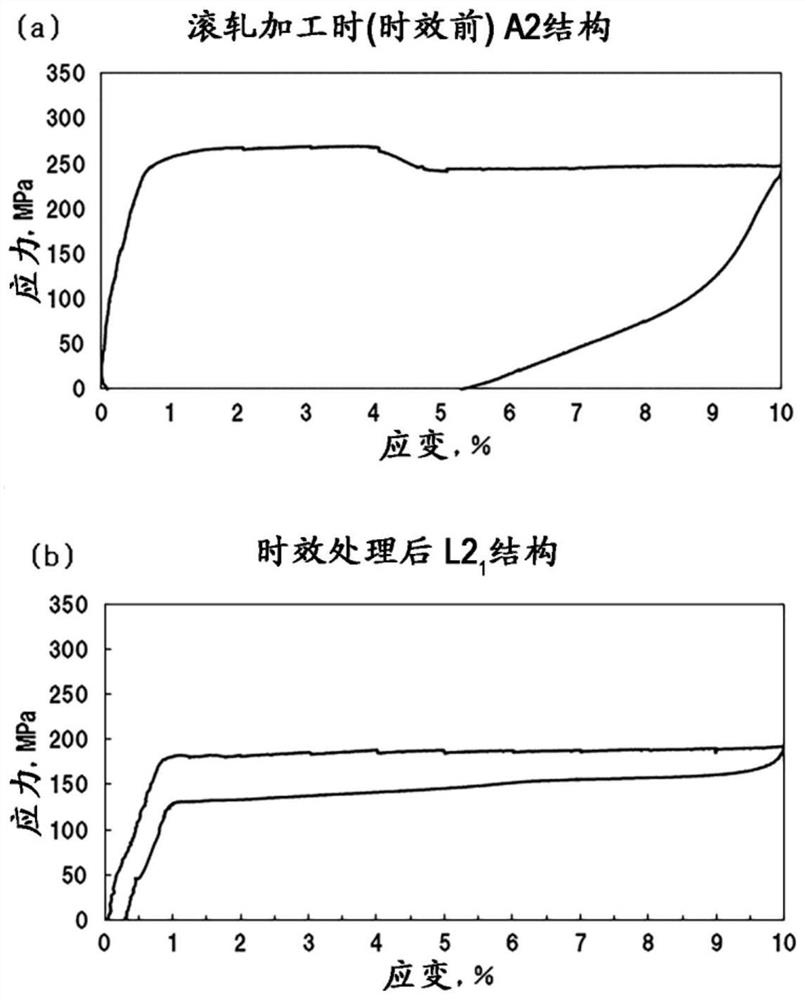

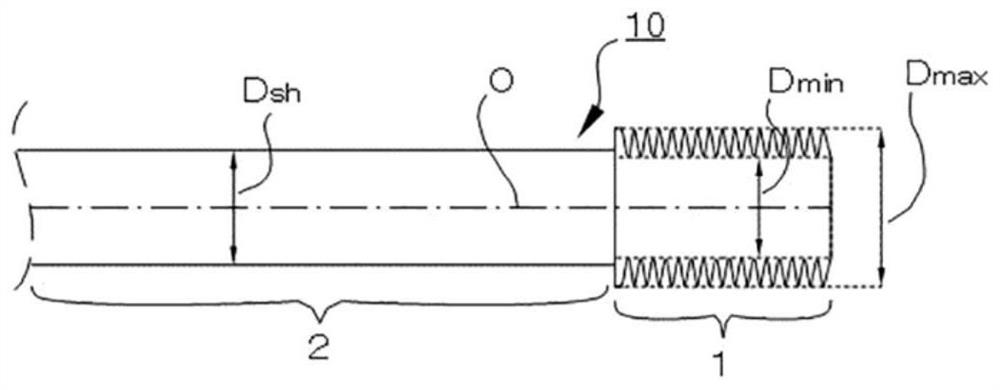

[0154] The material was melted and cast in a high-frequency vacuum melting furnace, hot forged at 800°C, hot rolled at 600°C, intermediate annealed at 520°C, cold drawn with a cold working rate of 40%, and produced with a diameter of 14 mm , Bars with a length of 300mm. The bar was heated to 500°C at a heating rate of 10°C / min in an electric furnace, held at 500°C for 1 hour, then reached 900°C at a temperature increase rate of 1.0°C / min, held at 900°C for 10 minutes, and then cooled by a 1.0°C / min to reach 500°C, hold at 500°C for 1 hour, then reach 900°C at a heating rate of 1.0°C / min, hold for 1 hour, and then quench in water to obtain a single crystal with a length of 300mm and a crystal structure It is a bar of A2 type structure. Then, by lathe machining and centerless grinding, the bar with a diameter of 14mm is made ...

Embodiment 8~11

[0159] The manufacturing method was the same as that of Example 4, except that the heat treatment temperature after thread rolling was 60° C., 80° C., 300° C., and 400° C., respectively, and the heat treatment time was 30 minutes of aging heat treatment. Each of the above-mentioned evaluations was performed on the obtained threaded rod. The obtained results are shown in Table 4.

[0160] As a result, as shown in Table 4, in Examples 8 to 11, threading was possible, and especially in Examples 9 and 10, excellent superelasticity, fatigue resistance, and fracture resistance were obtained. In Example 8, the heat treatment temperature after the thread rolling process is low, from the disordered A2 type structure to the ordered structure L2 1 Insufficient change of the shape structure, insufficient superelasticity, and large superelastic residual strain. As a result of Example 11, the heat treatment temperature after thread rolling was high, the Vickers hardness ratio (Hs / Ho ratio...

Embodiment 12~40

[0162] The production method was the same as that of Example 4, but as the components of the Cu-Al-Mn-based alloy, the blending amounts of Al and Mn, and the types and blending amounts of optional additional elements were changed as shown in Tables 1 to 3. Composition (Alloy Nos. 2 to 30 in Tables 1 to 3). Each of the above-mentioned evaluations was performed on the obtained threaded rod. The obtained results are shown in Tables 5 and 6.

[0163] [table 5]

[0164]

[0165] [Table 6]

[0166]

[0167] As a result, as shown in Tables 5 and 6, in Examples 12 to 40, threading was possible. In particular, Examples 13 to 40 had good superelasticity, fatigue resistance, and fracture resistance. In addition, as a result of Example 12, the Al content was slightly high, and the fracture resistance was poor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com