Chili mashing device for making chili powder

A technology for chili noodles and chili peppers, which is applied in grain processing and other directions, can solve the problems of reducing work efficiency, time-consuming and laborious, etc., and achieve the effects of improving work efficiency, facilitating material reclaiming work, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

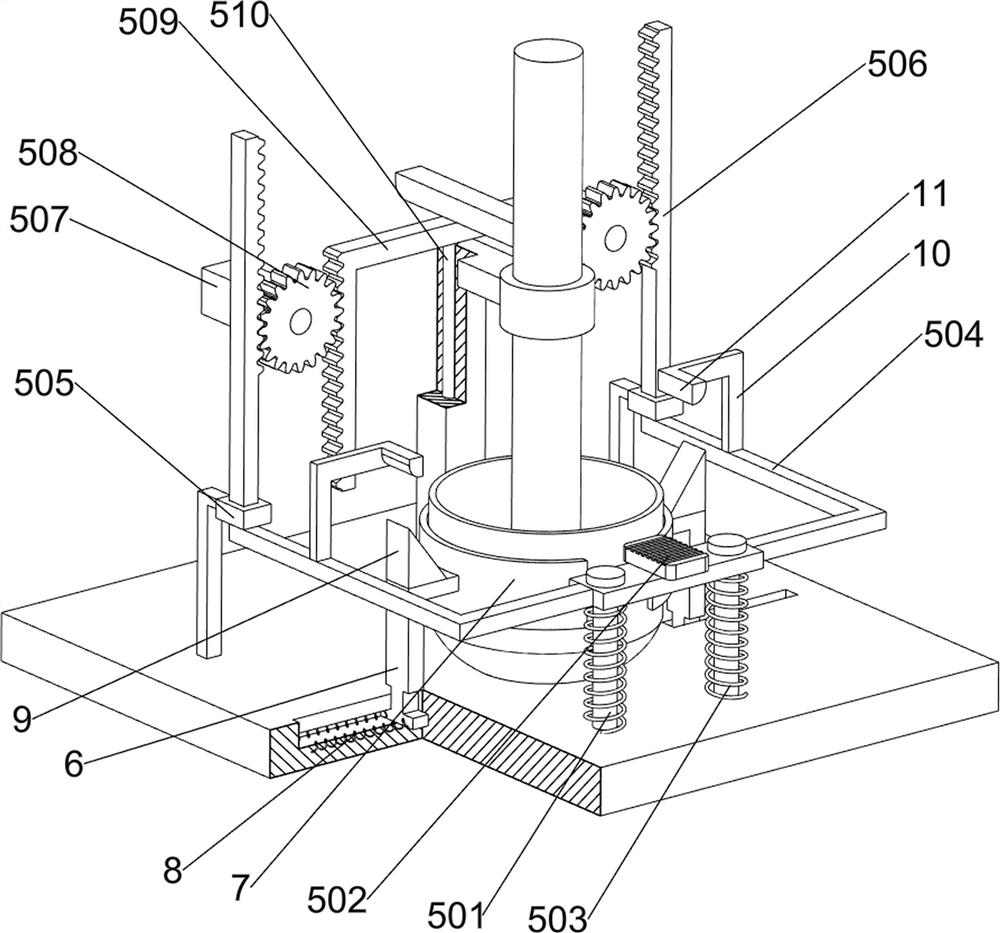

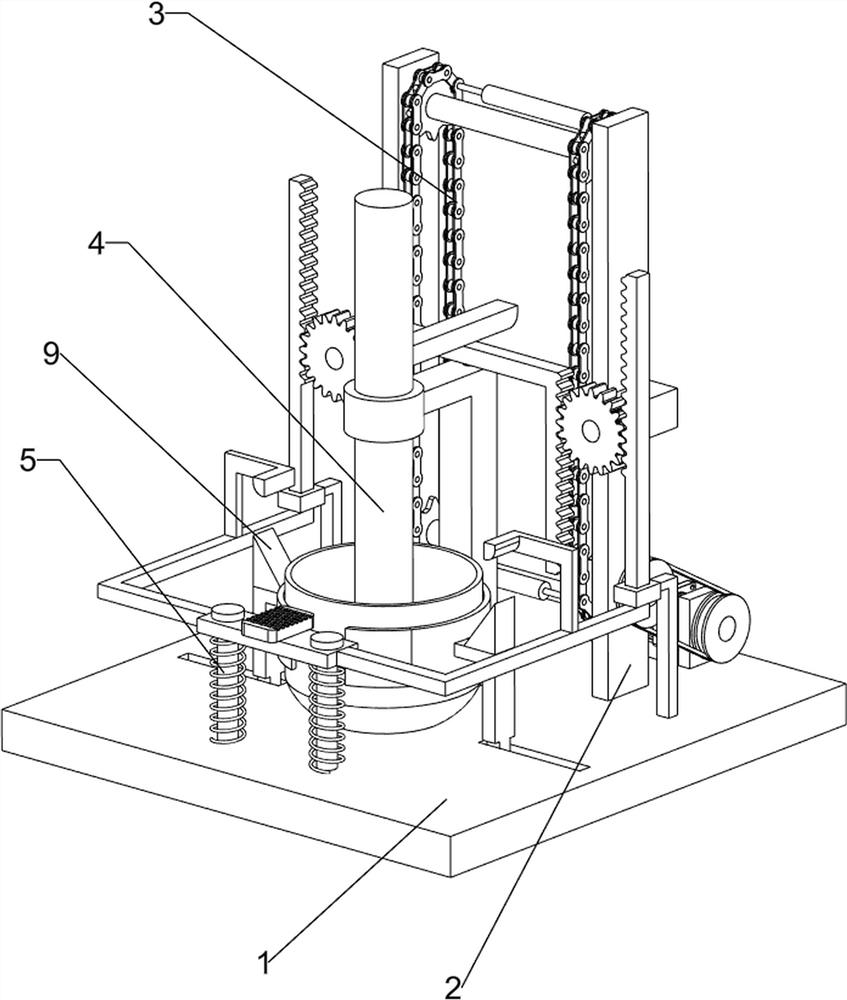

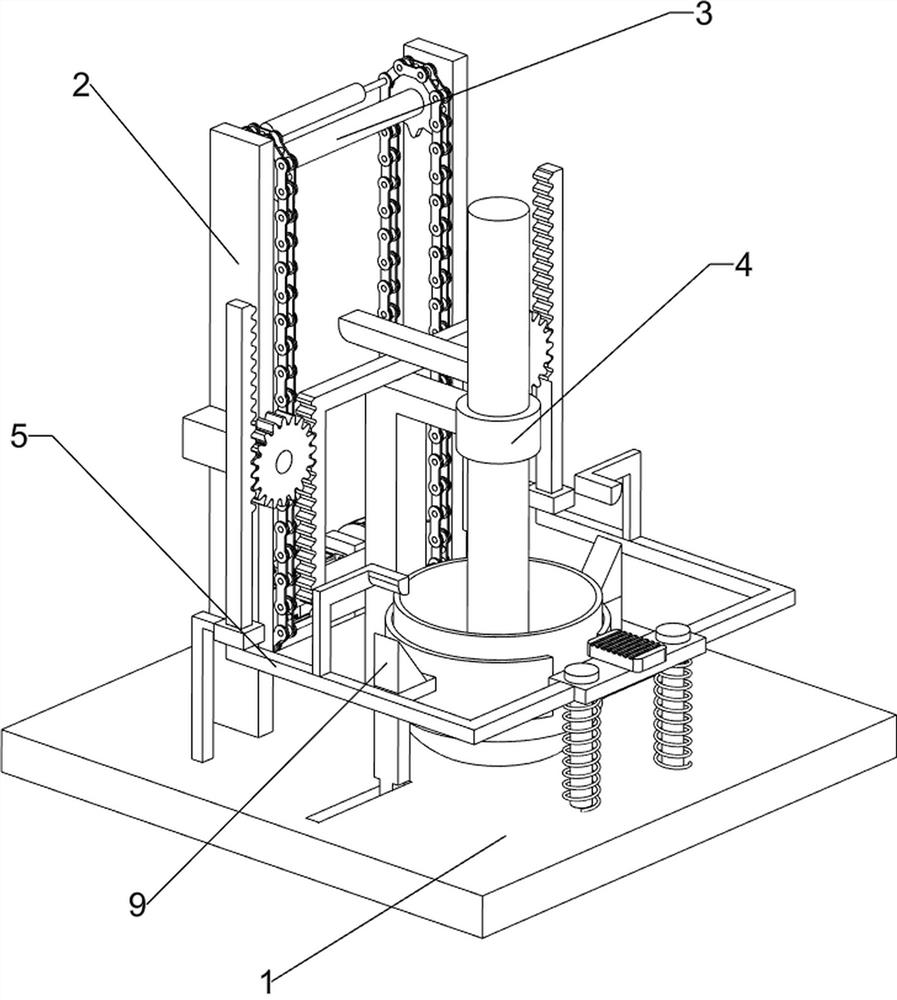

[0024] A kind of chili powder is made and is used for chili crushing device, as Figure 1-Figure 4 As shown, it includes a base 1, a support frame 2, a drive assembly 3 and a smashing assembly 4. The left and right sides of the upper rear part of the base 1 are provided with a support frame 2, the support frame 2 is provided with a drive assembly 3, and the upper middle of the base 1 is provided with a support frame 2. There are mashing components 4.

[0025] People place the pepper in the mashing assembly 4, then start the driving assembly 3, the driving assembly 3 will drive the mashing assembly 4 to move upwards, when the driving assembly 3 is separated from the mashing assembly 4, due to the gravity factor, the mashing assembly 4 Move downwards to contact the pepper, so that the smashing work is completed, and people close the drive assembly 3 to get final product.

[0026] The driving assembly 3 includes a servo motor 301, a transmission wheel 302, a transmission belt 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com