Heating element heating program control method and method for improving uniformity of flue gas release

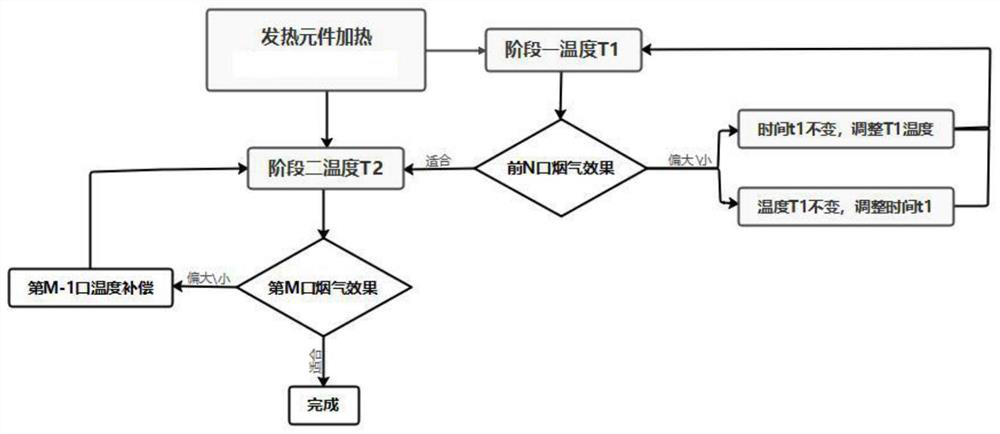

A heating element and heating program technology, applied to tobacco and other directions, can solve the problems of inaccurate determination of heating curve, reduction of flue gas volume, uneven flue gas release, etc., and achieve the effect of precise and accurate determination of the adjustment method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

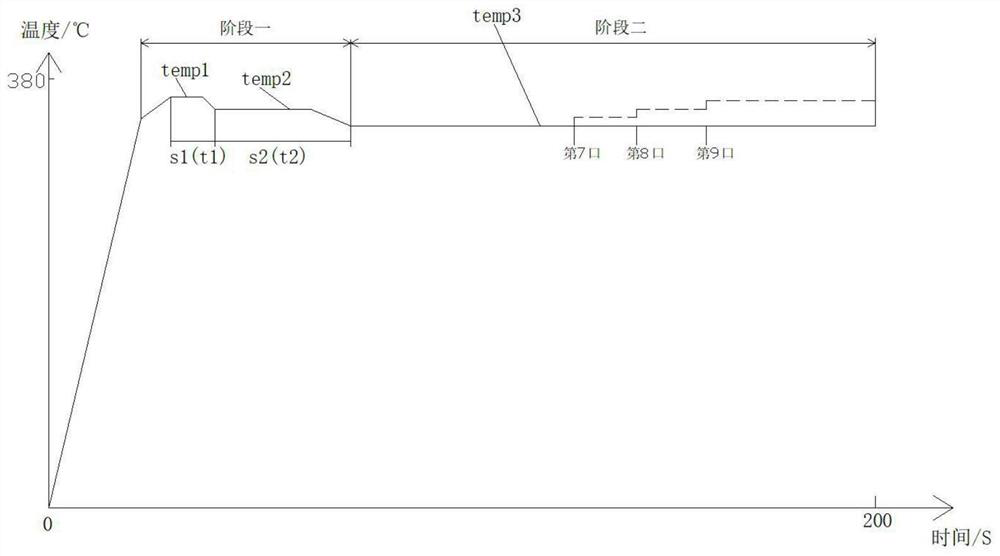

[0041] like figure 2 As shown, there are two stages of temperature in the preheating stage and the suction stage. The preheating stage is divided into two small stages s1 and s2. The durations of the two small stages s1 and s2 in the preheating stage are respectively When t1=10 seconds and t2=20 seconds, the duration of the preheating stage is 30 seconds. The temperatures corresponding to the times t1 and t2 in the preheating stage are temp1=350°C and temp2=340°C. If the smoke volume of the first 3 puffs of smoke is less than 1mg / puff, keep the time of the preheating stage unchanged, and increase the temperature of the preheating stage, that is, increase temp1 and temp2 by 10 °C, respectively, to obtain temp1=360 ℃, temp2=350℃; or the temperatures temp1 and temp2 in the preheating stage remain unchanged, the duration t1 of the temperature in the s1 stage in the preheating stage is set to 20 seconds, and the duration t2 of the temperature in the s2 stage is set to 10 seconds,...

Embodiment 2

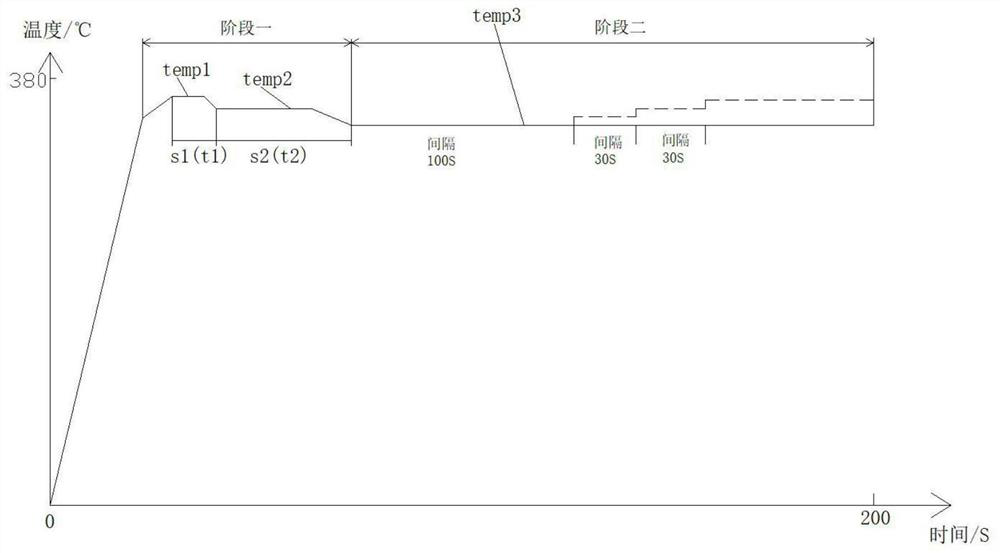

[0045] like image 3 As shown, the debugging method in the preheating stage is the same as that in Example 1, the temperature temp3 in the suction stage is 340°C, the timing starts when the suction stage is entered, and the temperature temp3 in the suction stage is increased by 10°C when the time reaches 100 seconds (at this time the suction The temperature of the suction stage is 350 °C), and then the temperature of the suction stage obtained after the previous temperature increase is increased by 10 °C within 130 seconds of the working time of the suction stage (the temperature of the suction stage at this time is 360 °C) , and then at 160 seconds of the working time of the suction stage, the temperature of the suction stage obtained after the previous temperature increase was increased by 10 °C (the temperature of the suction stage at this time was 370 °C).

[0046] The present invention has been exemplarily described above. It should be noted that, without departing from t...

Embodiment 3

[0048] In this example, there are two stages of temperature in the preheating stage and the suction stage. The preheating stage is divided into two small stages s1 and s2. The durations of the two small stages s1 and s2 in the preheating stage are t1=10 respectively. seconds, t2=20 seconds, the duration of the preheating phase is 30 seconds. The temperatures corresponding to the times t1 and t2 in the preheating stage are temp1=360°C and temp2=350°C. The smoke volume of the first 3 puffs, the smoke concentration value is 3mg / puff, and the smoke volume is moderate, the heating temperature T2 will not be adjusted, and the heating duration is t2;

[0049] In the suction stage, the temperature temp3 = 350°C. When the 8th puff is puffed, the smoke concentration is 2 mg / puff, and the smoke volume is moderate. The heating temperature T2 is no longer adjusted, and the heating duration is t2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com