Patents

Literature

39results about How to "Convenient pick-up work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

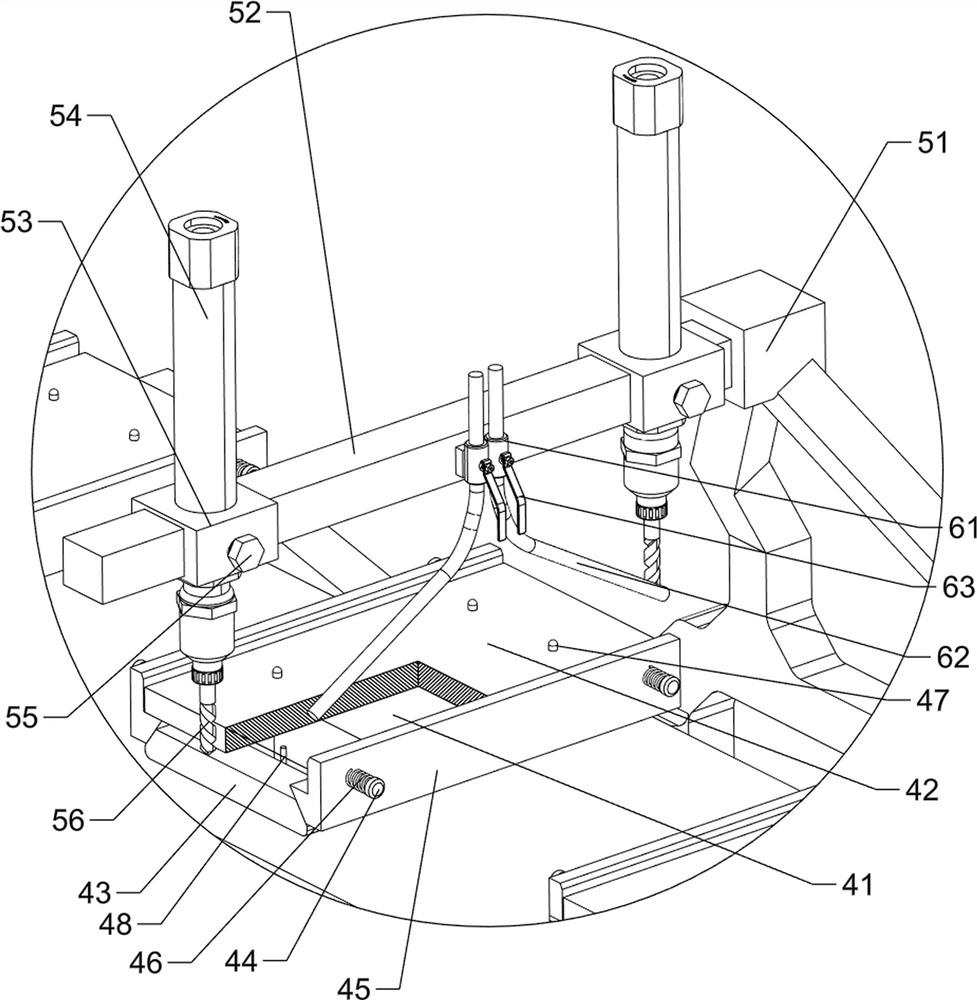

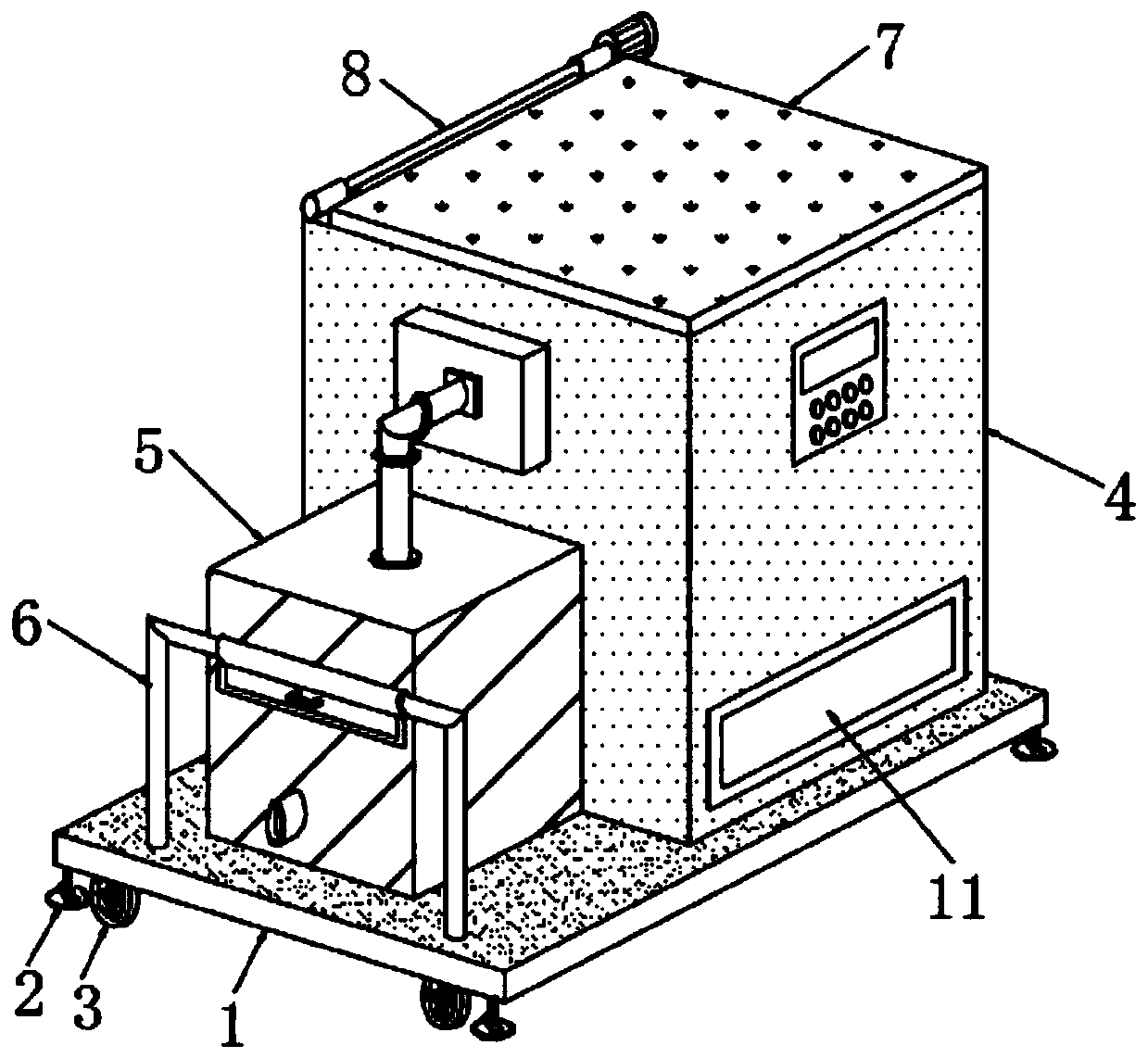

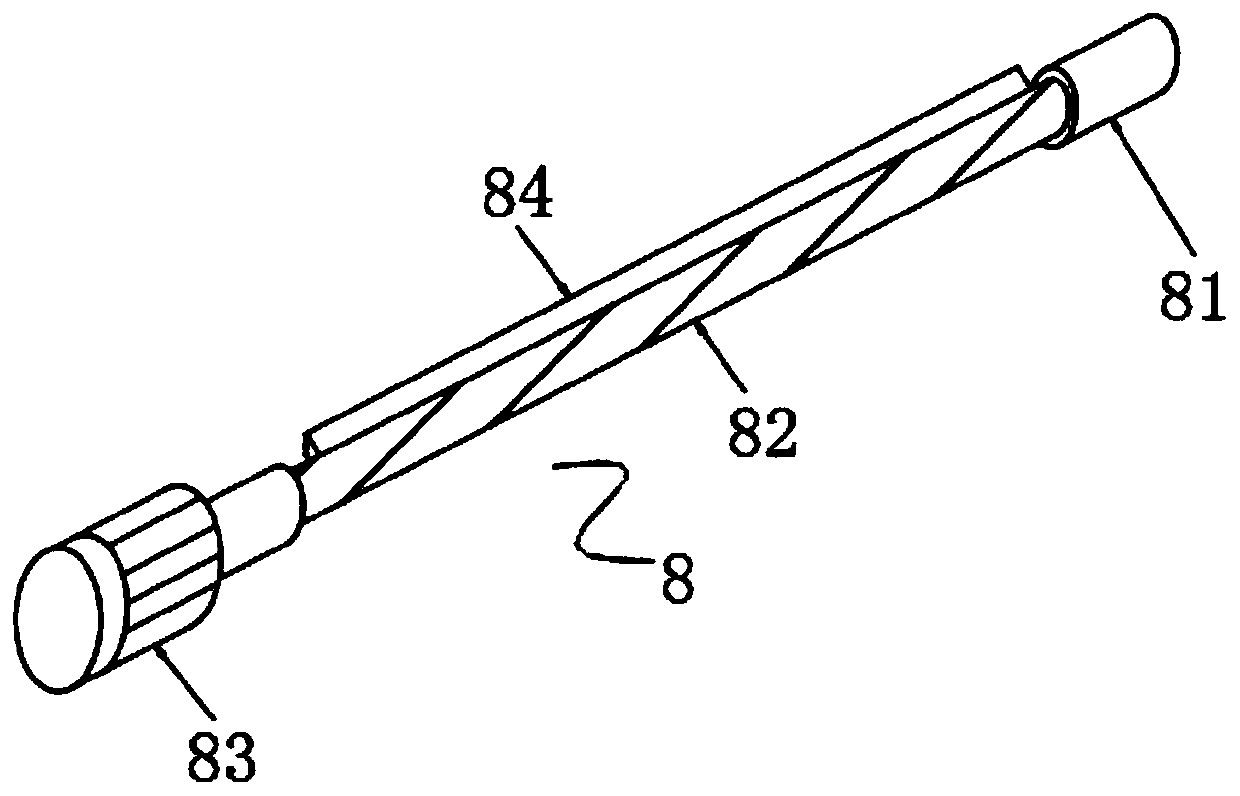

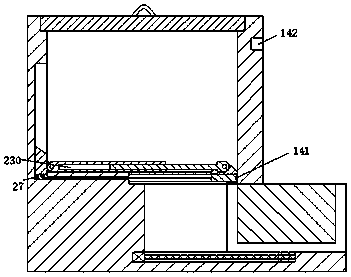

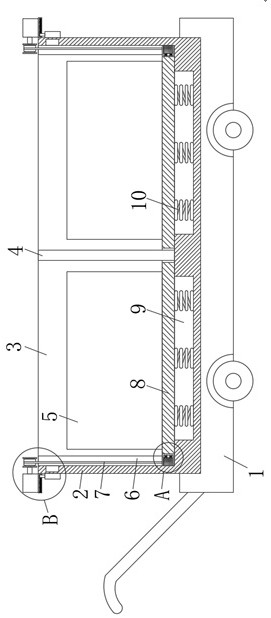

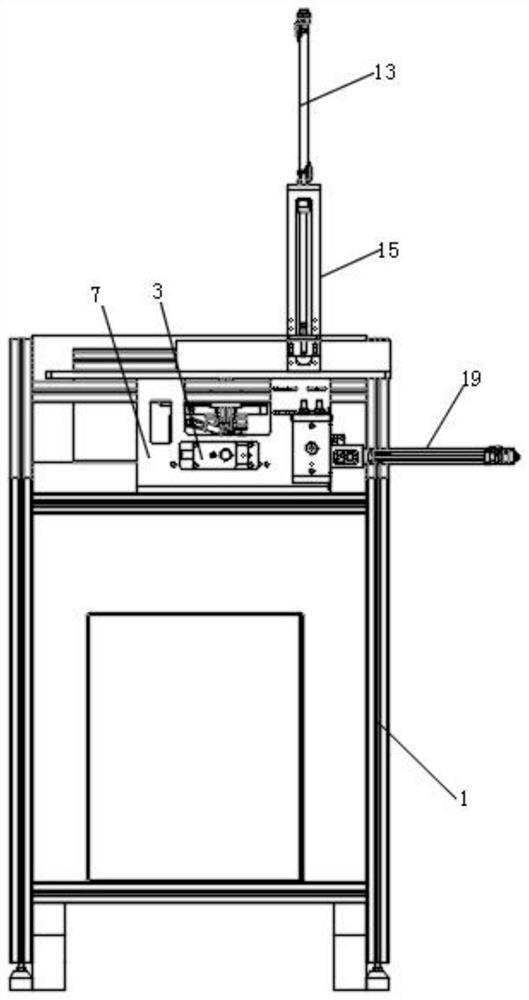

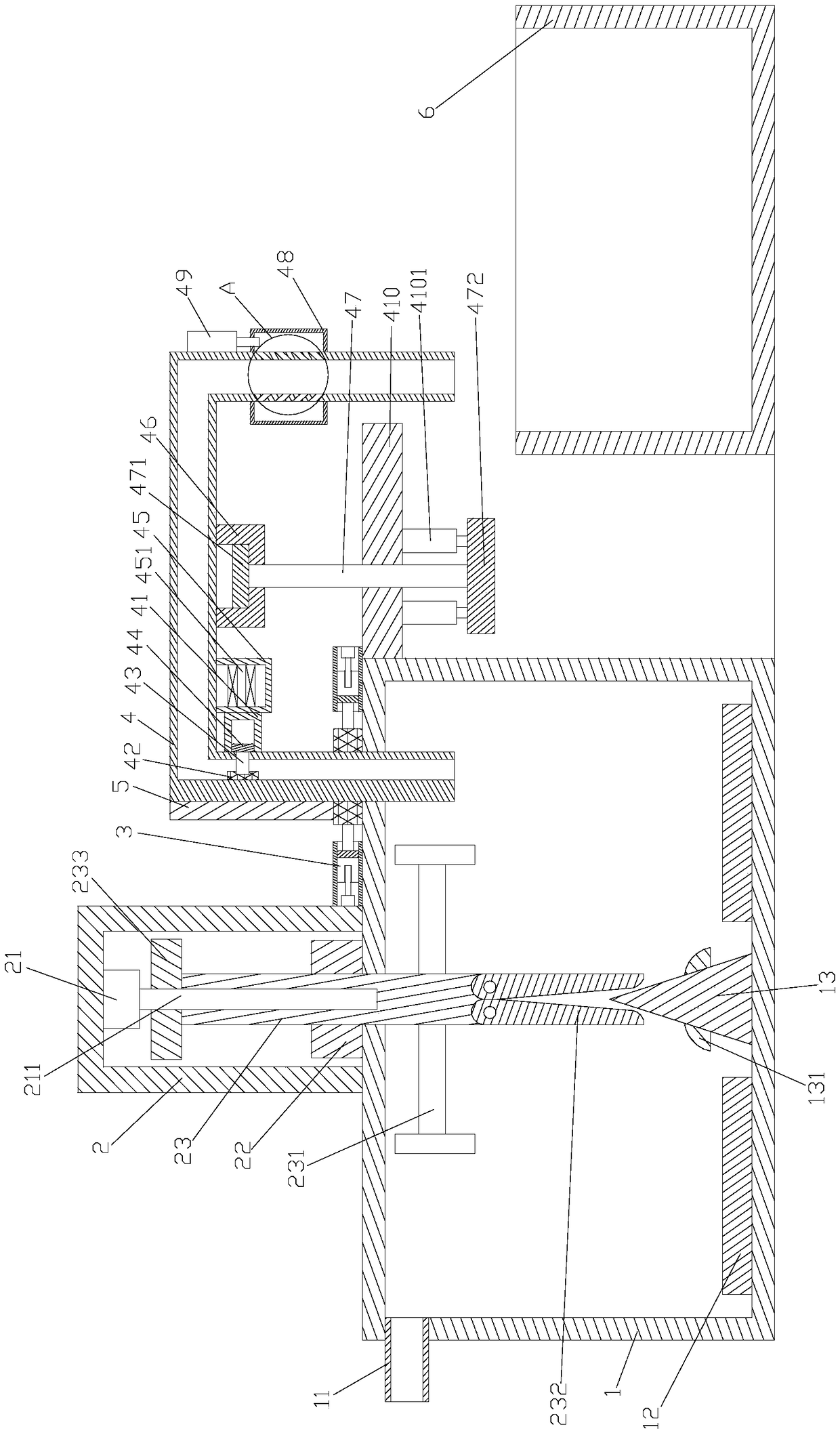

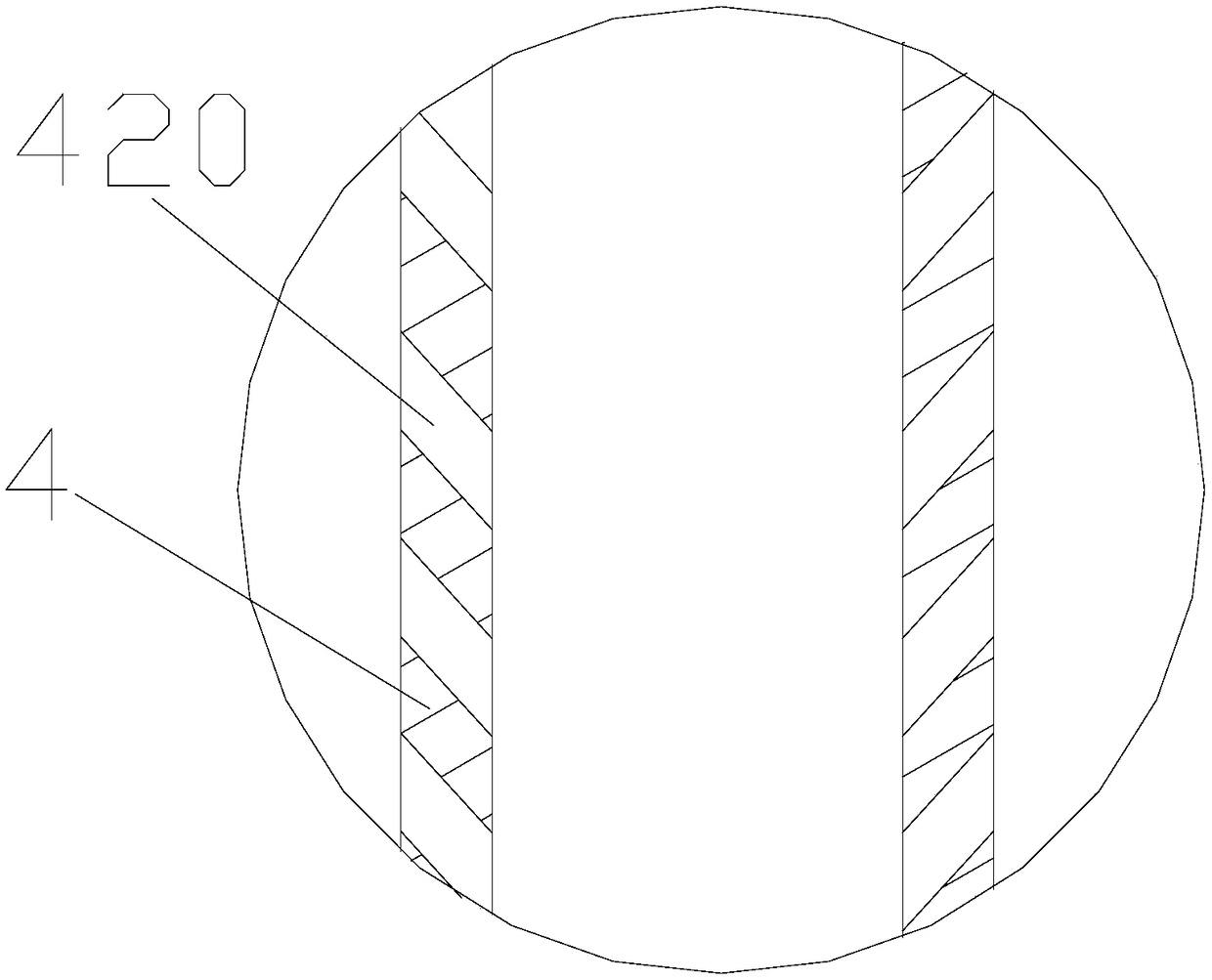

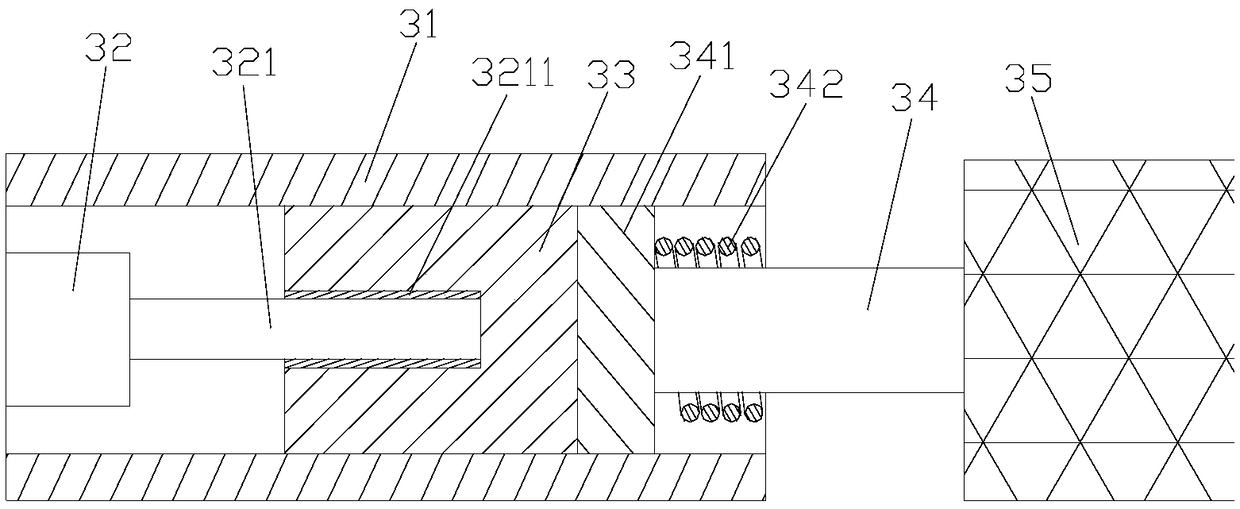

Polishing equipment for edge opening of high-frequency plate after drilling

InactiveCN112388425AImprove work efficiencyGood sandingEdge grinding machinesGrinding drivesPolishingElectric machinery

The invention relates to polishing equipment, in particular to polishing equipment for an edge opening of a high-frequency plate after drilling. The invention aims to provide the polishing equipment for the edge opening of the high-frequency plate after drilling, wherein the equipment is capable of performing automatic polishing and automatically taking materials and is simple to operate. According to the technical scheme, the polishing equipment for the edge opening of the high-frequency plate after drilling comprises a base, a motor, feeding mechanisms, clamping mechanisms, and a polishing mechanism. The motor is arranged in the middle of the base; the feeding mechanisms are arranged at two sides of the upper part of the base; the clamping mechanisms are arranged on the feeding mechanisms; and the polishing mechanism is arranged at the middle side of the upper portion of the base. The equipment has the beneficial effects that under the action of the polishing mechanism, people startan air grinder and the motor, the motor can drive a first transmission assembly to rotate, clamping assemblies can drive wedge-shaped baffles to move towards the inner side, and therefore the high-frequency plate is clamped, and a bottom plate can continue to drive the high-frequency plate to move towards the rear side; and when the high-frequency plate is in contact with a cutter, the cutter canpolish the high-frequency plate, so that the working efficiency of people is effectively improved.

Owner:赖学良

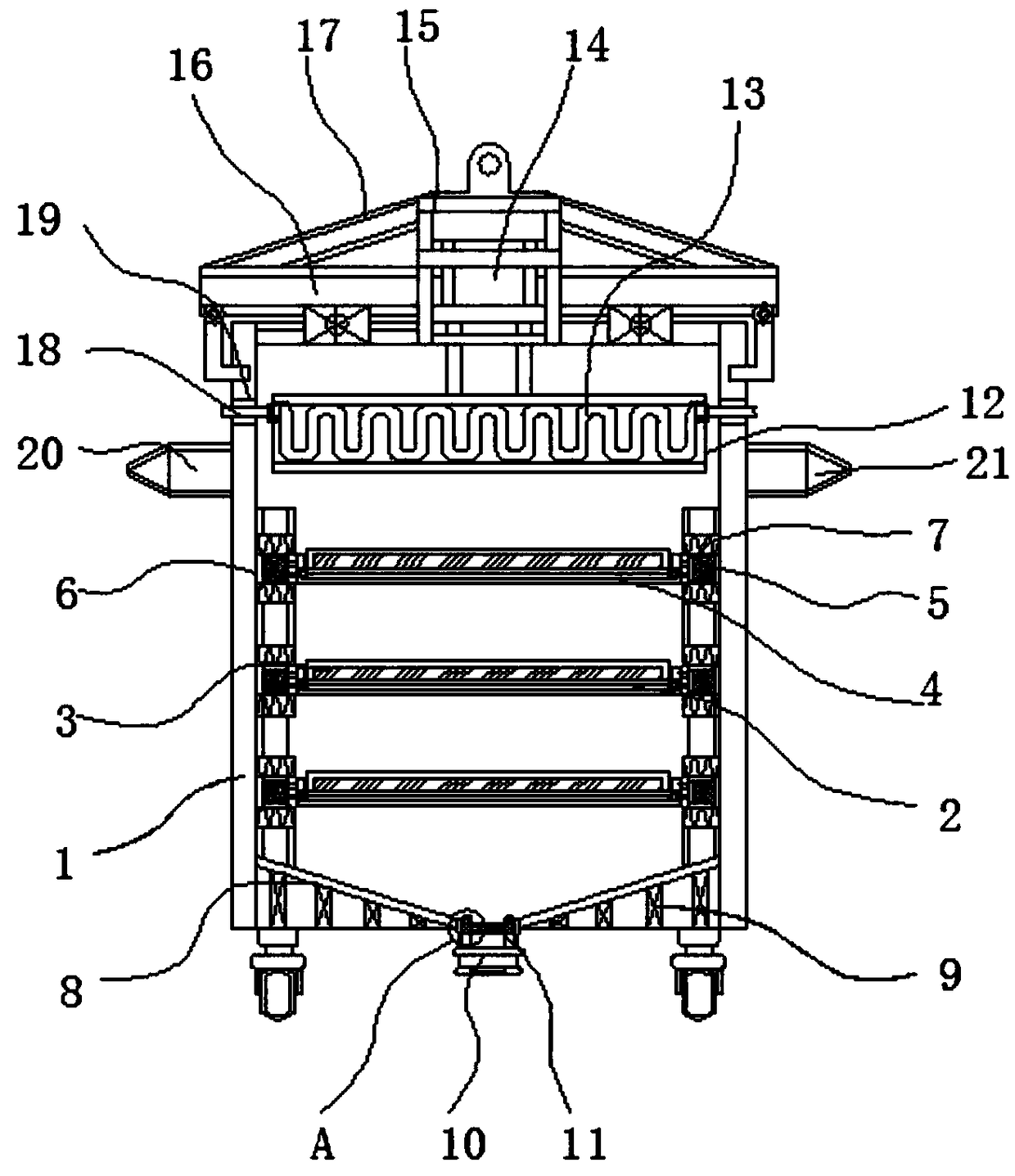

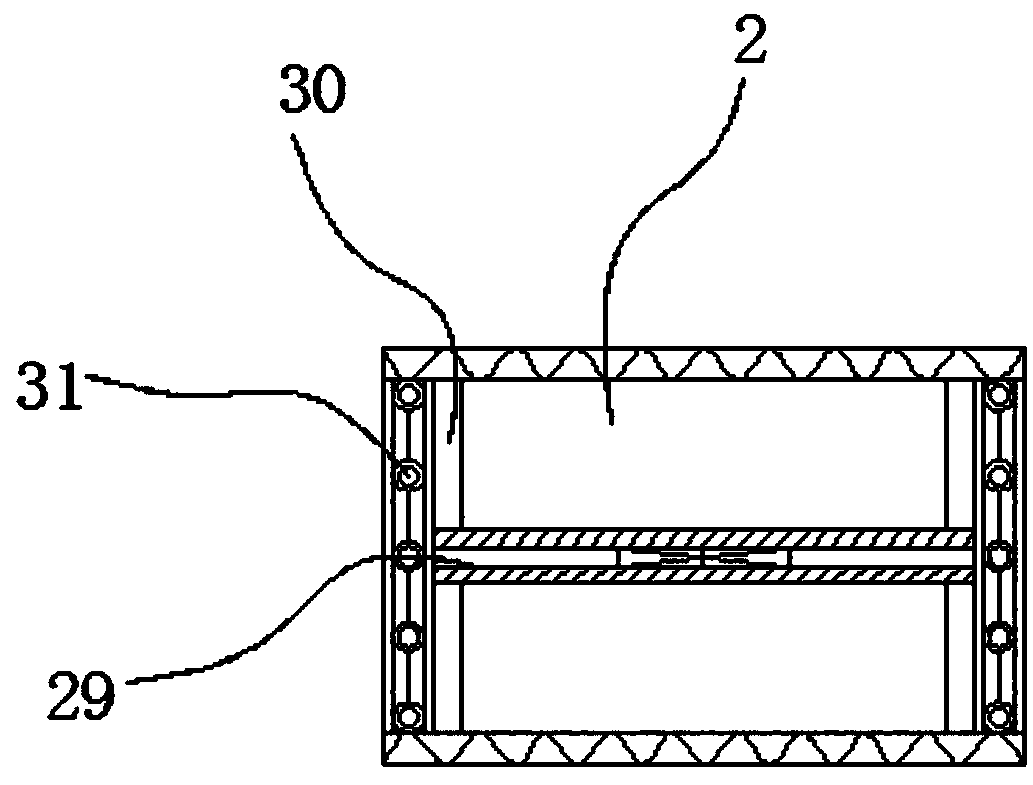

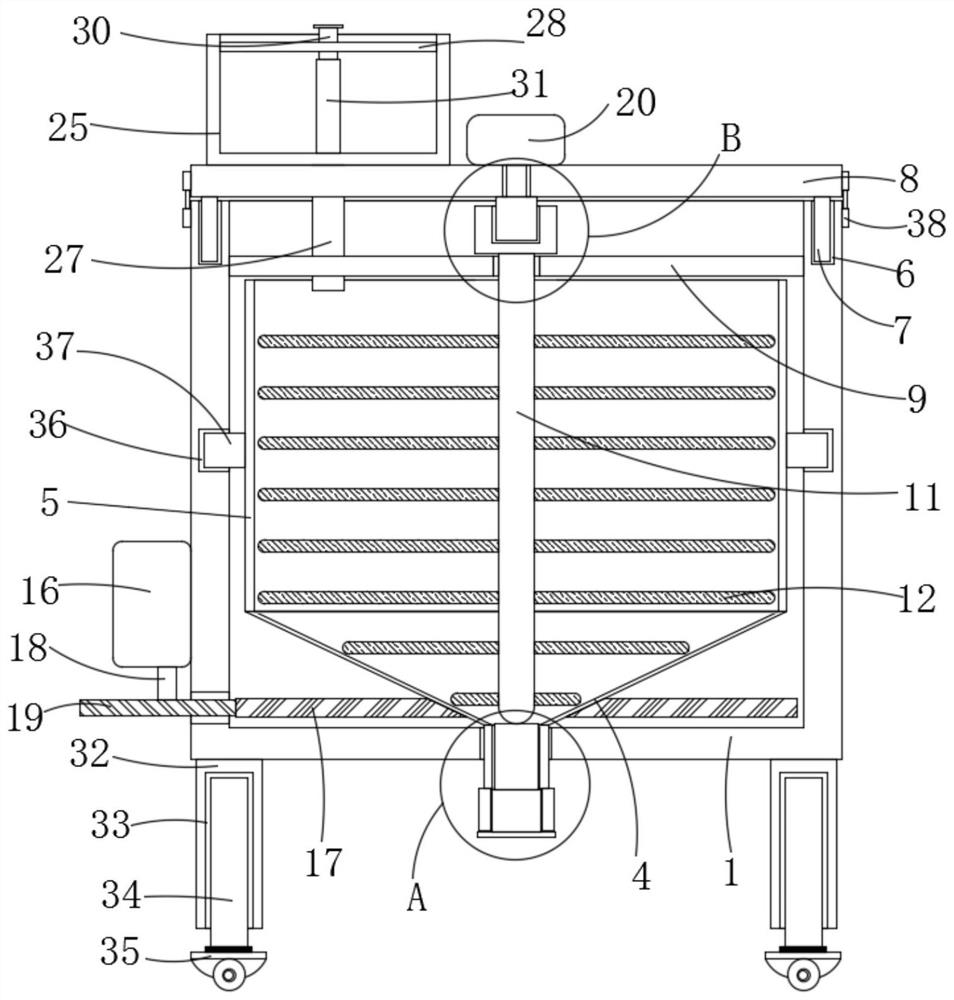

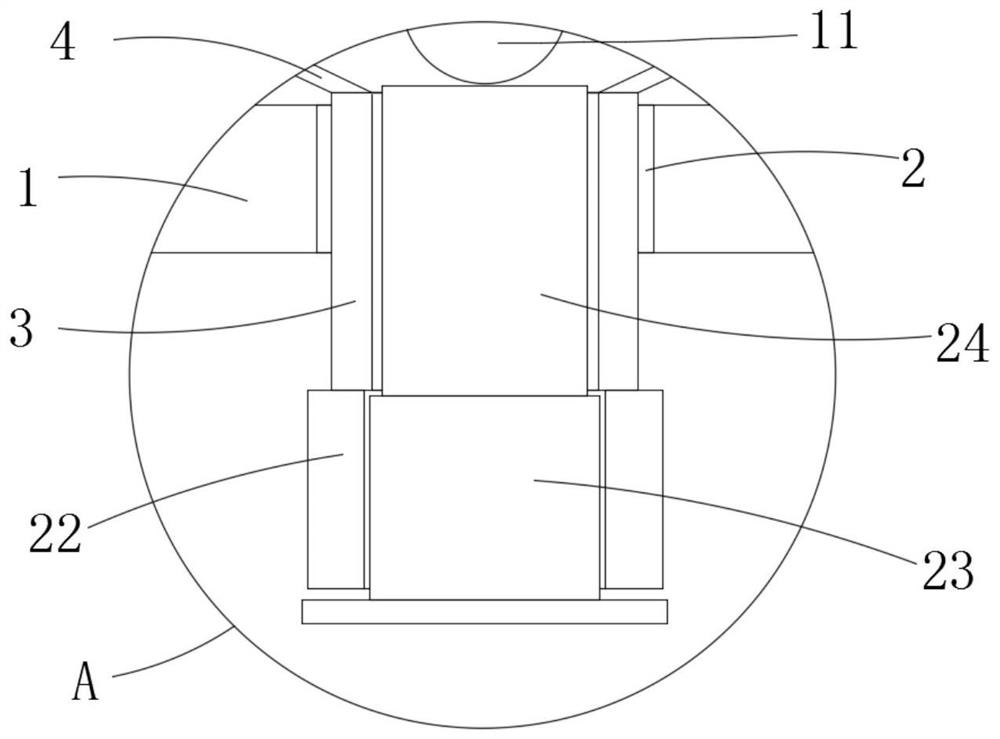

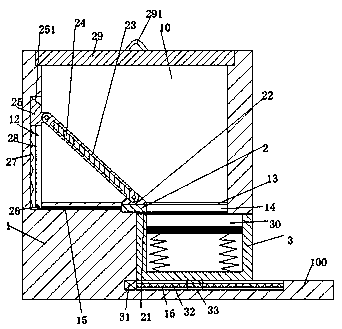

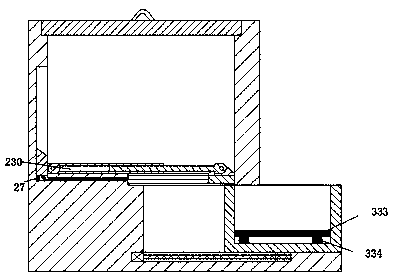

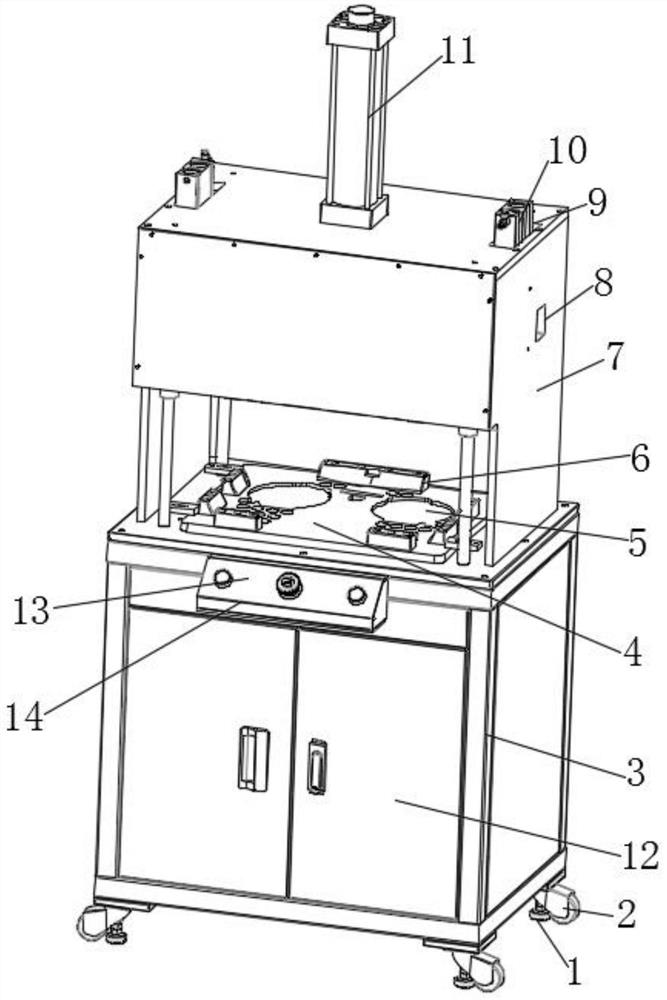

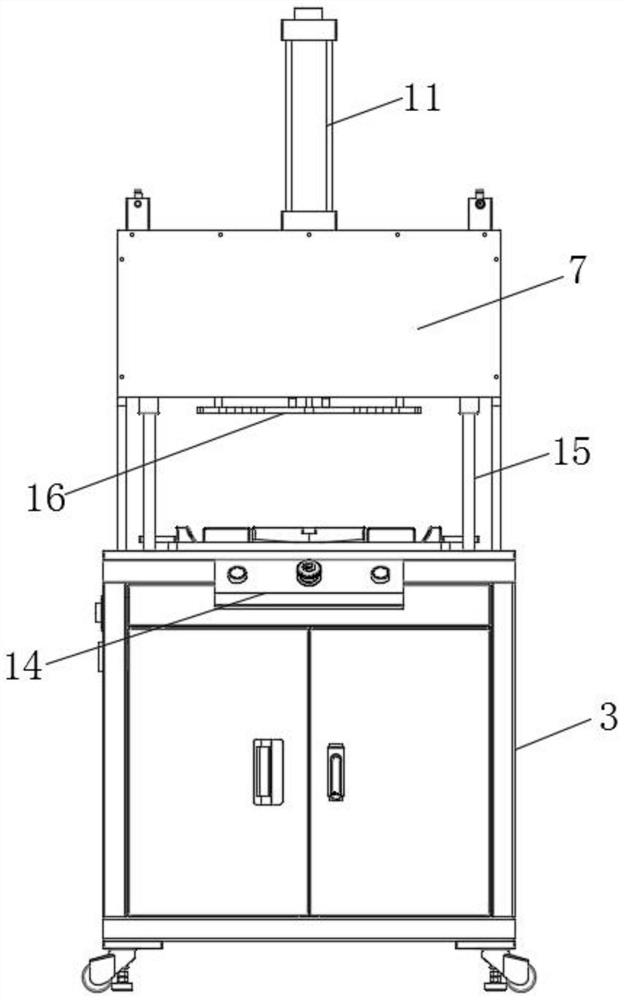

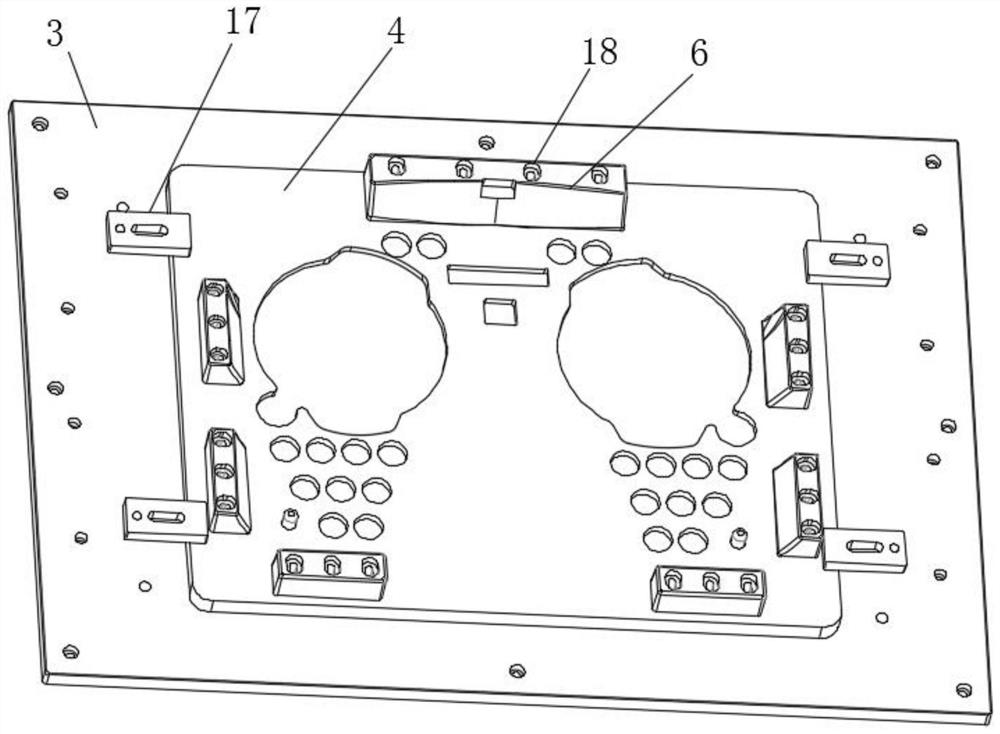

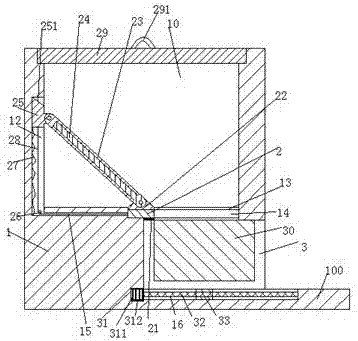

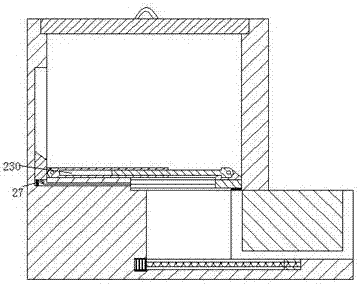

Baked food cooling box for food processing

InactiveCN109221345AAvoid damageIntegrity guaranteedPreservation by coolingCooking & bakingBaked goods

The invention discloses a baked food cooling box for food processing, and relates to the technical field of food processing. The baked food cooling box comprises a cooling box body and a cooling framework, baking trays are installed inside the cooling box body, the cooling framework is arranged over the baking trays, and the baking trays are connected with the cooling box body through grooves; guide slide wheels are installed at the left and right ends of each baking tray, a partition board is movably connected to the front of each baking tray, a cooling pipeline is installed inside the cooling framework, and the top of the cooling framework is in threaded connection with a hydraulic air cylinder. The baked food cooling box for food processing has the advantages that through the arrangement of the cooling box body, a turnover cover plate and the cooling framework, when the turnover cover plate covers the top of the cooling box body, the cover plate and the cooling box body are combinedto form a relative sealed shell. Through the cooperation of the cooling framework, food inside the cooling box body can be hermetically cooled.

Owner:FOSHAN UNIVERSITY

Multifunctional automatic fruit bagging device

InactiveCN112845036AGood cleaning effectConvenient feeding and fruit separationSievingScreeningHorticultureAgricultural engineering

Owner:合肥利晟科技有限公司

Machining mold structure capable of achieving cooling conveniently

InactiveCN111452276AReduce the temperatureEasy to circulate coolingFoundry mouldsFoundry coresWater storageWater storage tank

The invention discloses a machining mold structure capable of achieving cooling conveniently, and relates to the technical field of mold equipment. The machining mold structure comprises a base, a supporting frame and a fixed box. The supporting frame is fixedly arranged at the top of the base. The fixed box is fixedly arranged at one end of the base. An electric push rod is fixedly mounted at thebottom end of the top of the supporting frame. An upper mold cavity is fixedly mounted at the bottom of the electric push rod. A fixed groove is formed on the surface of the base. A second water pumpis arranged to slowly draw water in a water storage box into a cooling water box through a connecting water pipe and a cooling water pipe, cold water is attached and fixed to the fixed groove throughthe cooling water pipe when passing through the cooling water pipe, and therefore the temperature of a mold in a lower mold cavity is reduced through cold water; and then the temperature of water drained into the cooling water box is reduced through a stirring shaft and fans together, water is drawn into the water storage box again through the connecting water pipe via a first water pump, the effect of achieving cyclic cooling conveniently is achieved, and meanwhile the effect of saving water resources is achieved.

Owner:重庆九海铝业有限公司

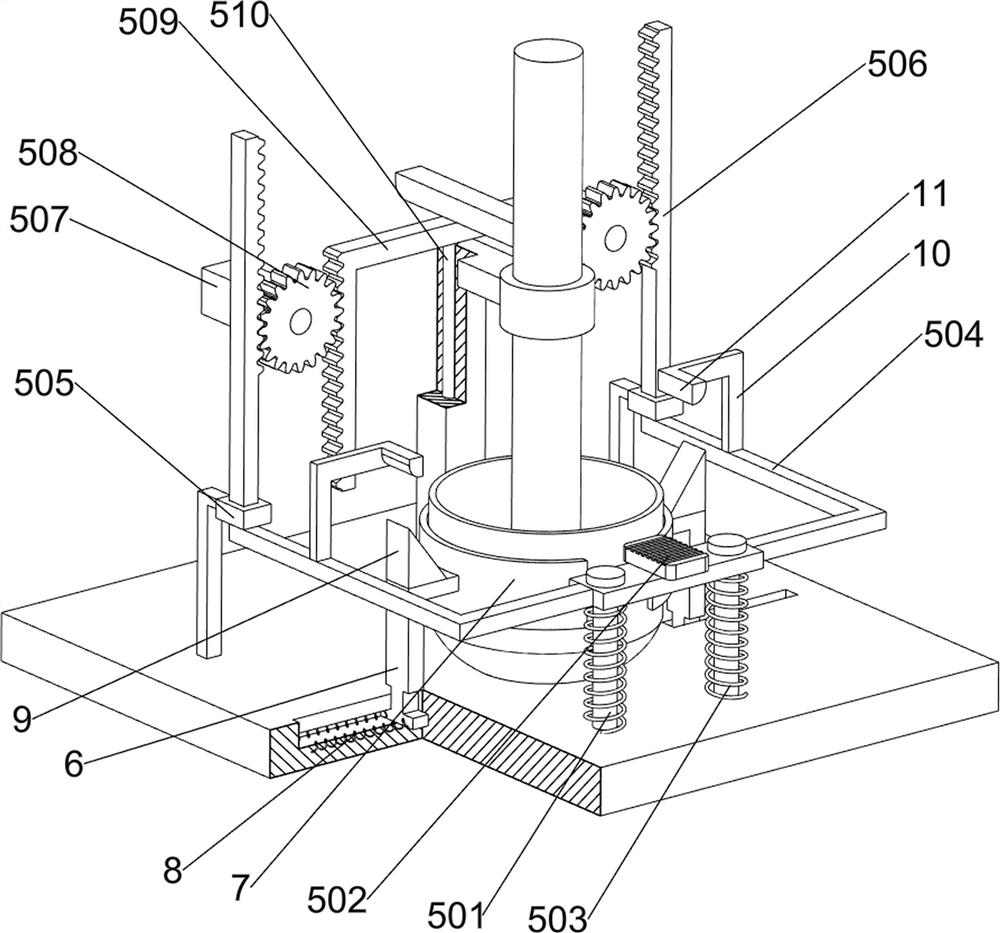

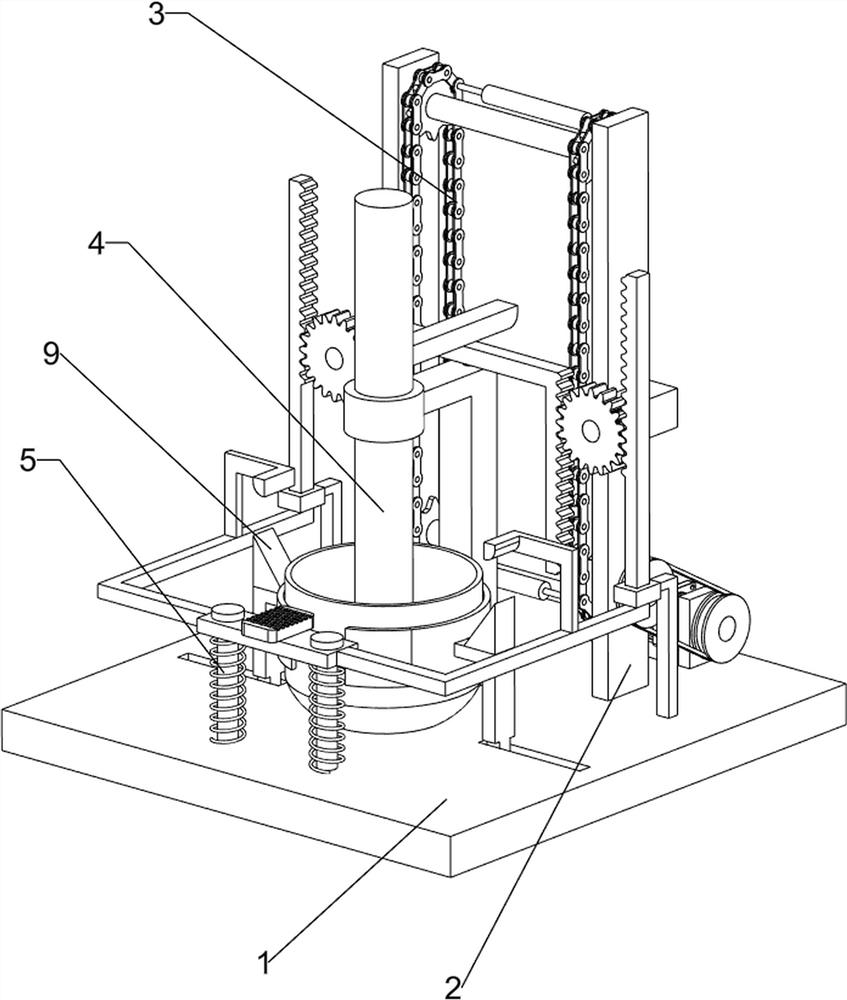

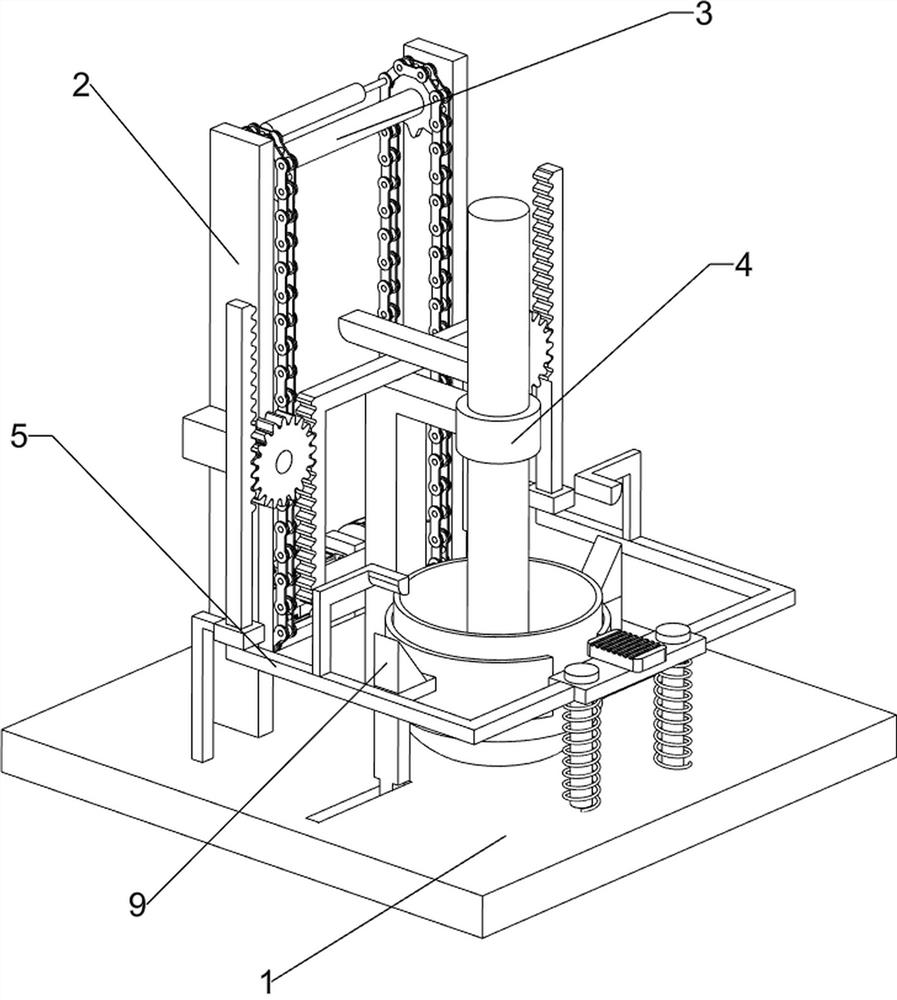

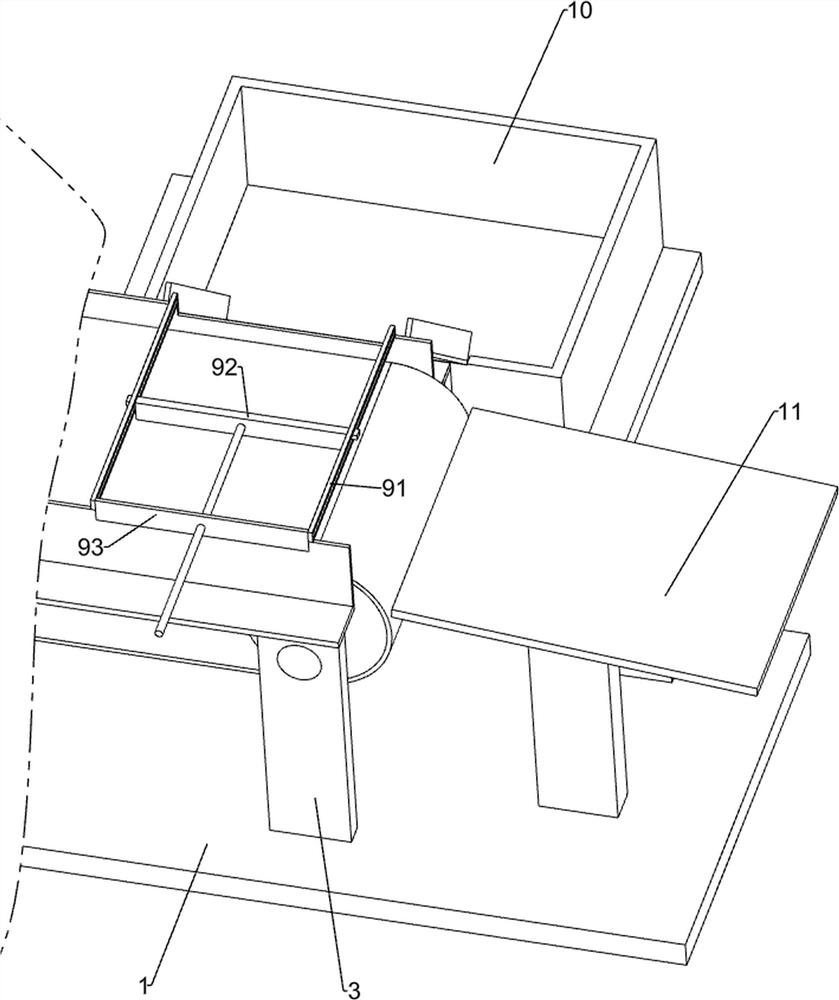

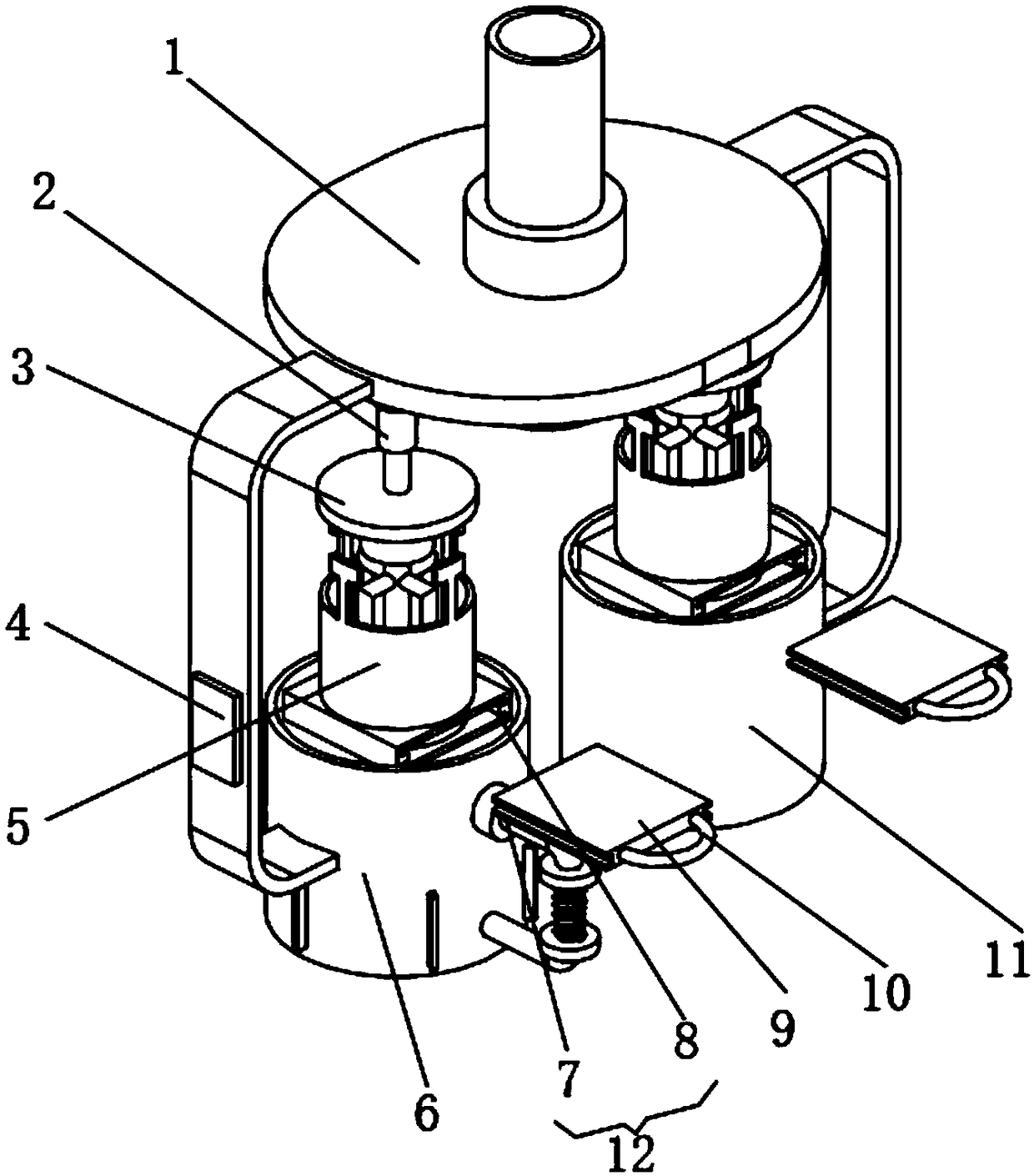

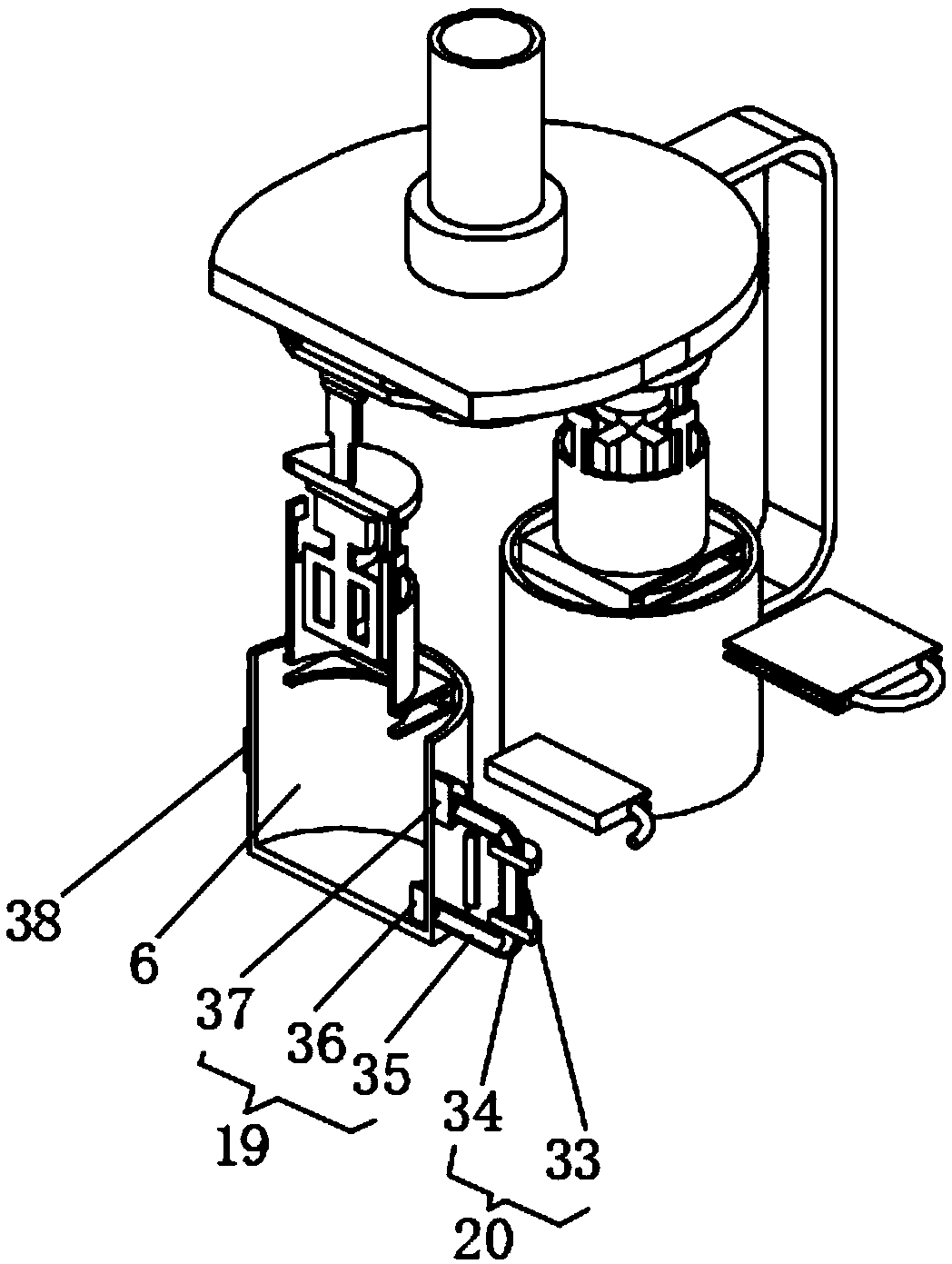

Chili mashing device for making chili powder

ActiveCN112844545AImprove work efficiencyConvenient pick-up workClimate change adaptationGrain treatmentsMechanical engineeringChili pepper

Owner:汝城县繁华食品有限公司

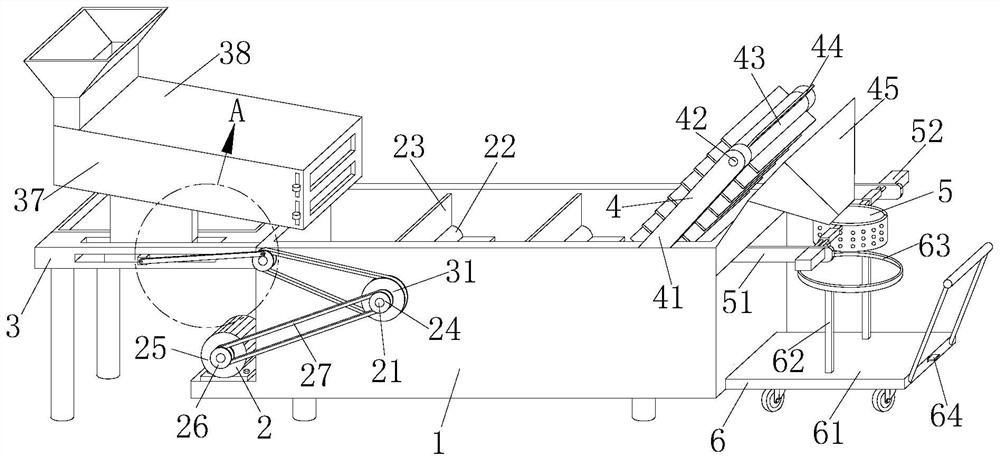

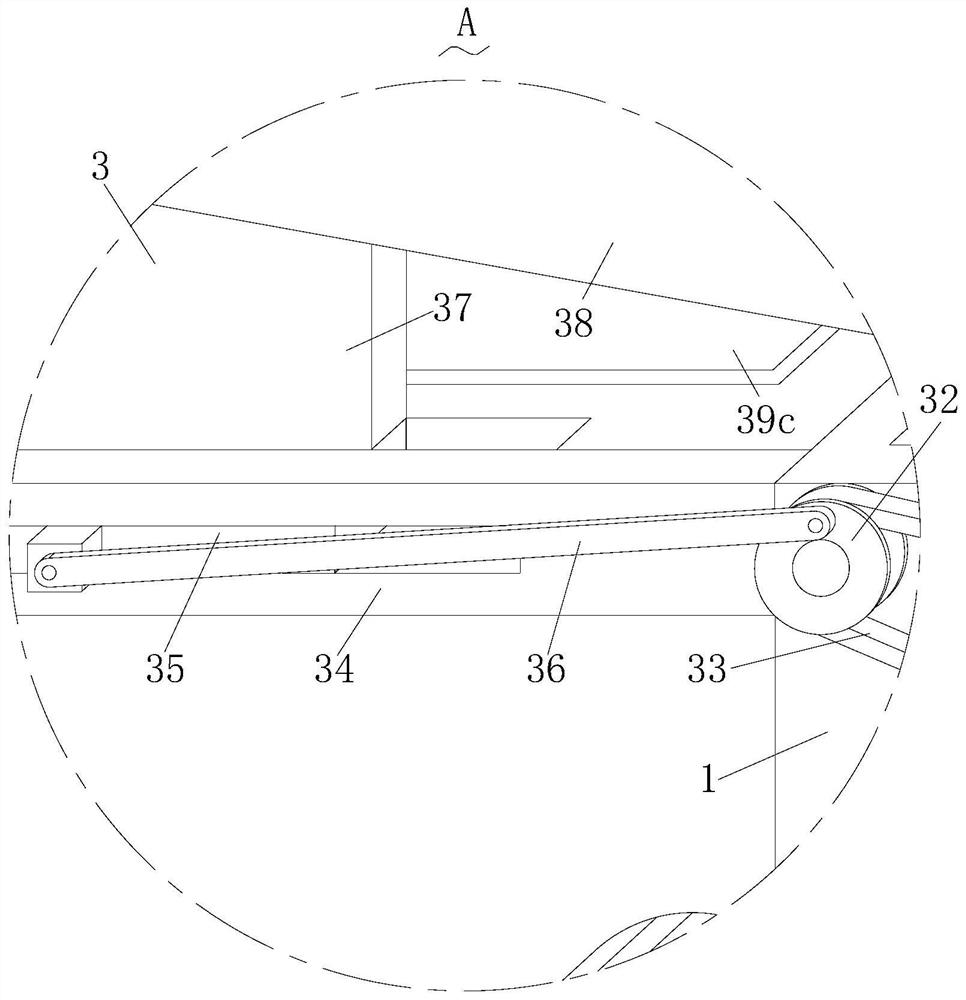

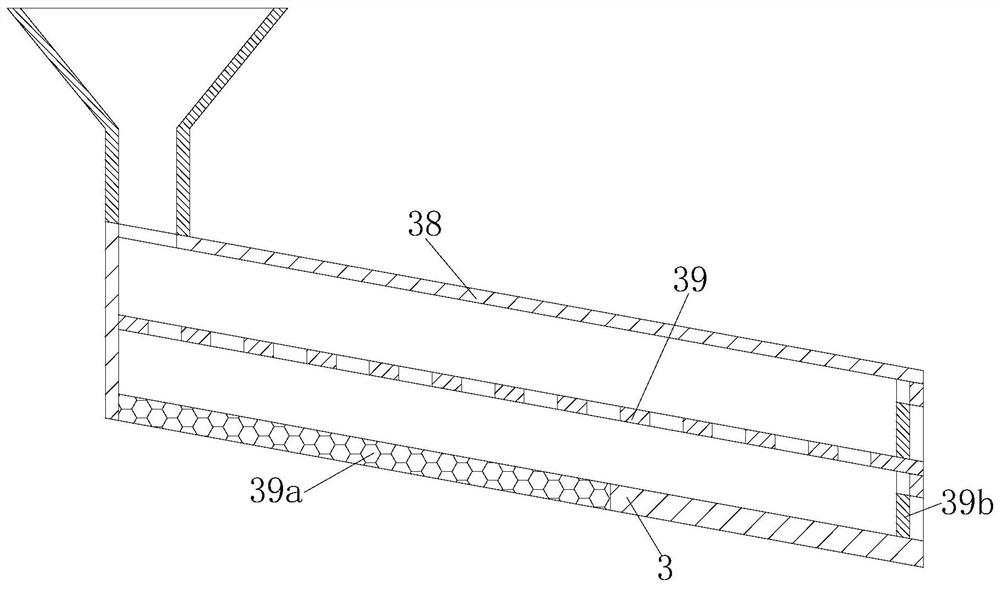

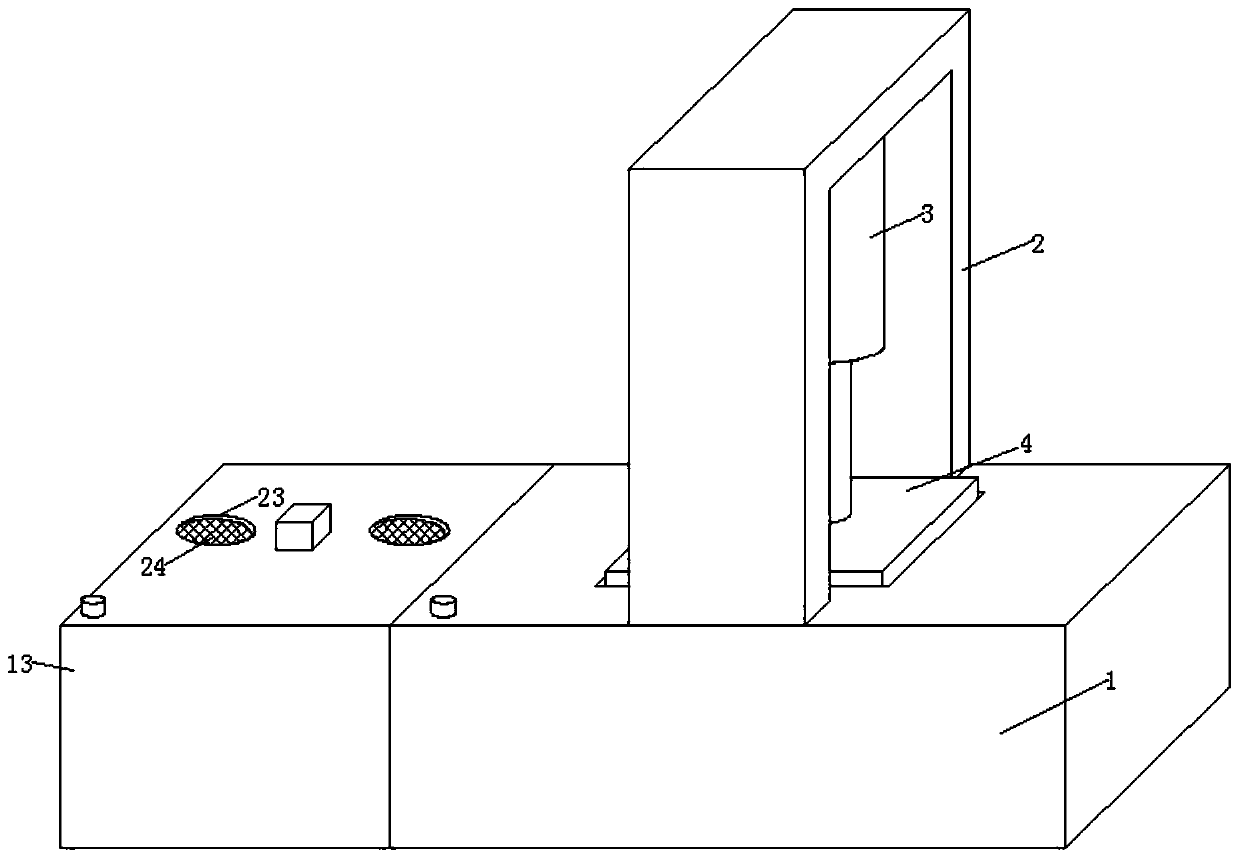

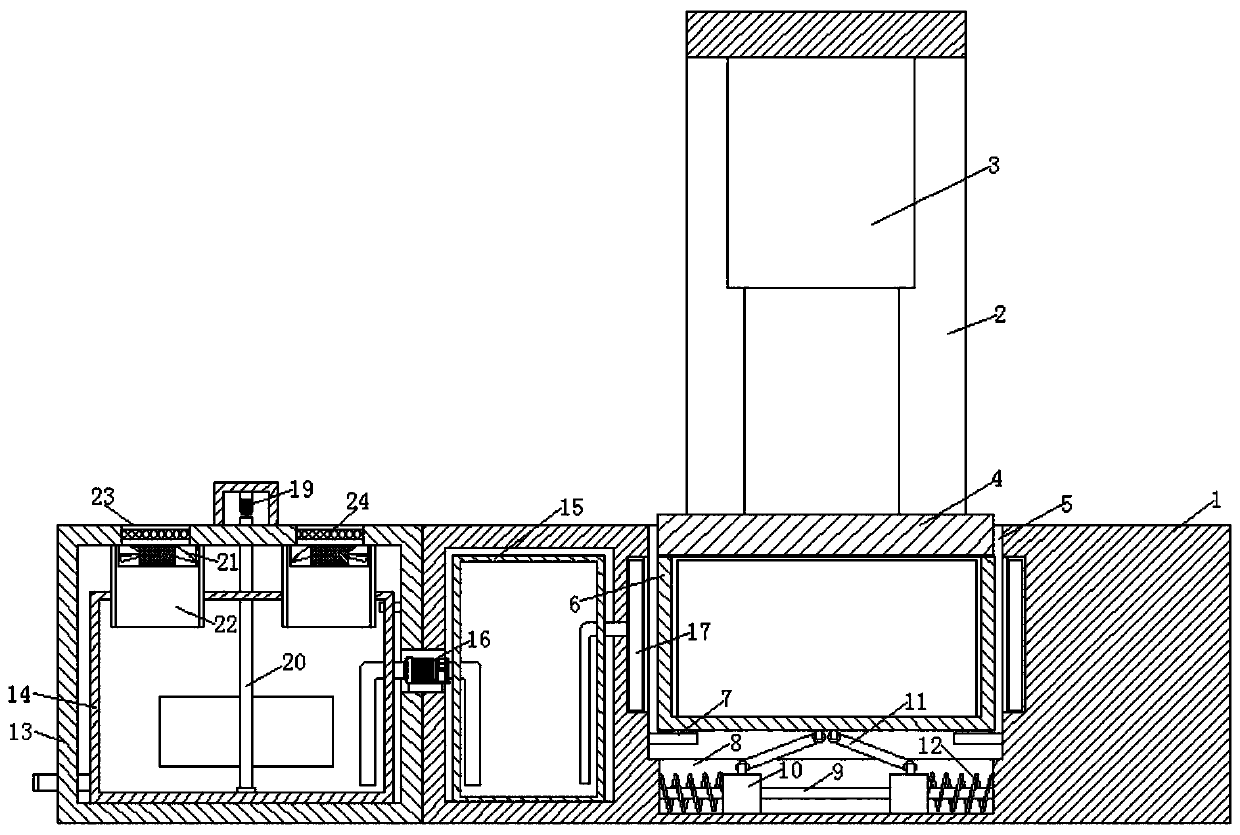

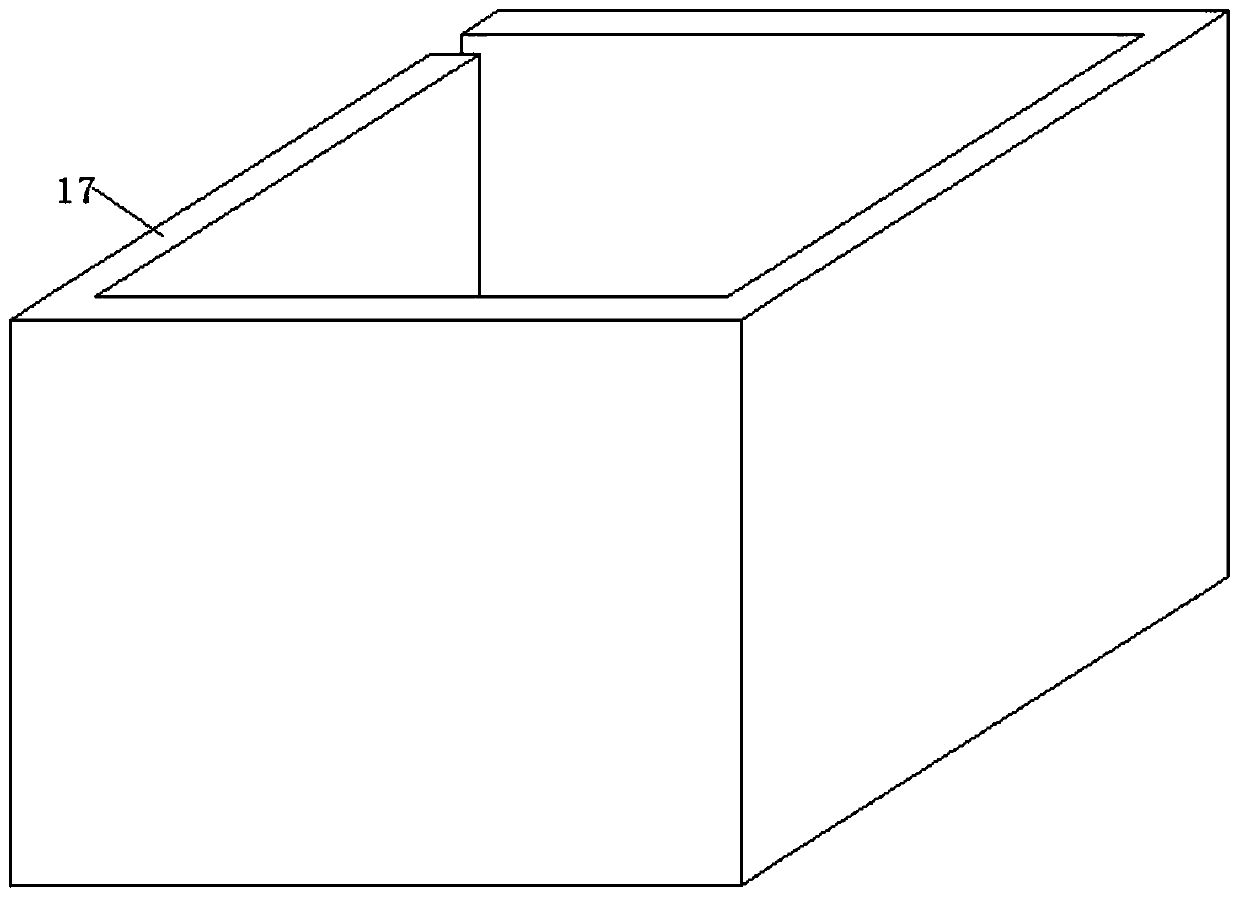

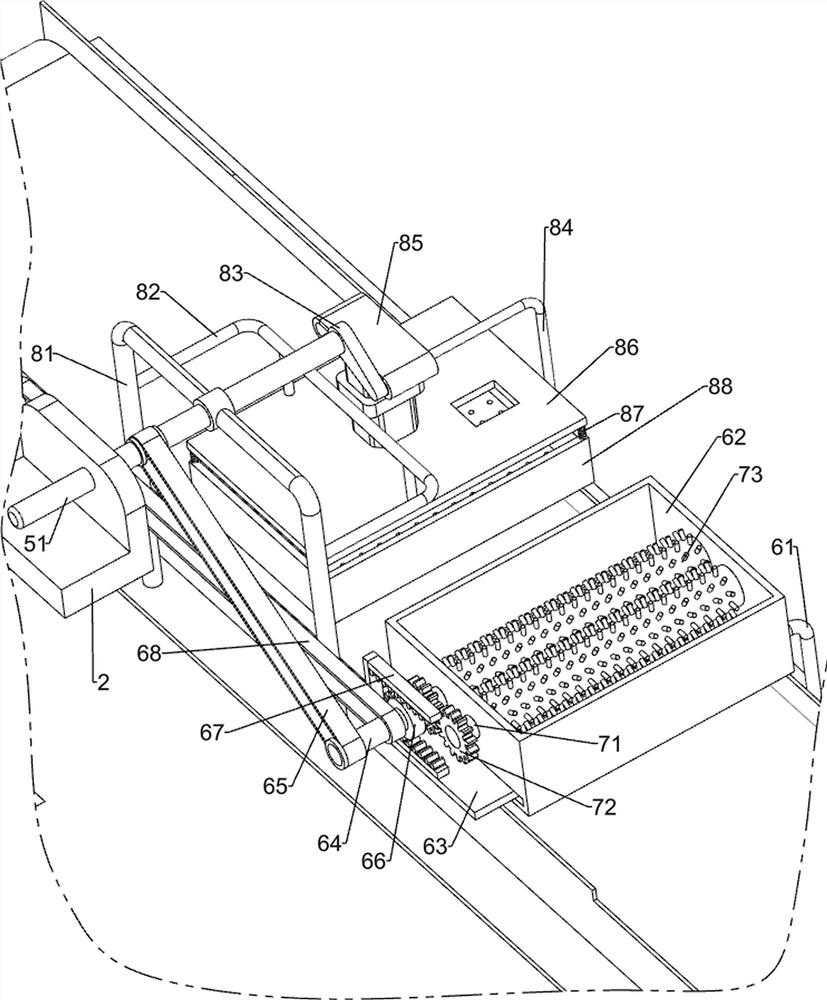

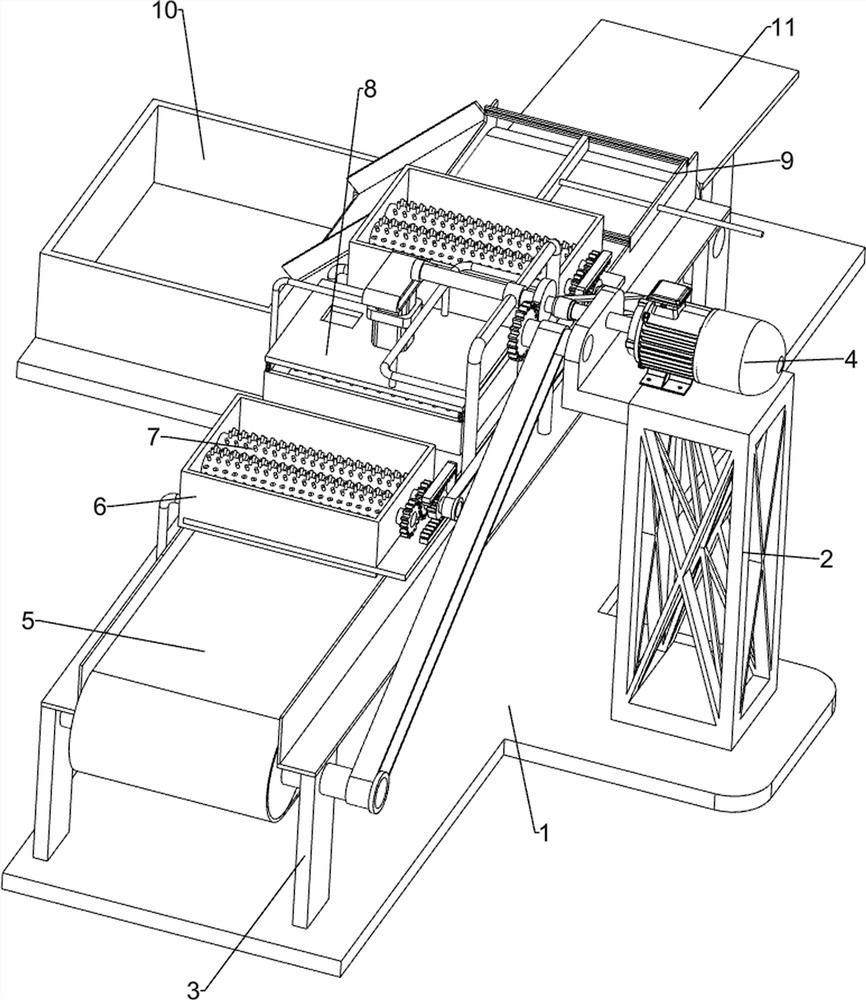

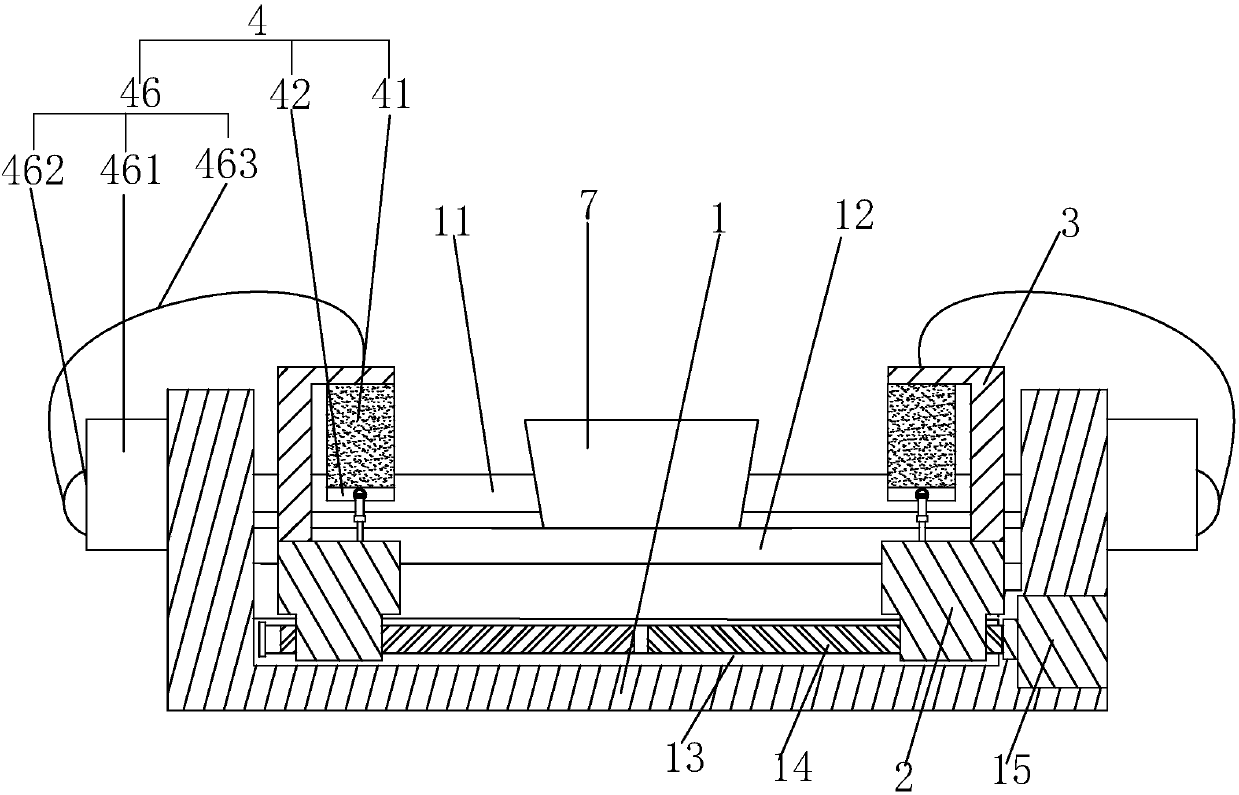

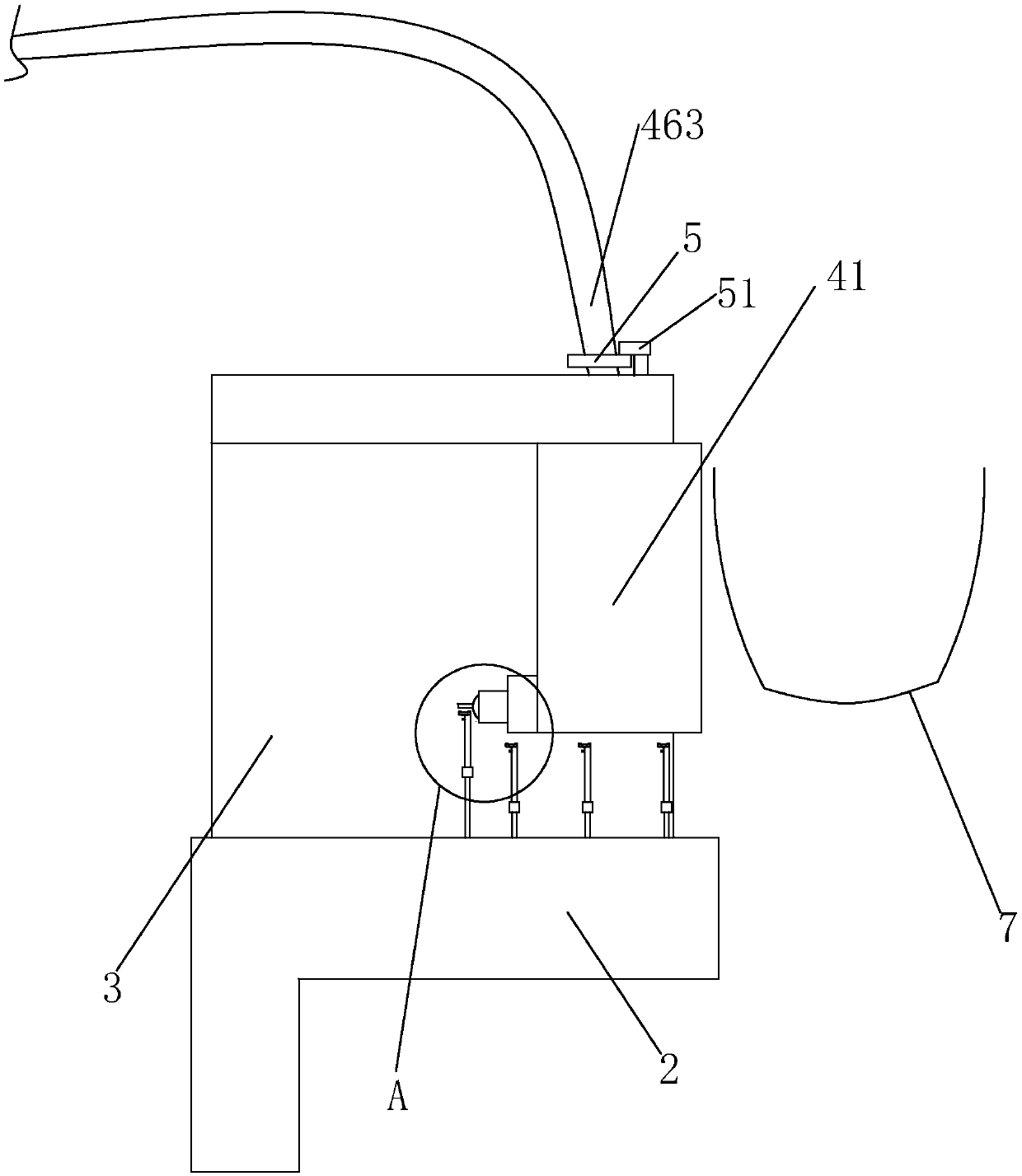

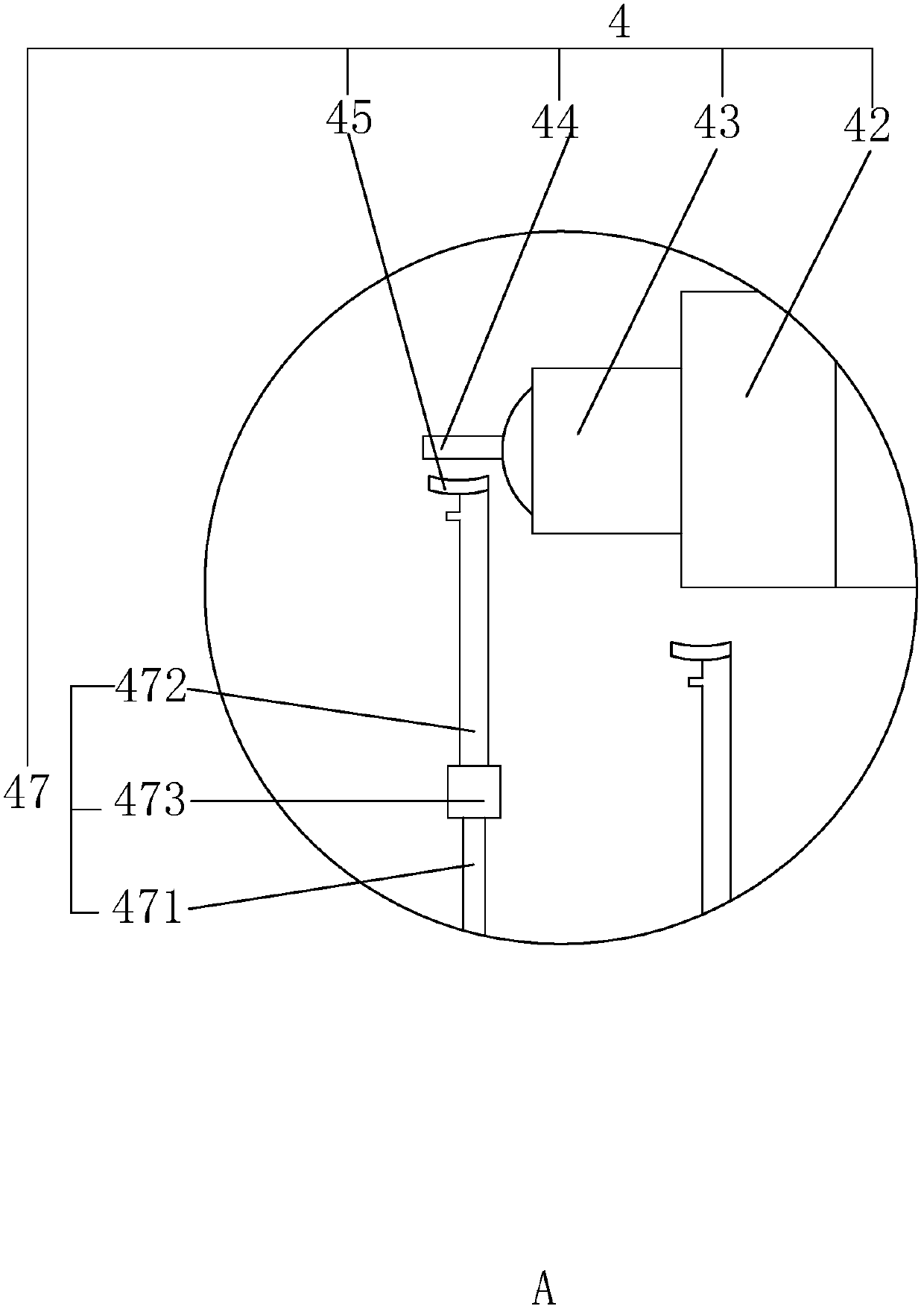

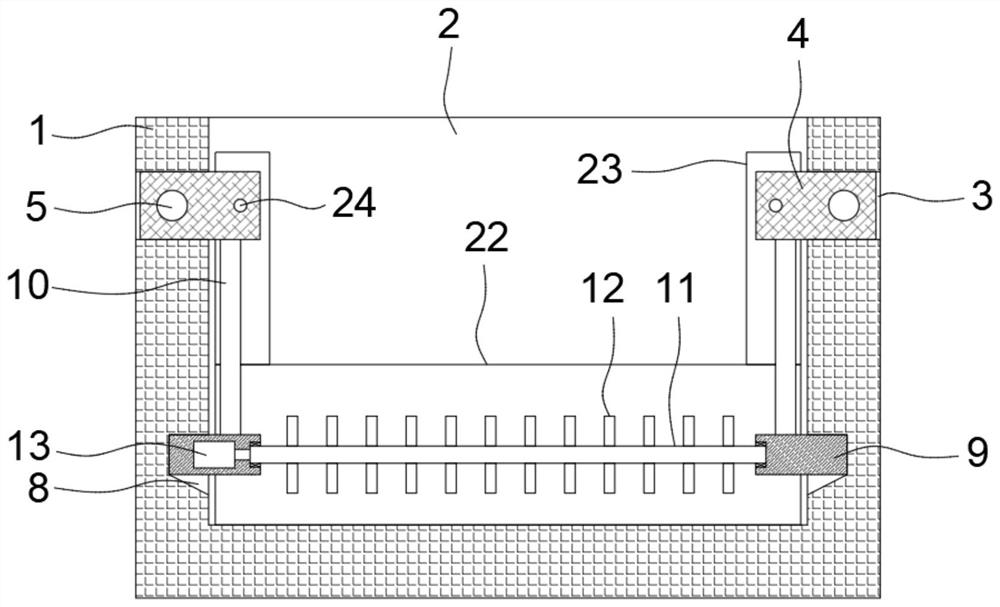

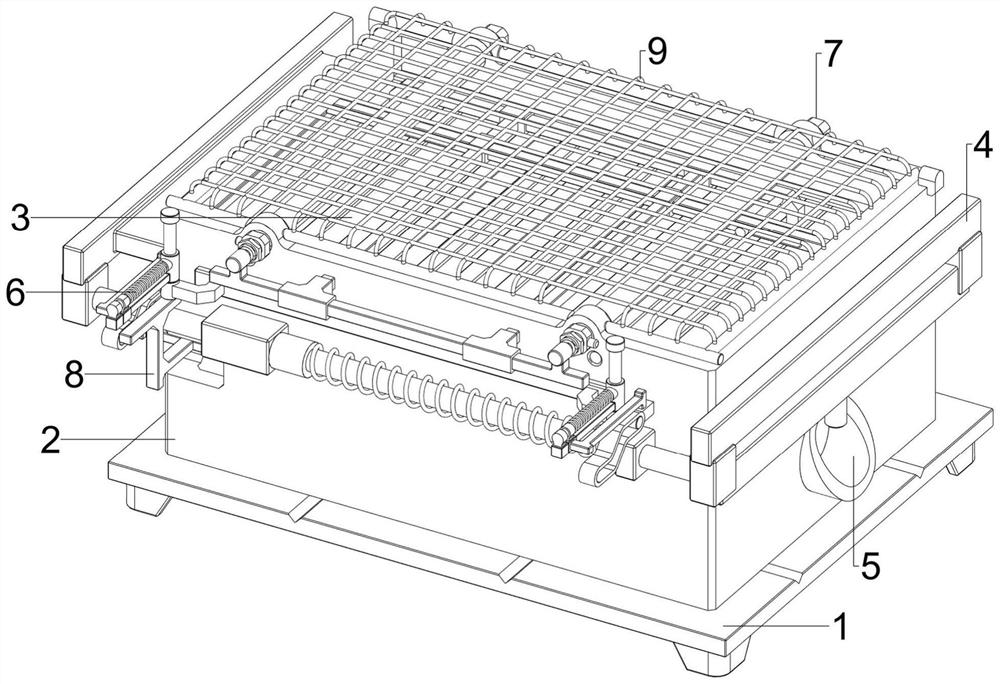

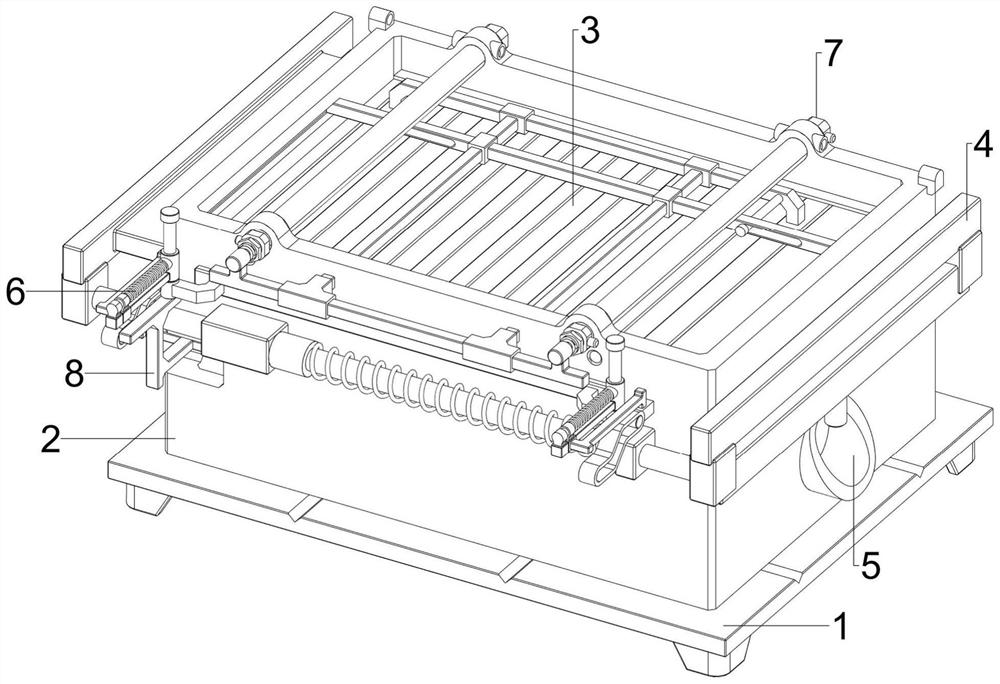

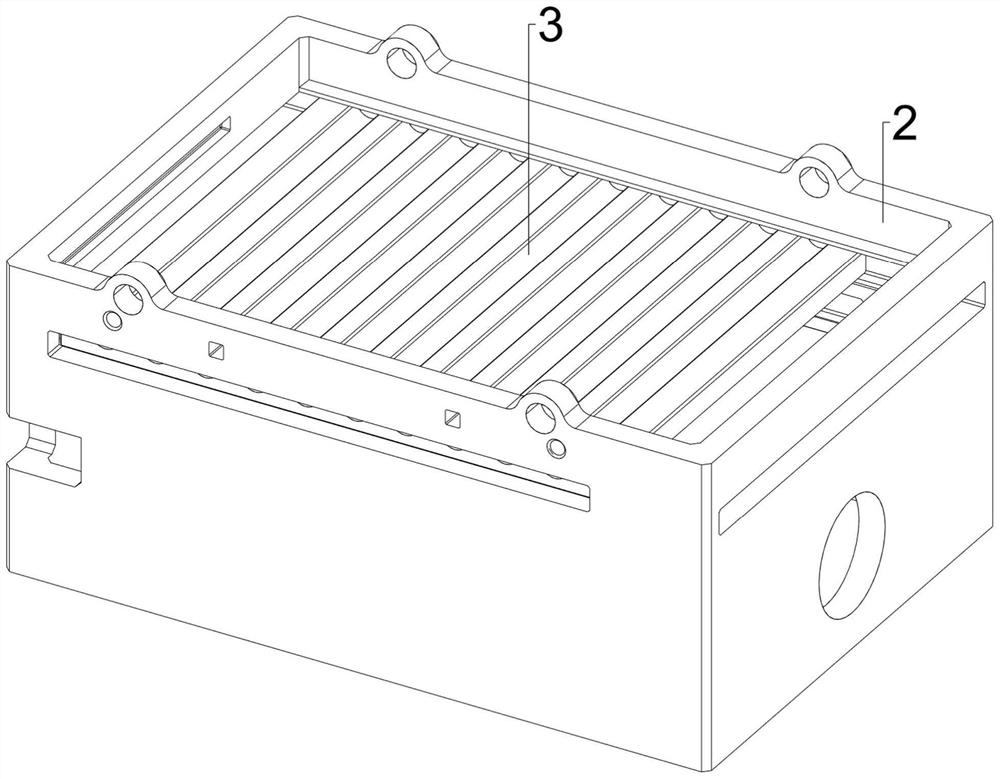

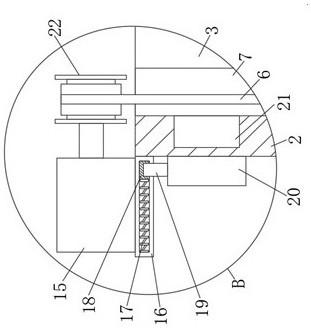

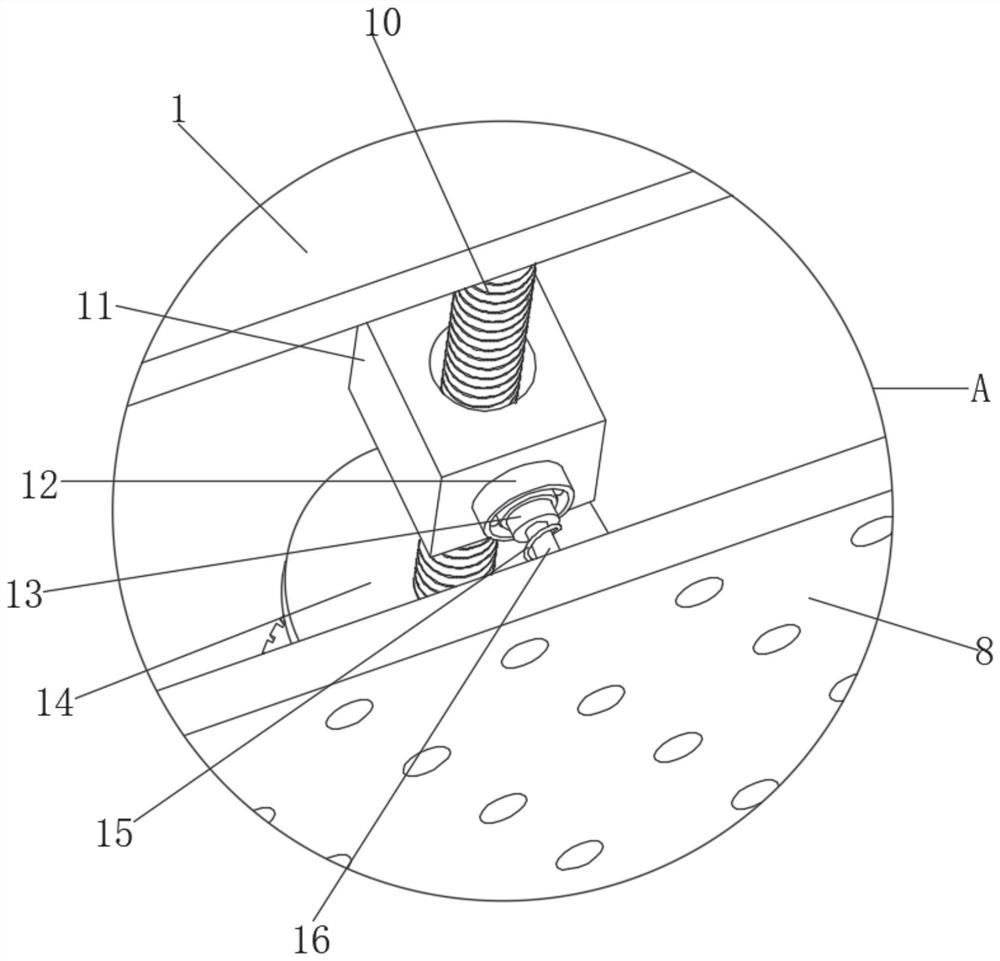

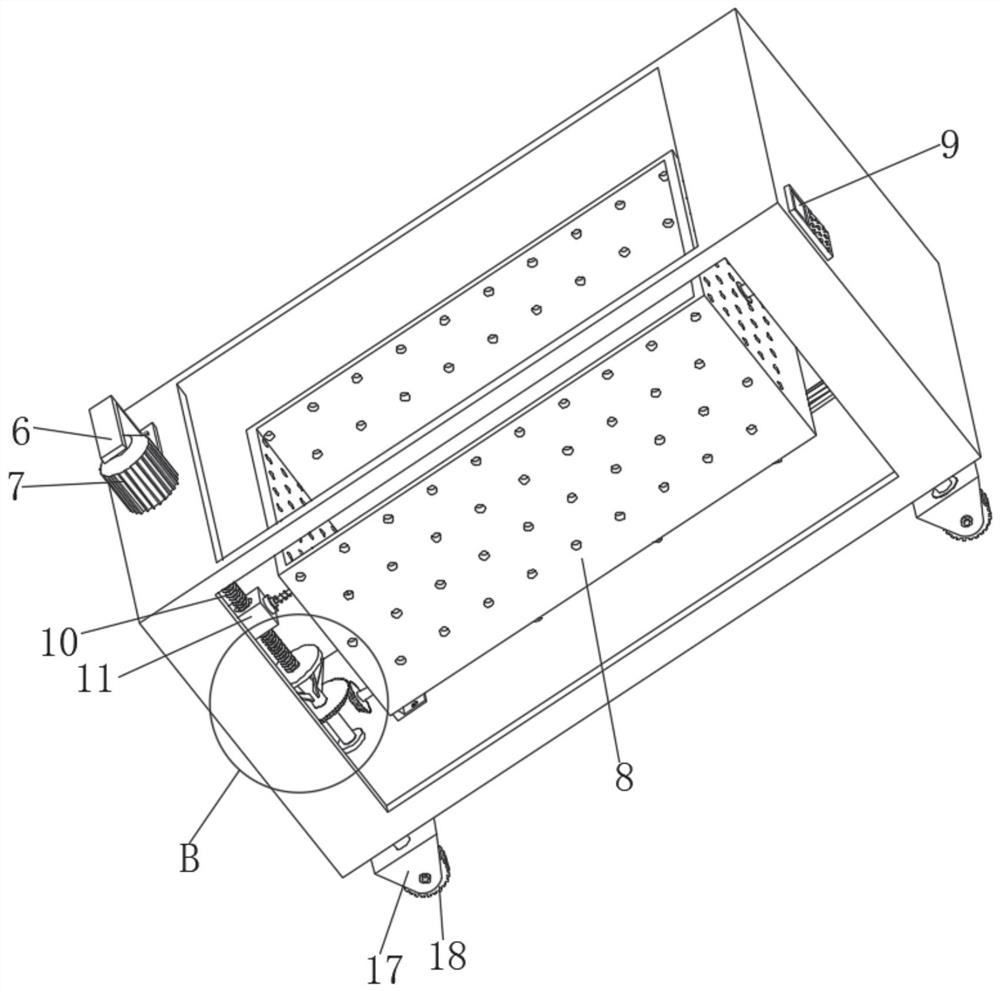

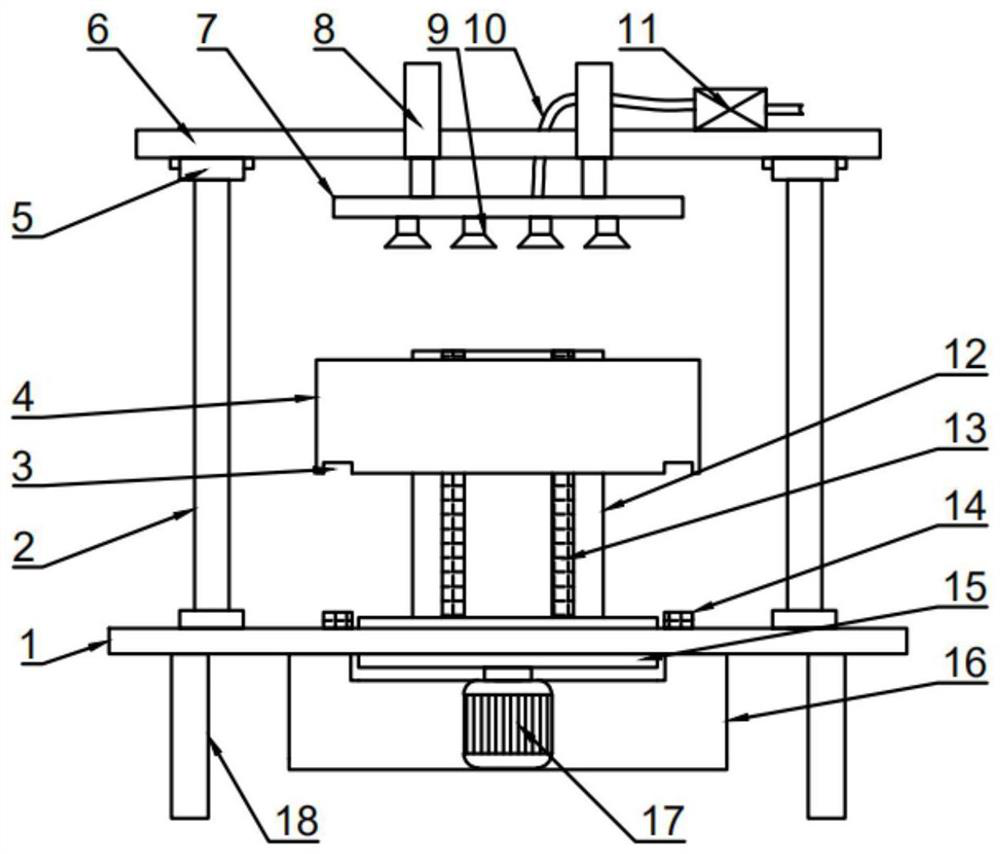

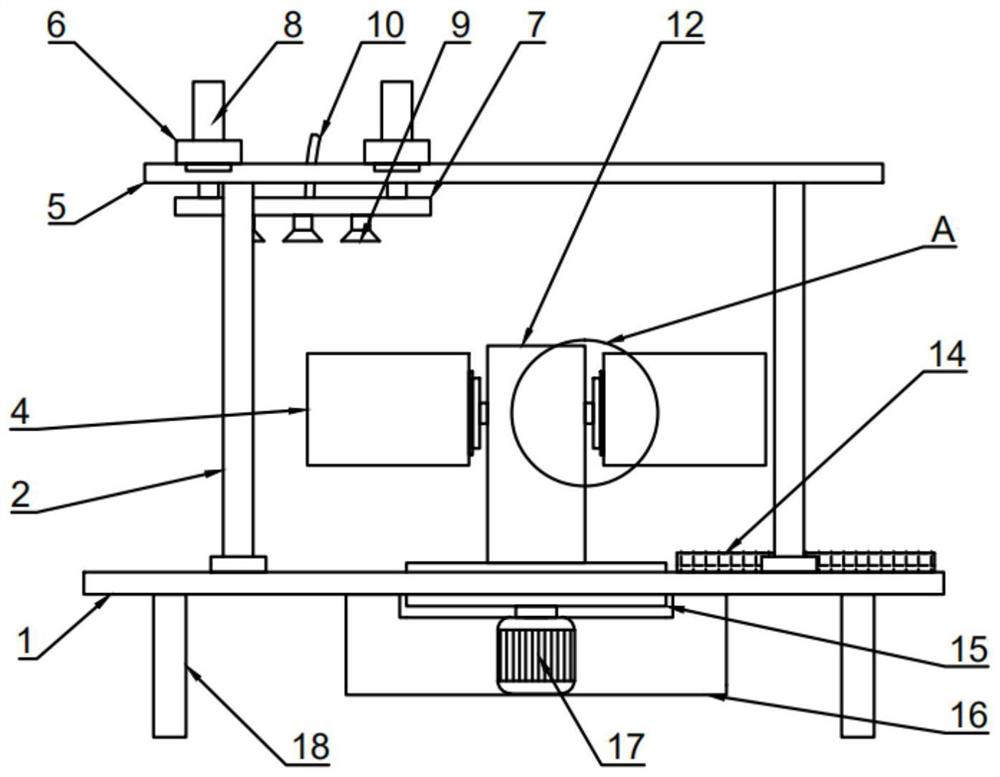

Seedling raising tray seeding equipment for agricultural seedling raising

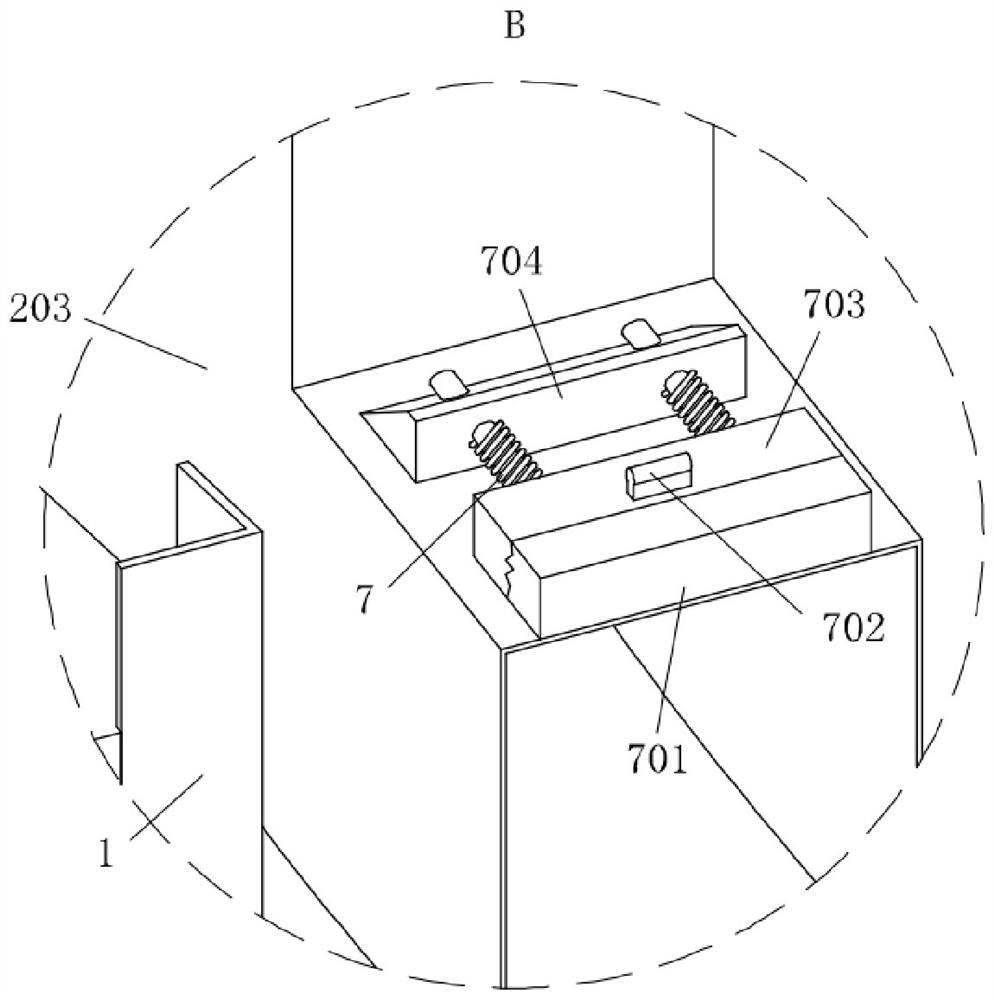

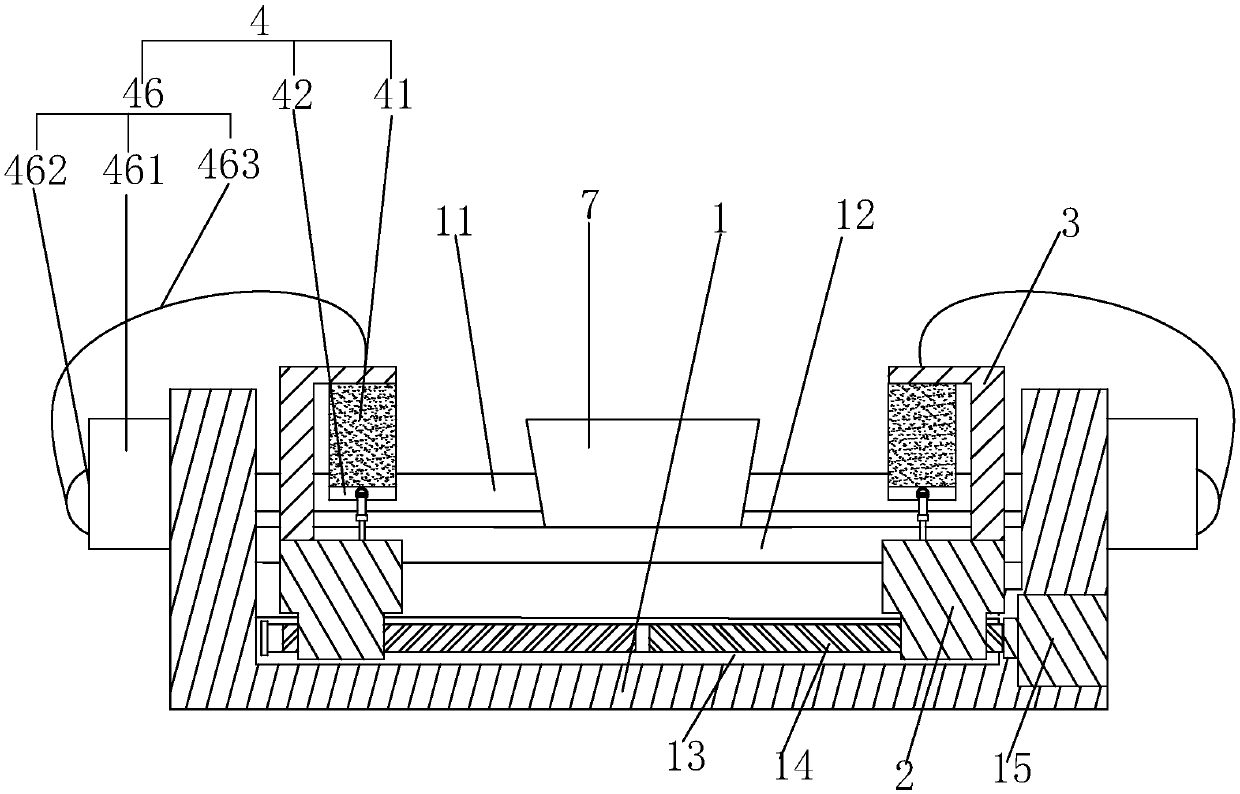

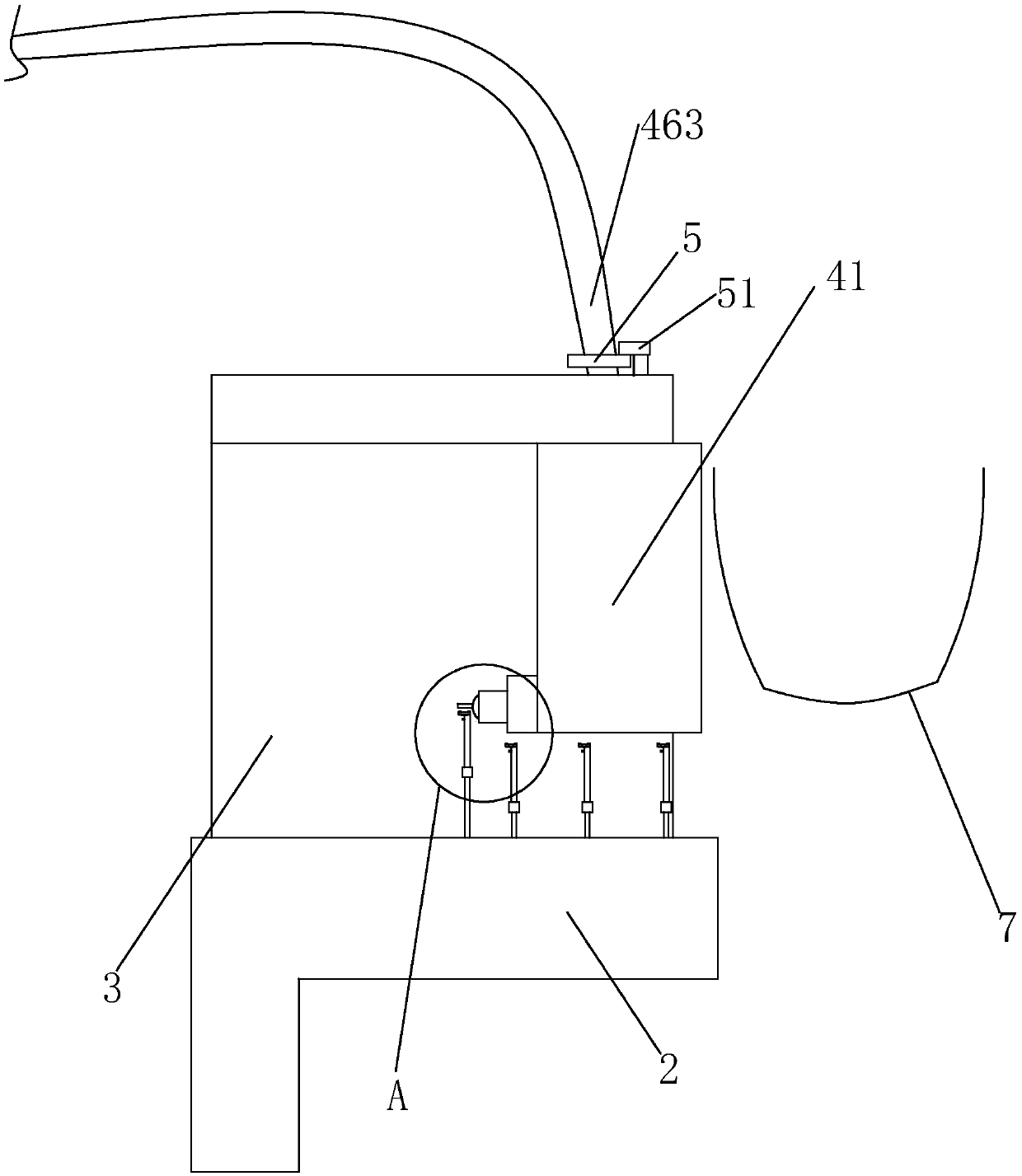

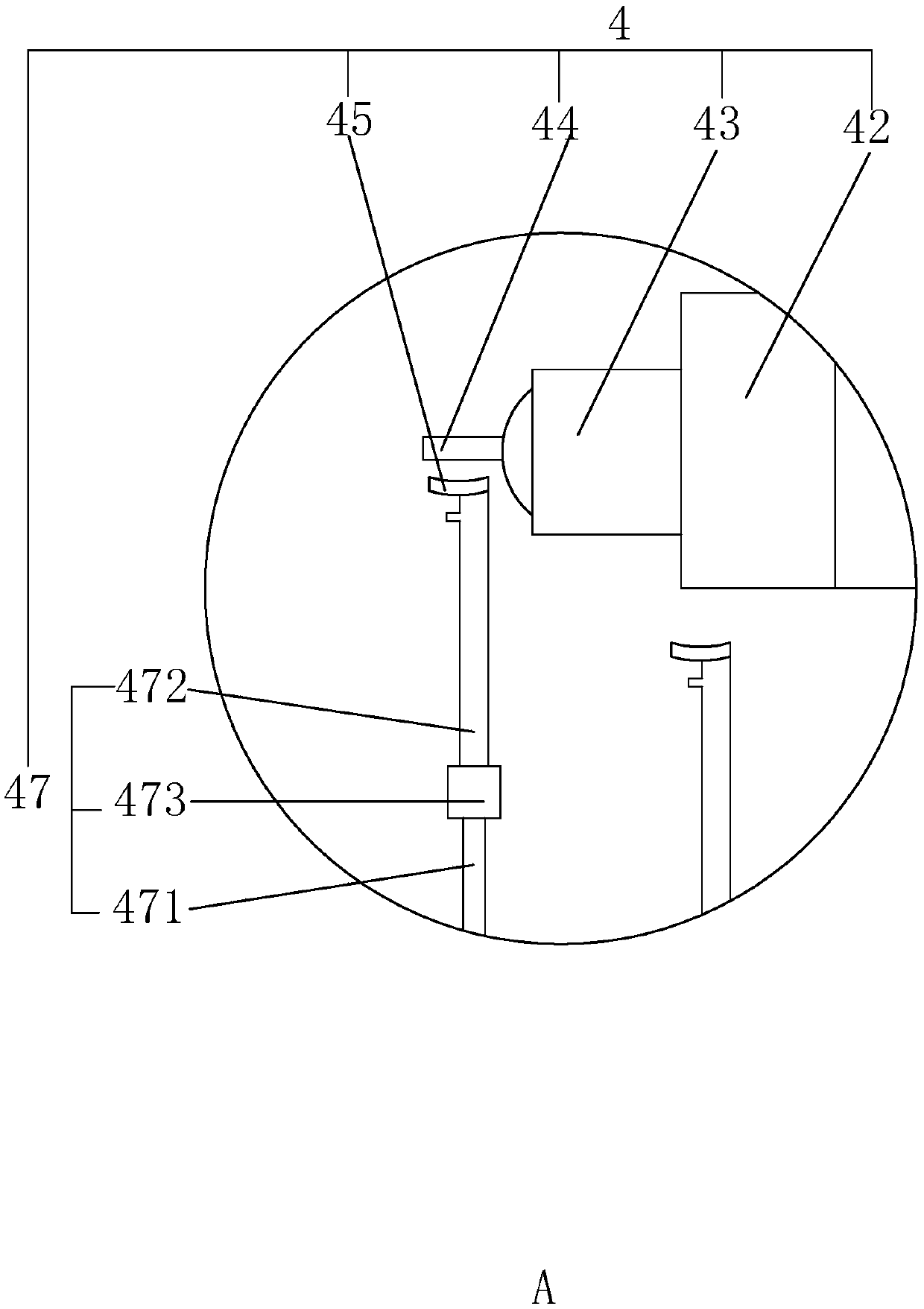

ActiveCN112616501ARealize semi-automatic seeding workLabor savingAgriculture gas emission reductionCultivating equipmentsAgricultural scienceAgricultural engineering

The invention relates to seedling raising tray seeding equipment, in particular to seedling raising tray seeding equipment for agricultural seedling raising. The technical problem to be solved is to provide the seedling raising tray seeding equipment for agricultural seedling raising, the operation process can be simplified, the waste of labor force is reduced, and the working efficiency is improved. In order to solve the technical problem, the seedling raising tray seeding equipment for agricultural seedling raising is provided and comprises a bottom plate, a supporting plate, a servo motor, a conveying mechanism and a discharging mechanism, wherein a placing frame is connected to the one side of the top of the bottom plate; the supporting plate is connected to the middle of the top of the bottom plate; the servo motor is connected to the placing frame; the conveying mechanism is connected between the placing frame and the supporting plate; the discharging mechanism is connected with the supporting plate. According to the seedling raising tray seeding equipment for agricultural seedling raising, through cooperation of the conveying mechanism and the discharging mechanism, semi-automatic seeding work can be realized, so that the labor force is saved, and the working efficiency is improved.

Owner:云南风沃农业科技有限公司

Oil immersing equipment for deep-frying yam starch wrapped beans

InactiveCN109329329AHigh degree of mechanizationEasy to transportDomestic stoves or rangesLighting and heating apparatusFixed frameDeep frying

The invention discloses oil immersing equipment for deep-frying yam starch wrapped beans. The oil immersing equipment comprises a fixing frame, wherein a source opening single-chip microcomputer, deep-frying pans, transporting mechanisms, lampblack sucking devices and collecting boxes are separately mounted on the fixing frame; a lifting mechanism is mounted at the bottom of each transporting mechanism; a stirring device is mounted at the bottom of each lifting mechanism; a string bag is connected to each lifting mechanism through a corresponding clamping mechanism; a drawing and pulling net plate is movably connected to the bottom of each string bag through a corresponding sliding mechanism; a handle is fixed to the side surface of each drawing and pulling net plate; and a heating deviceand a circulating filtering device are respectively mounted on the side surface of each deep-frying pan. According to the oil immersing equipment for deep-frying the yam starch wrapped beans disclosedby the invention, material bodies are put in the string bags, linear motors are controlled by the source opening single-chip microcomputer to work, and each linear motor moves on a corresponding annular guiding rail through a corresponding sliding block, so that each string bag transfers between the corresponding deep-frying pan and the corresponding collecting box, the oil immersing equipment disclosed by the invention is high in mechanized degree, convenient to transport and high in stability, and the processing efficiency is greatly improved.

Owner:ANHUI GUOSHUN CHINESE MEDICINE DEV CO LTD

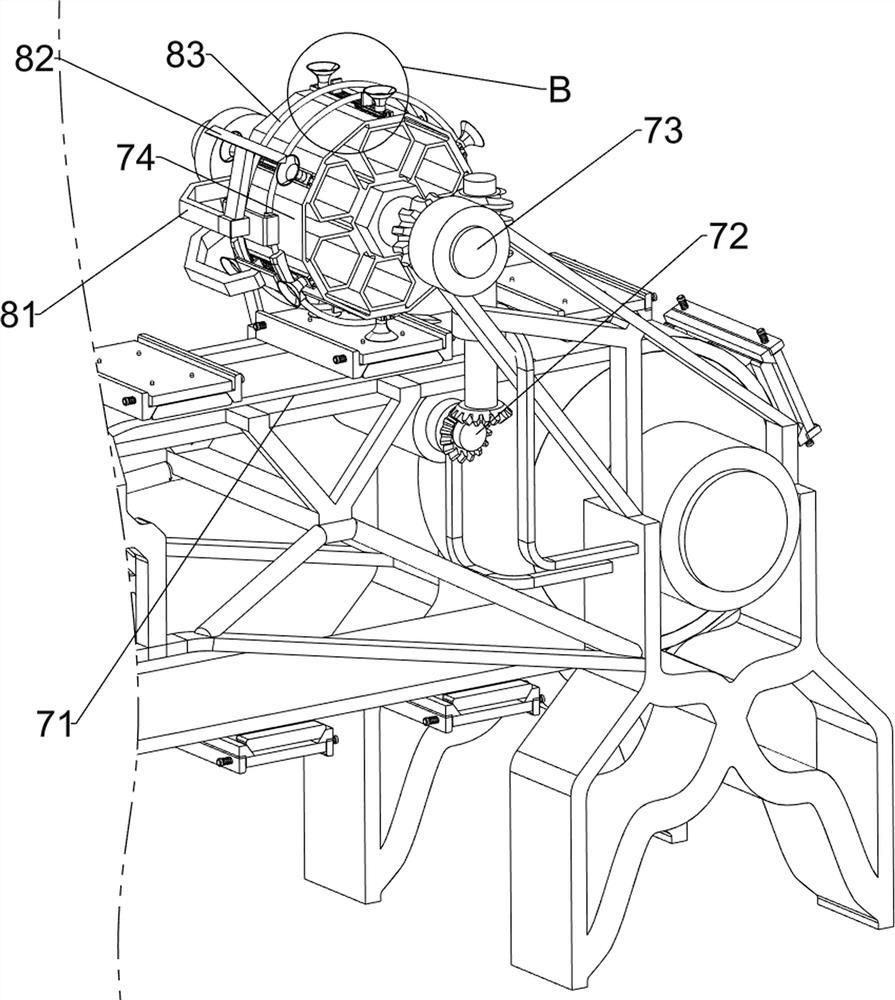

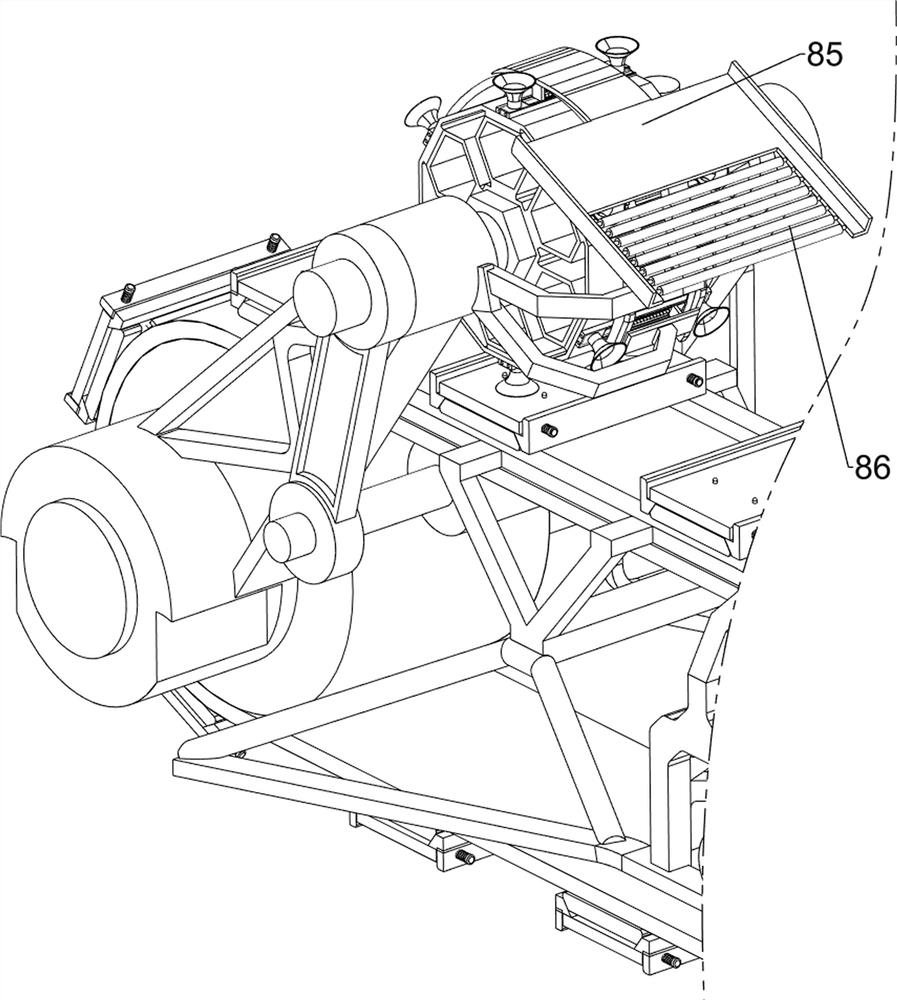

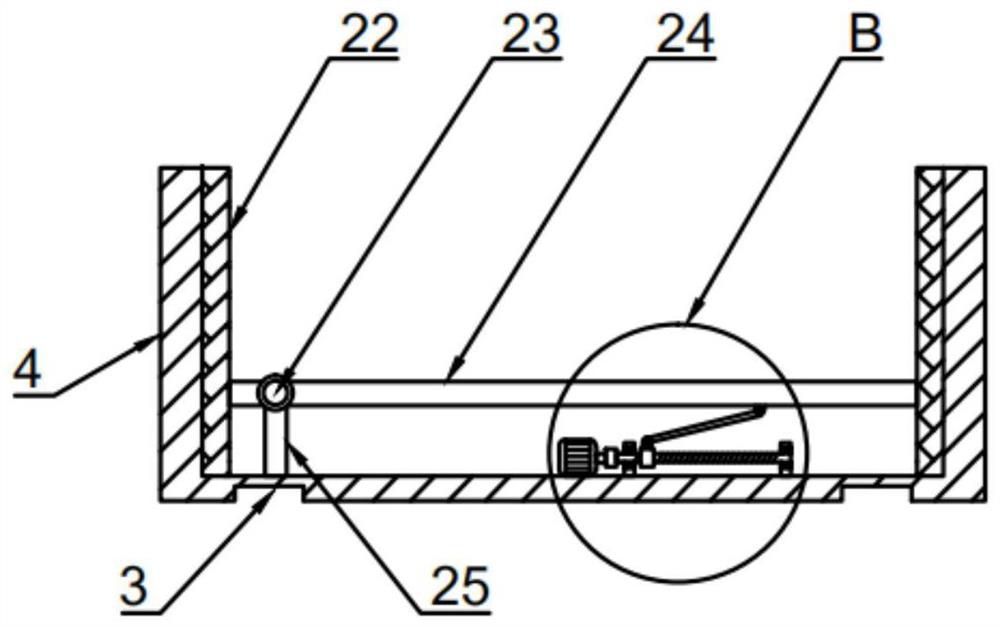

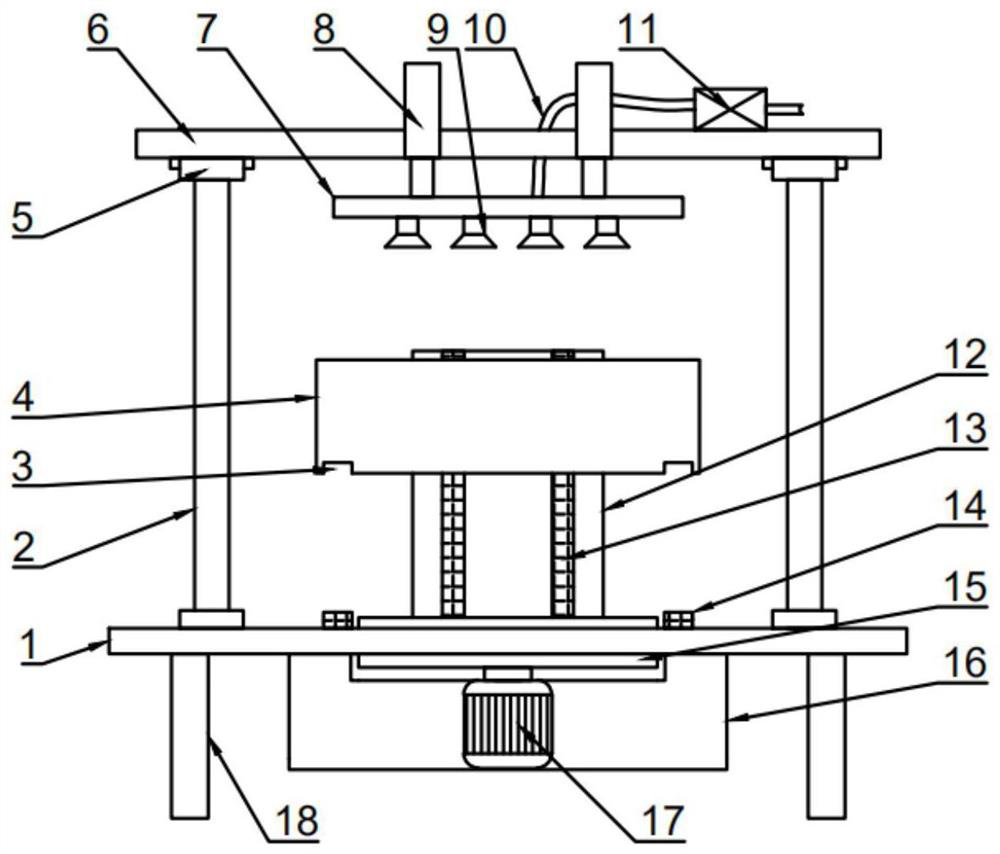

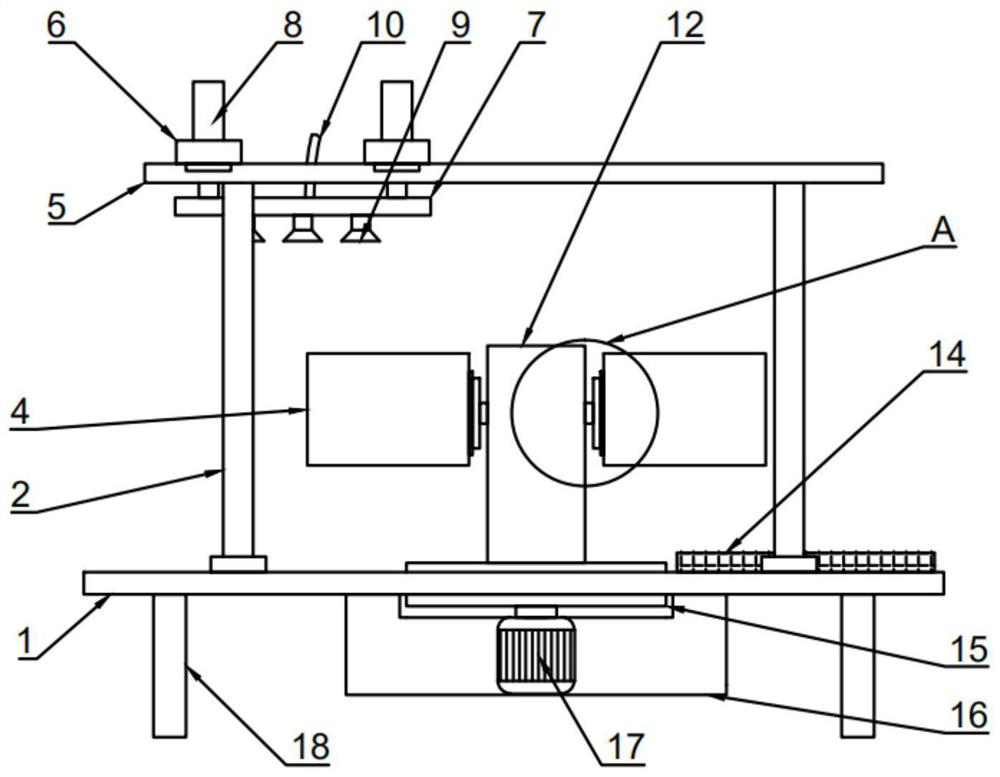

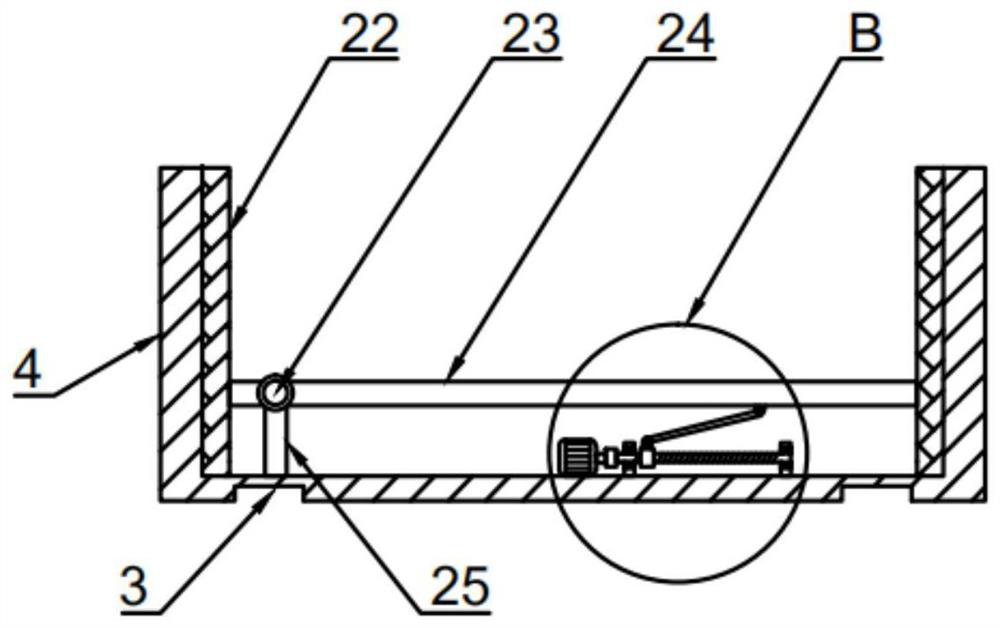

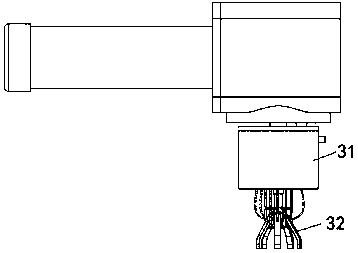

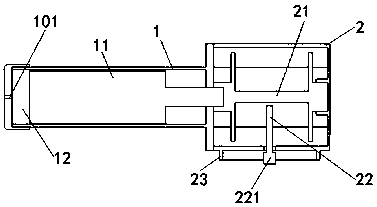

Combined veneer reeling machine

ActiveCN107855421ARapid cooling workConvenient pick-up workShaping toolsElectric machineryDrive motor

The invention discloses a combined veneer reeling machine. The combined veneer reeling machine comprises a rack, an upper roller and a lower roller, wherein a guide rail parallel to the upper roller is arranged on the rack, and a working screw rod connected with a driving motor is arranged in the guide rail; the two ends of the working screw rod are both in threaded connection with a sliding block, the two sliding blocks can move face to face or oppositely, and a supporting frame is fixedly arranged on each sliding block; each supporting frame is provided with a cooling device. Each cooling device comprises a sponge mat arranged on the corresponding supporting frame, wherein the top of the sponge mat is fixedly connected with the supporting frame, a connecting piece is fixedly arranged atthe bottom of the sponge mat, and a connecting ring is arranged on the connecting piece. A plurality of positioning hooks for the connecting rings to sleeve are arranged on the sliding blocks, the positioning hooks are sequentially arrayed on the sliding blocks from low to high, and a water outlet mechanism which is communicated with the sponge mats is arranged on the rack. The combined veneer reeling machine is additionally provided with the cooling devices for reeled veneers so that working personnel can conveniently take materials and work, work accidents can be reduced and the working efficiency can be improved.

Owner:JIANGSU MINGYU NEW ENERGY RESOURCES

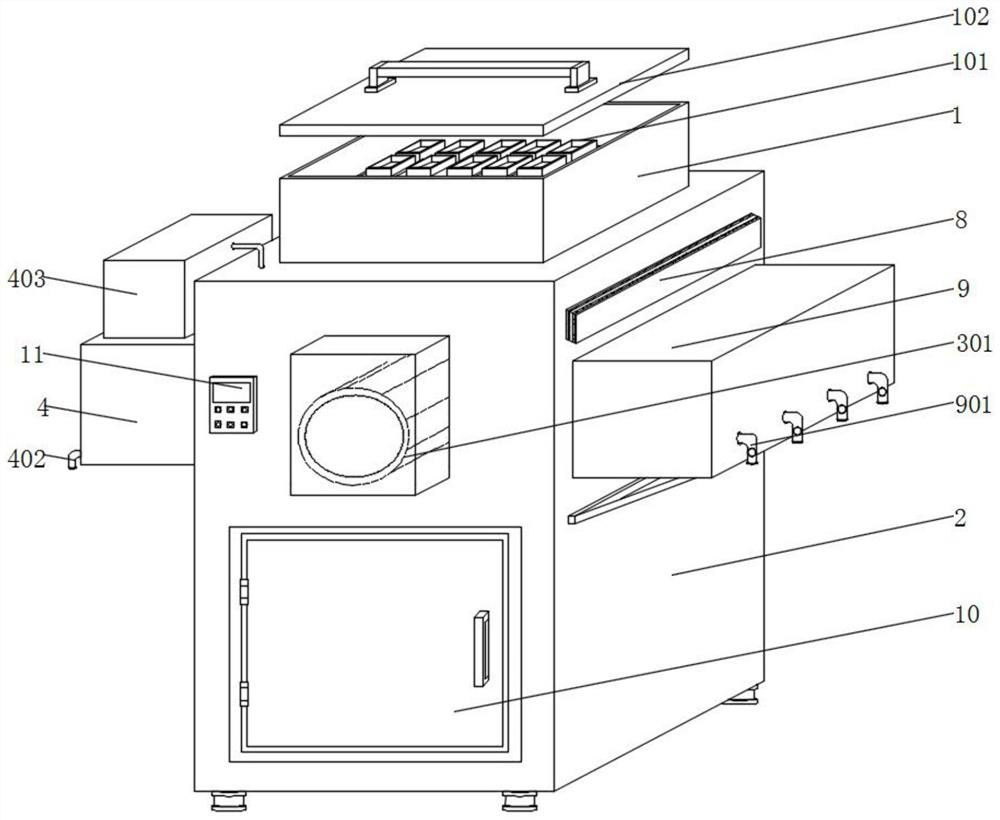

Distributing and mixing integrated machine with crushing structure and for food additives

InactiveCN112547254AConvenient pick-up workReduce bending timesTransportation and packagingMixer accessoriesFood additiveEngineering

The invention discloses a distributing and mixing integrated machine with a crushing structure and for food additives. The distributing and mixing integrated machine with the crushing structure and for food additives comprises a feeding box, a centrifugal rotary drum and a feeding pipe, the feeding box is installed at the top of a machine body, a driving cutting roller and a driven cutting rollerare installed on the inner wall of the front face of the machine body through bearings, a stirring and mixing cylinder is installed on the inner wall of the machine body through a connecting rod, thecentrifugal rotary drum is installed in the stirring and mixing cylinder, the feeding pipe is installed on the inner wall of one side of the machine body through a fixing ring, a liquid discharging box is fixed to the outer wall of one side of the machine body, a solid discharging box is fixed to the outer wall of the other side of the machine body, a heat dissipation ventilation plate is installed on the outer wall of the other side of the machine body, a machine door and a controller are installed on the front face of the machine body, and the controller is located above the side of the machine door. By arranging a series of assemblies, the machine can lift processed materials, so that a worker does not need to bend down during material taking, and material taking is facilitated.

Owner:海安市弘华生物科技有限公司

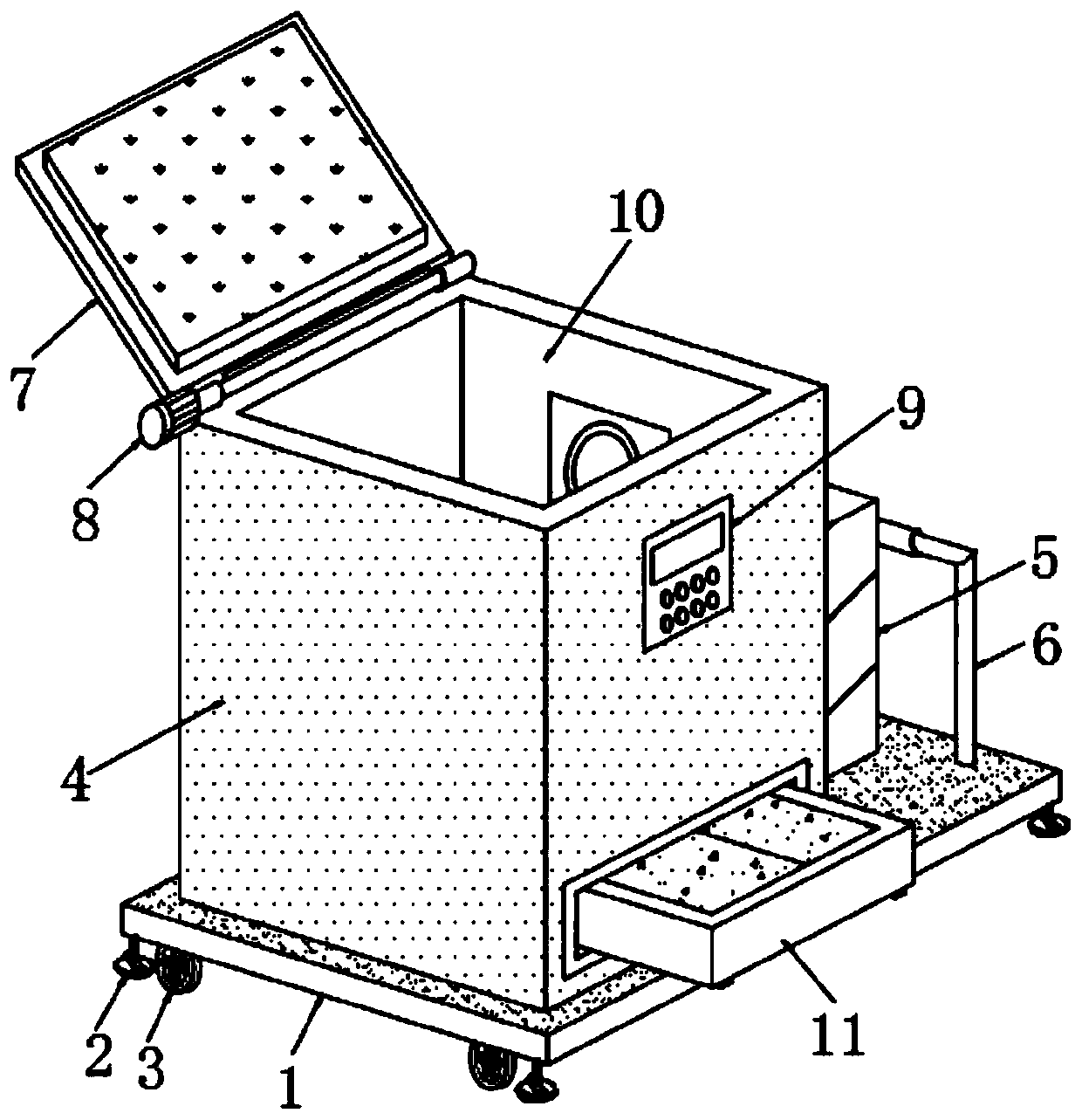

Raw material storage device for nanocrystal preparation and use method

InactiveCN110733770AAchieve rotationAuto openDispersed particle filtrationLarge containersProcess engineeringNanocrystal

The invention discloses a raw material storage device for nanocrystal preparation and a use method, and relates to the technical field of nanocrystal preparation. The raw material storage device comprises a base, wherein supporting legs are fixedly arranged on the lower surface of the base, and the lower surface of the base is provided with universal wheels at the inner side positions of the supporting legs; and a box body is fixedly arranged on the upper surface of the base, and the upper surface of the base is fixedly provided with a ventilation mechanism at one side position of the box body. The raw material storage device for the nanocrystal preparation is scientific and reasonable in structure and convenient to use and operate; through the arrangement of a cover opening mechanism, thepurpose of automatic opening and closing of a box cover can be achieved, and convenience is provided for storage work of nanocrystal raw materials; through the arrangement of a material storage mechanism, the adjustment of discharge flow can be realized, convenience is provided for the material taking work by a worker; and through the arrangement of a discharging mechanism, automatic dischargingwork of the raw materials can be achieved, the material taking work by the worker is facilitated, manpower is effectively saved, and working efficiency is improved.

Owner:南京纳希纳米科技有限公司

Self-flowing type closed automatic production device for refractory castable

InactiveCN111921427AConvenience for pouring workSimple and convenient temperature control workRotating receptacle mixersTransportation and packagingRefractoryProcess engineering

The invention discloses a self-flowing type closed automatic production device for refractory castable. The self-flowing type closed automatic production device comprises a working box; a rotating hole is formed in the working box; a discharging pipe is rotationally connected into the rotating hole; a discharging box is fixedly connected to the upper end face of the discharging pipe. The end, awayfrom the discharging pipe, of the discharging box is fixedly connected with a rotating box. And the rotating box is rotatably connected into the working box, the rotating box, the discharging box andthe discharging pipe are arranged in a communicating mode, a discharging device is arranged on the discharging pipe, a plurality of clamping grooves formed at equal intervals are formed in the side wall, away from the rotating hole, of the working box, and clamping blocks are slidably connected into the clamping grooves. According to the water adding device, the product production temperature iseffectively controlled, the uniformity of water adding work is guaranteed, the product production quality is greatly improved, and great convenience is brought to a user to conduct product dischargingand pouring work.

Owner:郑州博达耐火材料有限公司

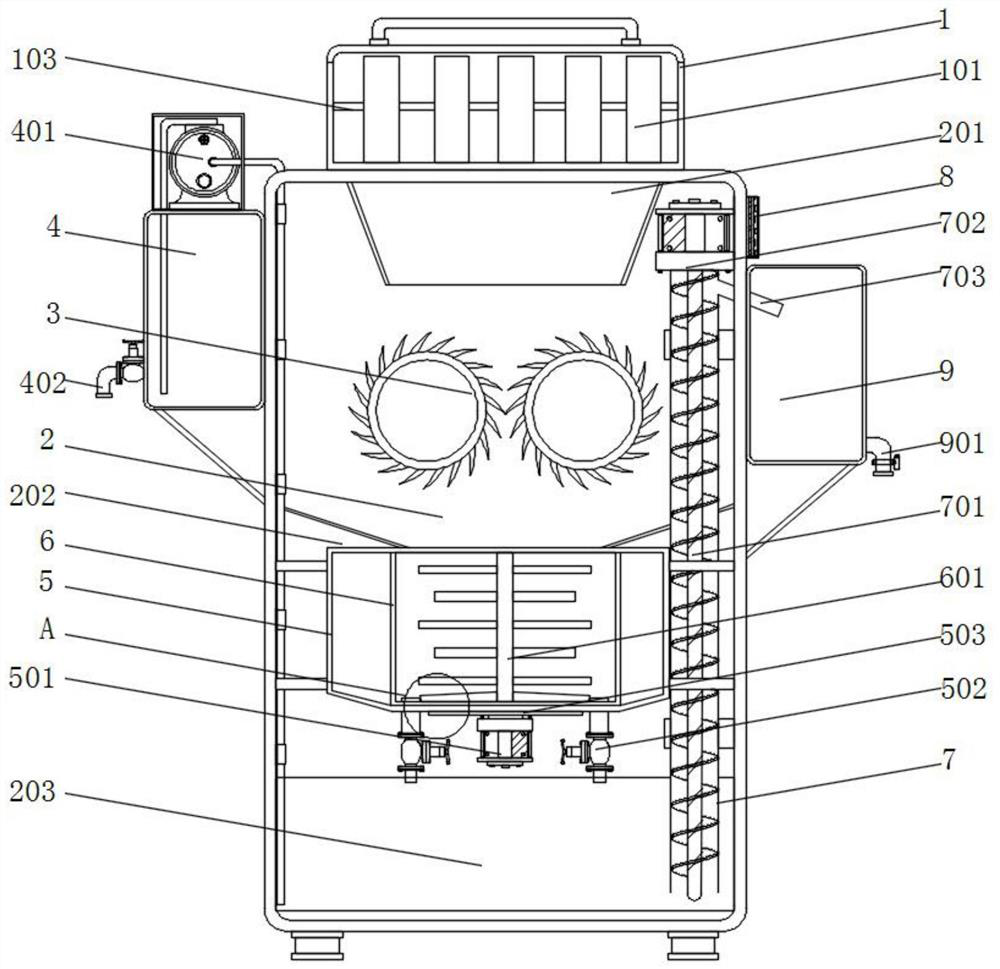

Fish feed production fermentation and material taking device

InactiveCN113355213AEvenly distributedNo stack bumpsBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringScrew thread

The invention discloses a fish feed production fermentation and material taking device which comprises a fermentation box. The fermentation box is provided with a fermentation tank; sliding openings are longitudinally formed at the positions, close to an opening of the fermentation tank, of the inner walls of the left side and the right side of the fermentation tank; two-way threaded rods are jointly and rotationally connected between the front inner walls and the rear inner walls of the two sliding openings; the two two-way threaded rods are correspondingly sleeved with two first moving blocks which are symmetric front and back about the central sections of the two-way threaded rods in a threaded mode; chutes which are parallel to the sliding openings at the upper portion and are equal in length are formed at the positions, close to the inner bottom wall of the fermentation tank, of the inner walls of the left side and the right side of the fermentation tank; and two second moving blocks are slidably connected into each of the two chutes; and the eight second moving blocks correspond to the eight first moving blocks above in position. The fish feed production fermentation and material taking device has the advantages that the fish feed production fermentation and material taking device is high in automation degree, a fish feed does not need to be manually stirred and taken, fish feed residues cannot be caused in the taking process, and the fermentation and taking efficiency of the fish feed is improved.

Owner:福建大昌盛饲料有限公司

An Efficient Bridge Equipment

ActiveCN108103958BEasy to fall intoPrevent fallingBridge structural detailsBridge erection/assemblySlide plateThreaded rod

The invention relates to efficient bridge equipment. The bridge equipment includes a containing tank, a handcart is fixedly arranged at the bottom of the containing tank, and rolling wheels are simultaneously arranged at four corners of the bottom of the handcart. The containing tank is provided with a containing chamber with an opening facing upwards and a sliding groove with an opening facing rightwards, a cover body is mounted at the upper end of the containing chamber, a discharging opening is formed between the containing chamber and the sliding groove, a sliding piece is slidingly installed in the sliding groove, and a containing groove with an opening facing upwards is formed in the sliding piece. A straight plate extending rightwards is disposed at the right end of the bottom wallof the sliding groove, a first sliding groove with an opening facing upwards is formed in the bottom wall of the sliding groove and the straight plate, a first sliding block is slidingly installed inthe first sliding groove, and a threaded rod is cooperatively installed in the first sliding block through threads. The right end of the threaded rod is rotatably installed in the right end wall of the first sliding groove, the left end of the threaded rod is connected with a motor fixedly installed in the left end wall of the first sliding groove, a guide moving groove extending horizontally is formed in the front and rear end walls of the discharging opening, and a sliding plate extending in the front and back directions is slidingly installed in the guide moving groove.

Owner:泉州旗信专利技术咨询有限公司

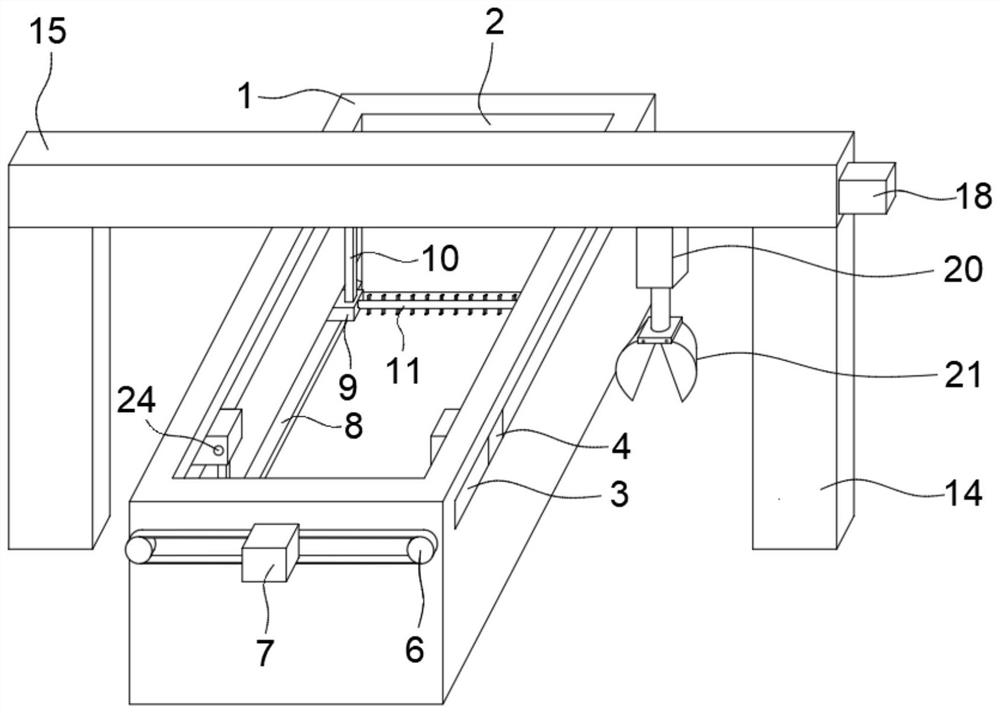

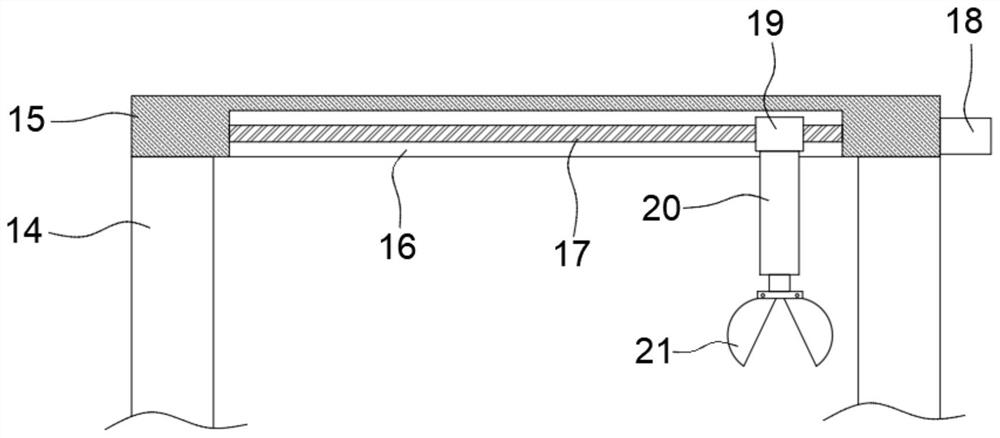

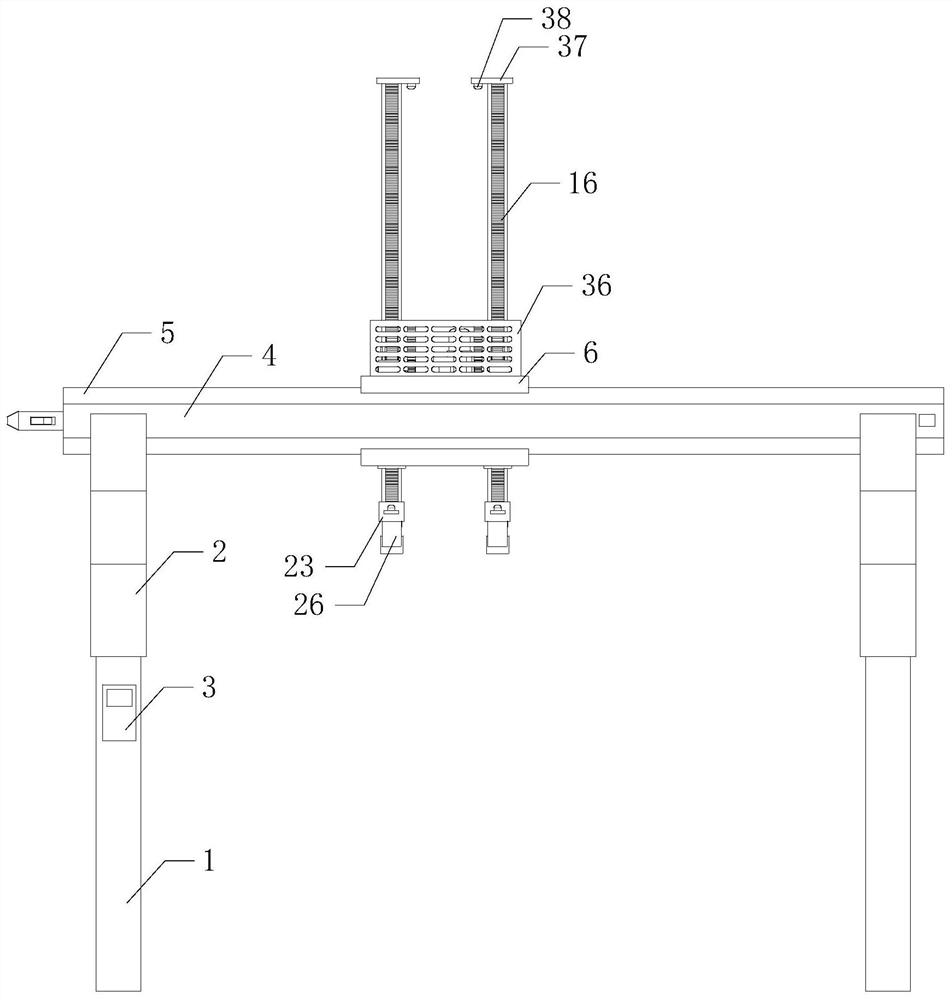

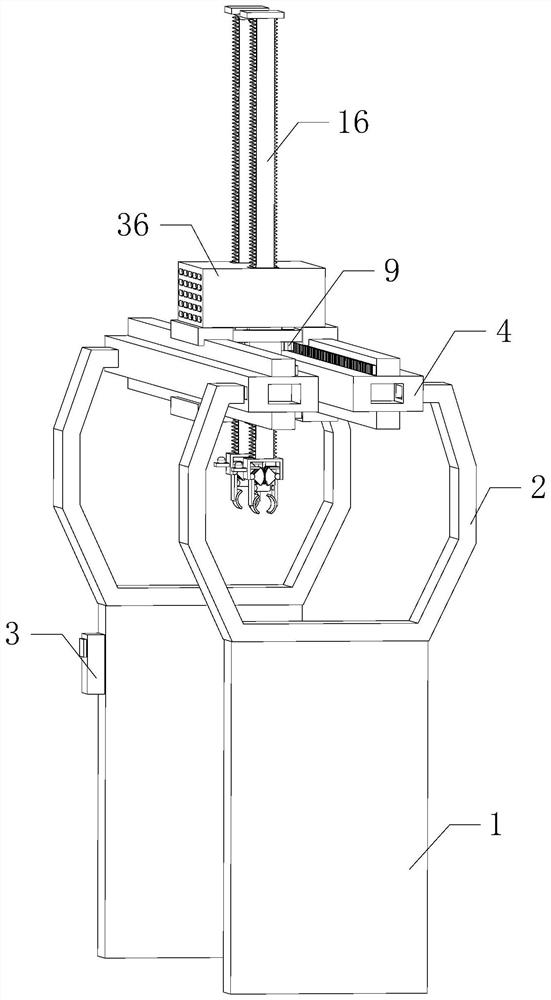

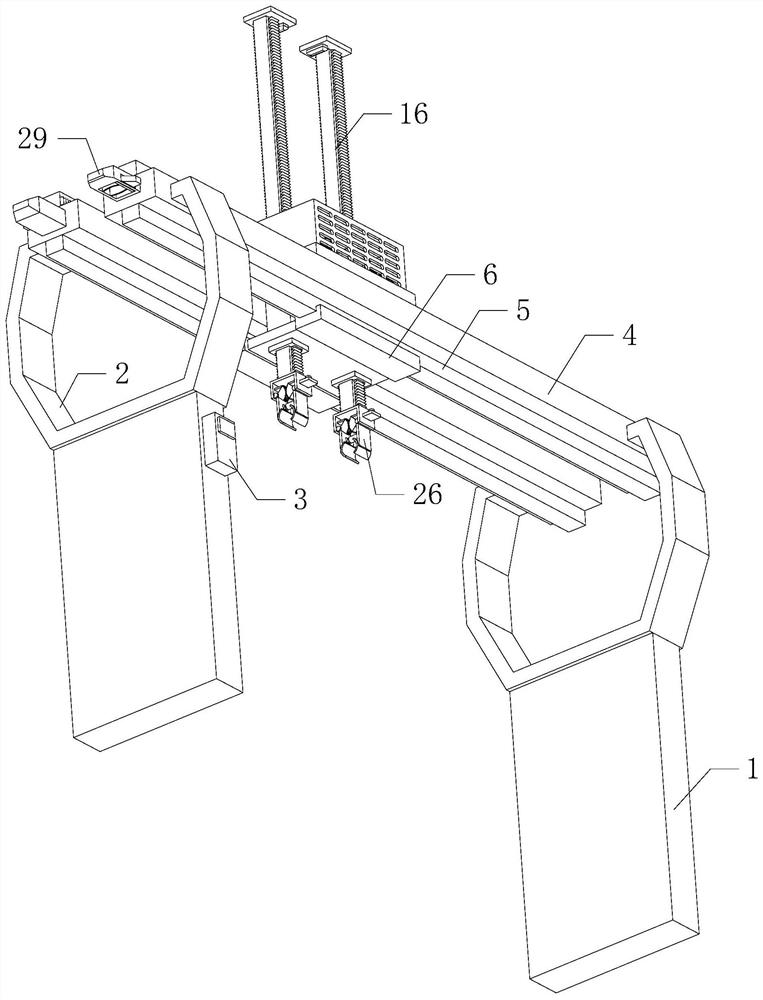

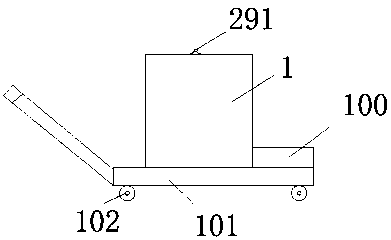

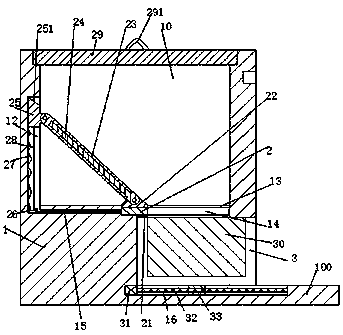

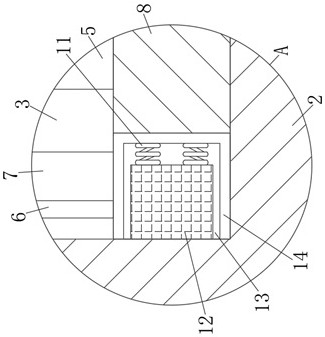

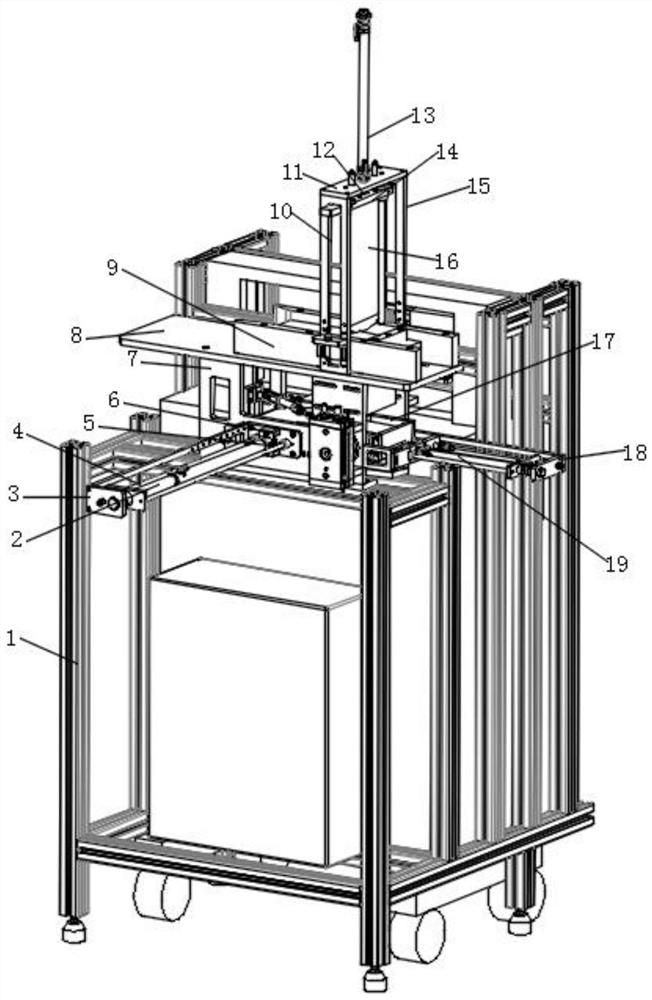

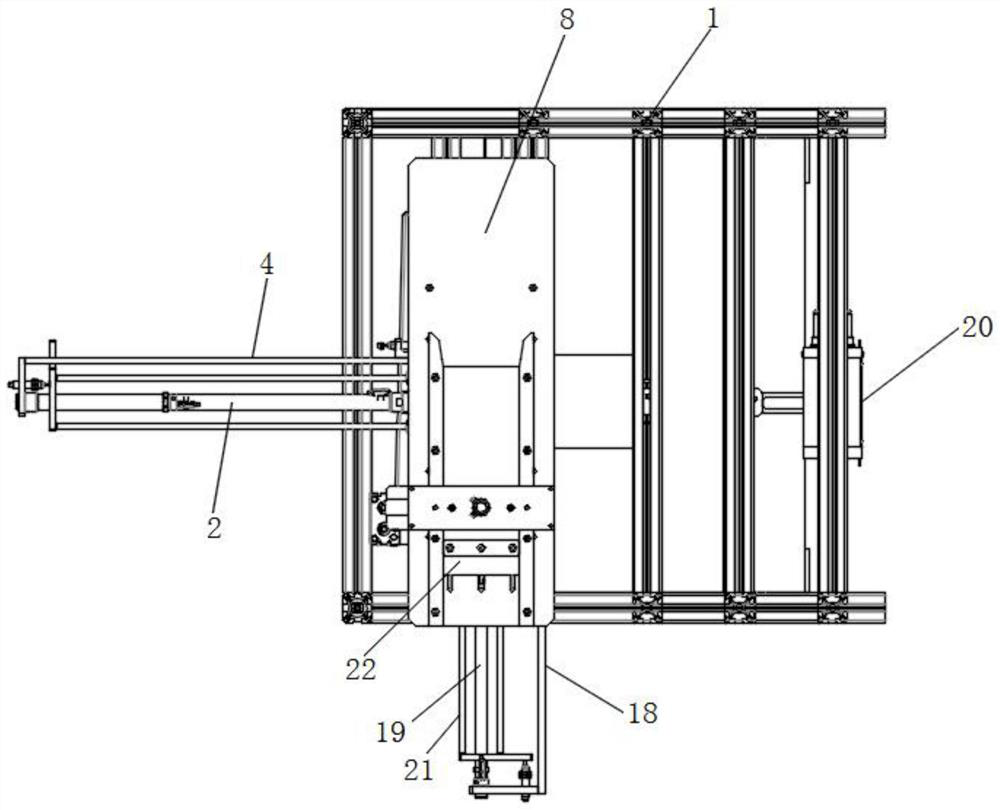

Automatic hoisting feeding and discharging device for mechanical equipment manufacturing workshop

InactiveCN112456316AEasy to dissipate heatImprove practicalityMetal working apparatusLoad-engaging elementsStructural engineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to an automatic hoisting feeding and discharging device for a mechanical equipment manufacturing workshop. Accordingto the automatic hoisting feeding and discharging device, automatic feeding and discharging work is conducted on mechanical equipment in the workshop, multiple sets of equipment in the workshop can conveniently work cooperatively, manpower and time for manual feeding and discharging and workpiece transferring are saved, the workpiece machining manner is simplified, and the work efficiency is improved; and meanwhile, the equipment in the running state is prevented from hurting workers, and practicability and safety are improved. The automatic hoisting feeding and discharging device comprises two sets of supporting legs, two sets of U-shaped frames, a center control box and two sets of long fixing plates. The bottoms of the two sets of U-shaped frames are arranged on the two sets of supporting legs correspondingly. The center control box is arranged on the front side of the supporting leg on the left side. The two sets of long fixing plates are located on the upper sides of the two setsof U-shaped frames. The left sides and the right sides of the outer side walls of the two sets of long fixing plates are arranged on the front sides and the rear sides of the tops of the two sets ofU-shaped frames correspondingly.

Owner:苏州立科工业设计有限公司

Improved type bridge equipment

InactiveCN108103910ASimple device structureEasy to fall intoRoads maintainenceEngineeringSlide plate

Owner:泉州旗信专利技术咨询有限公司

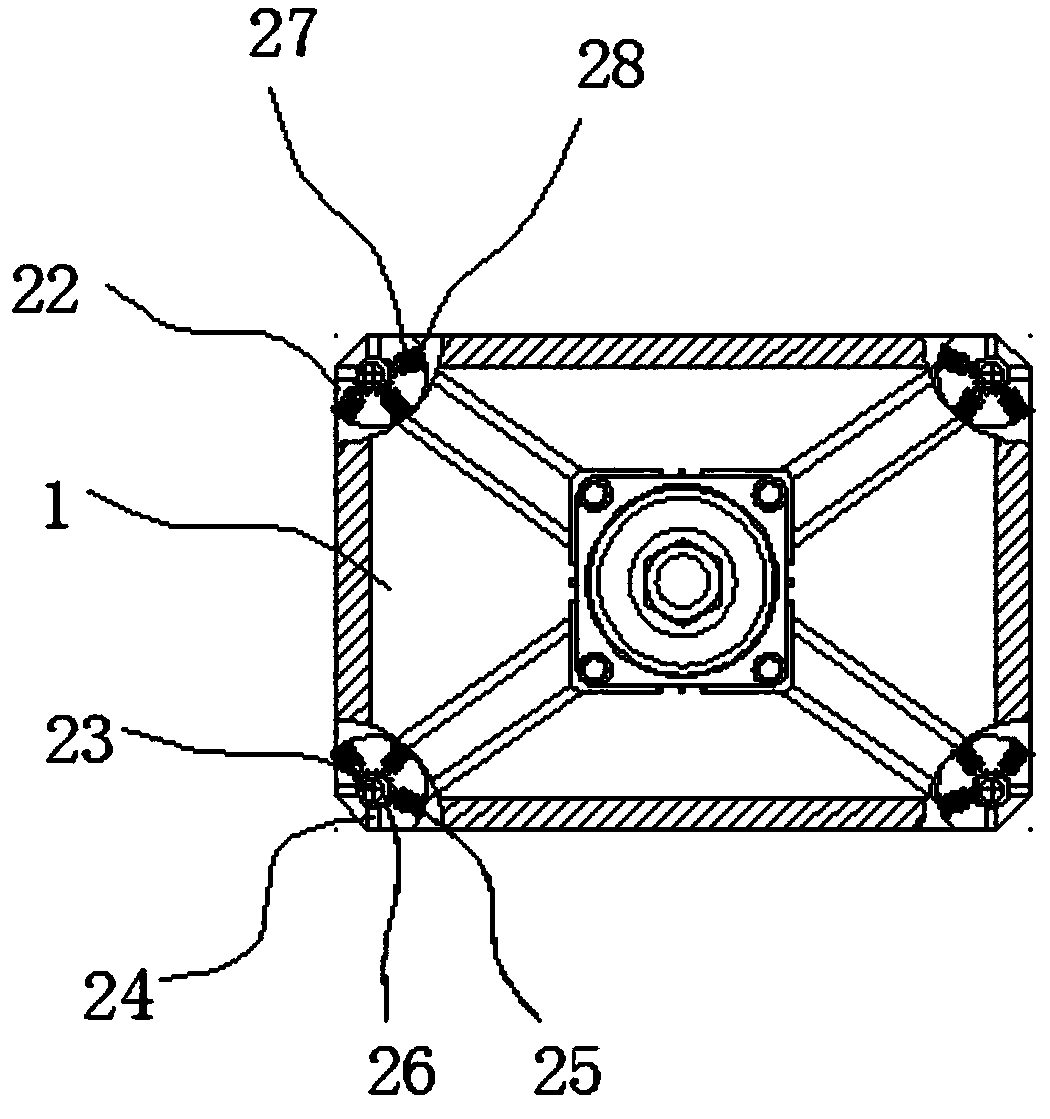

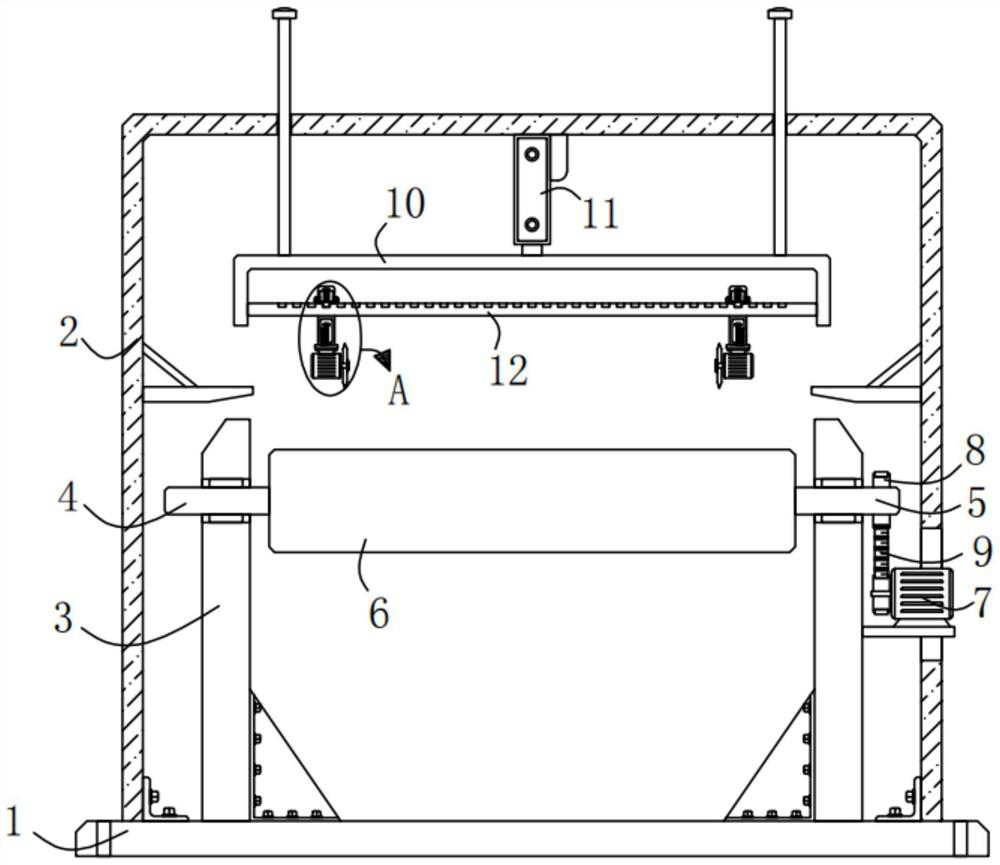

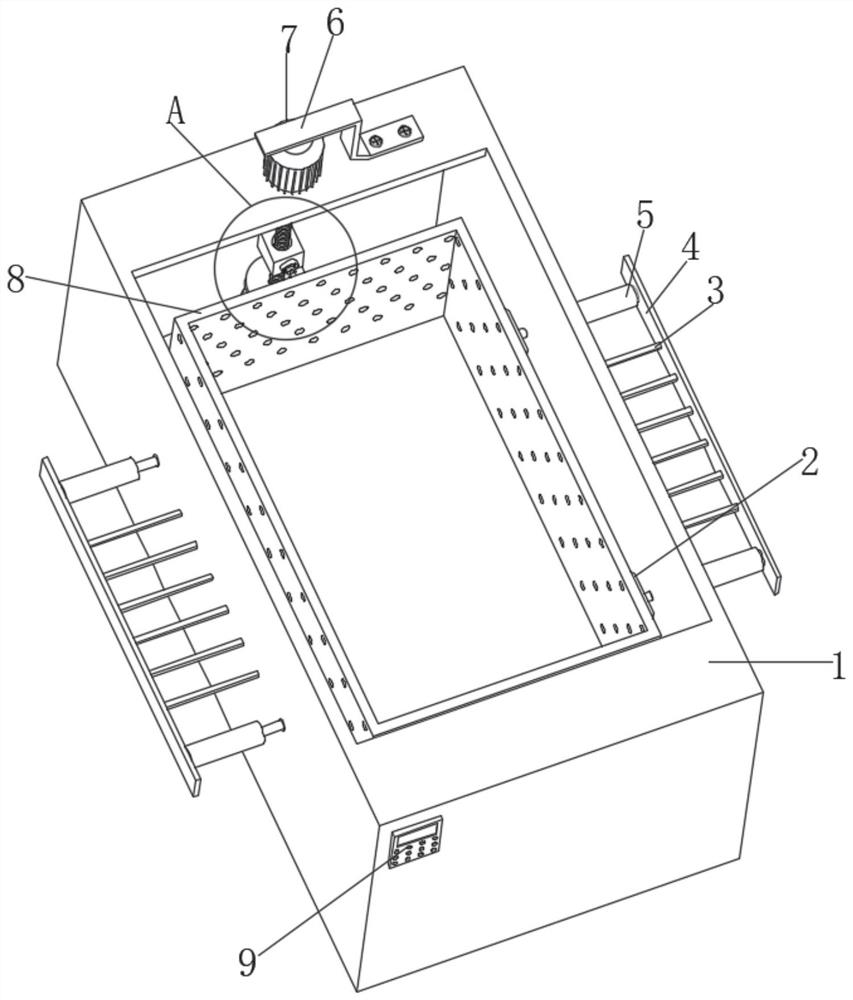

Arrangement device for electronic component packaging

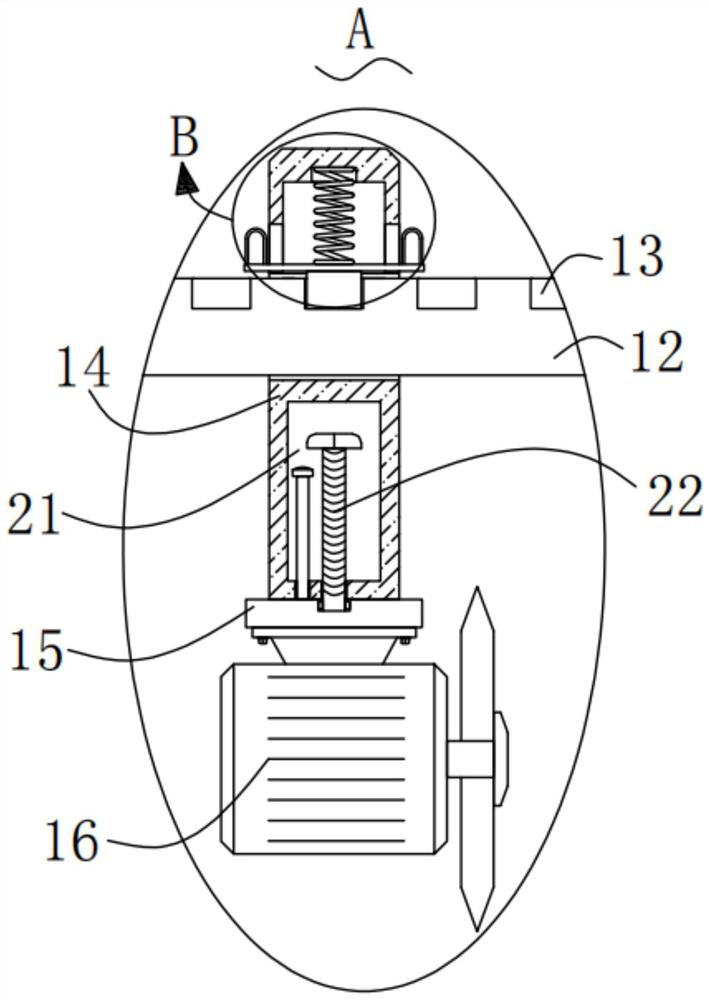

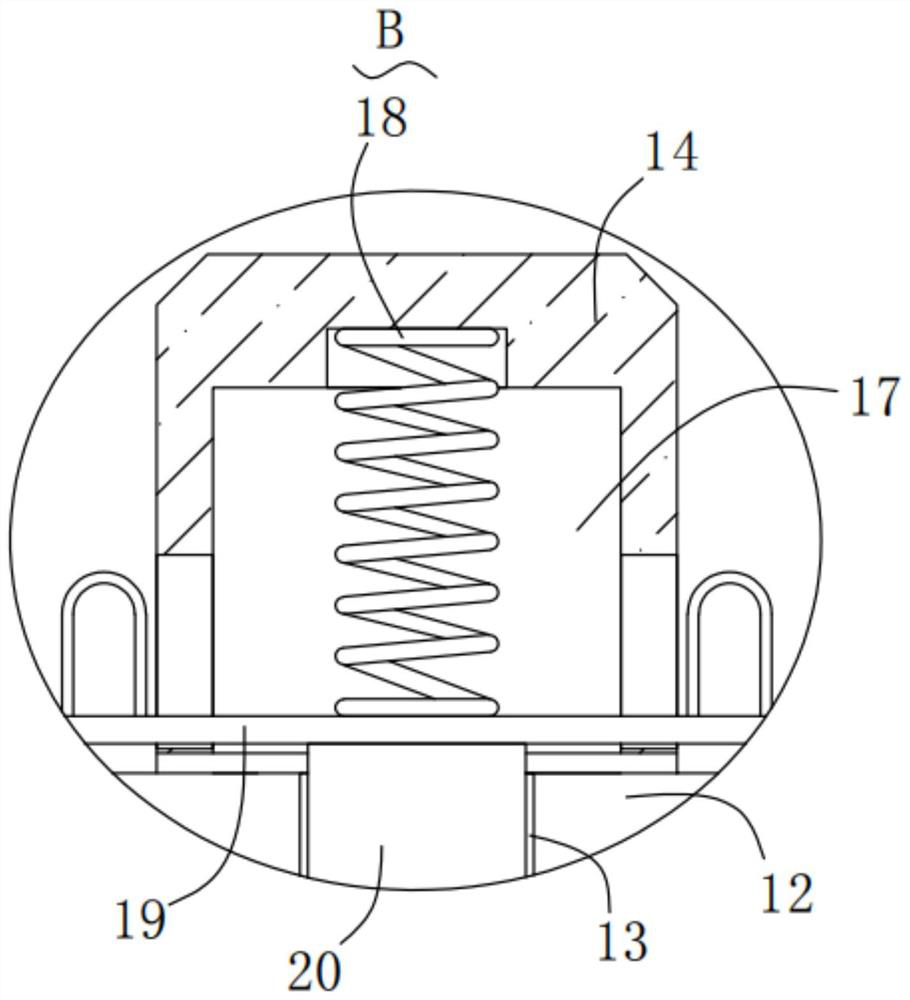

InactiveCN114684414AOrderly rowsConvenient pick-up workPackagingReciprocating motionElectric machinery

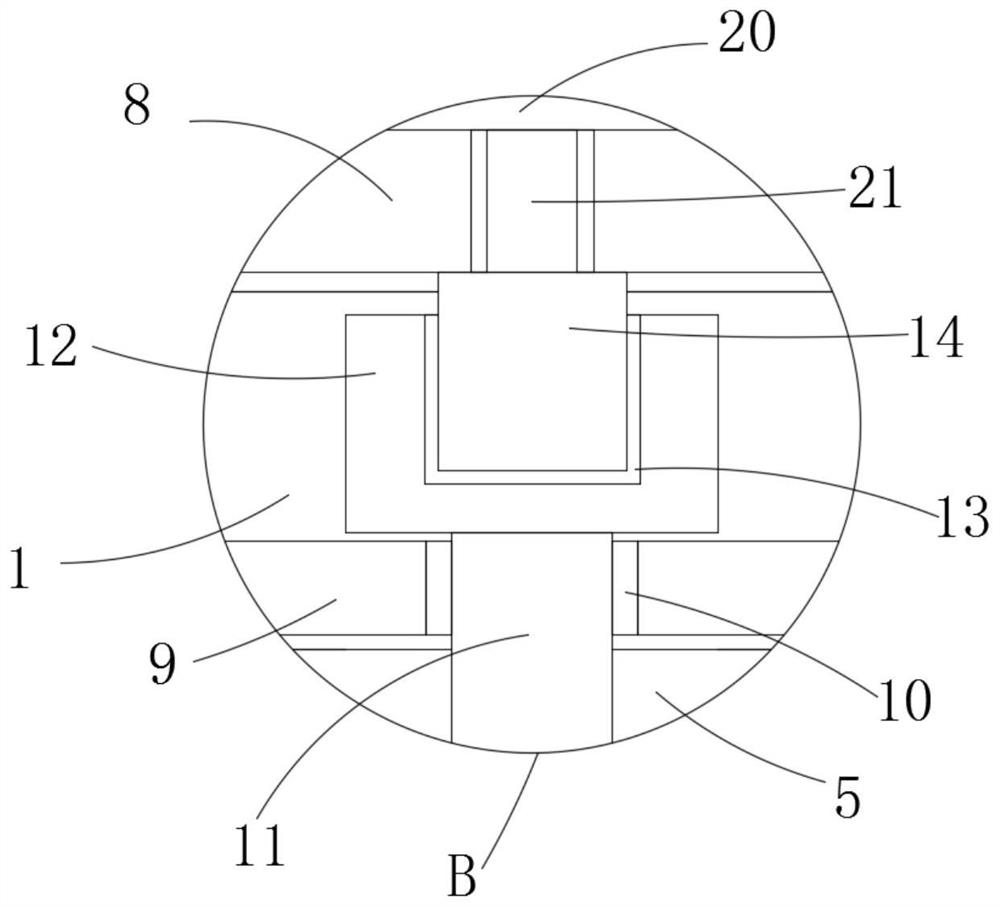

The invention relates to an arrangement device, in particular to an arrangement device for electronic component packaging. The invention aims to provide a time-saving and labor-saving arrangement device for electronic component packaging. The arrangement device for electronic component packaging comprises a base, a frame body, an arrangement plate, a clamping mechanism and the like, the frame body is arranged at the top of the base, and the arrangement plate used for conducting shaking arrangement on electronic components is arranged on the upper portion of the inner side of the frame body in a sliding mode. A clamping mechanism used for driving the material arranging plate to reciprocate left and right is arranged on the upper portion of the frame body. According to the electronic component sorting device, the motor serves as driving force, the cam can be driven to rotate, then the sorting plate can be driven to do left-right reciprocating motion under cooperation of the first spring, so that electronic components are shaken, the electronic components can be arranged in the strip-shaped grooves in the sorting plate in order, sorting work is completed, and time and labor are saved.

Owner:深圳市顺博兴电子有限公司

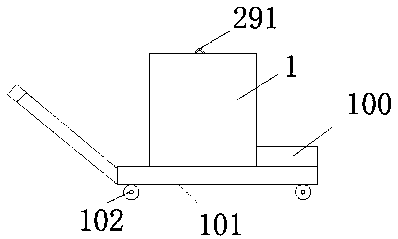

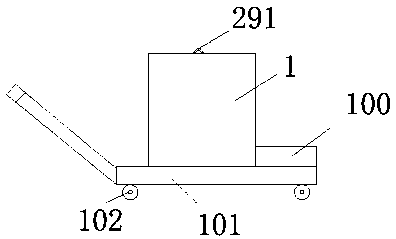

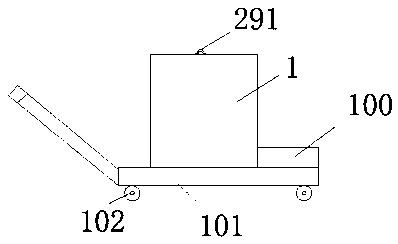

Raw material transportation device for lithium battery processing

InactiveCN112776859AAchieve liftingConvenient pick-up workSupporting partsHand carts with multiple axesStructural engineeringMechanical engineering

The invention discloses a raw material transportation device for lithium battery processing, wherein the raw material transportation device comprises a base; a pushing handle is arranged on the side wall of the base, locking universal wheels are arranged on the side wall of the bottom of the base, a groove is formed in the upper end of the base, a placing plate is arranged in the groove, and a placing groove is formed in the upper end of the placing plate; two connecting grooves are symmetrically formed in the inner bottom of the placing groove; a plurality of first springs are arranged at the inner bottoms of the two connecting grooves; the upper ends of the first springs are jointly and fixedly connected with a buffer plate; a containing basin is placed on the buffer plate; limiting grooves are formed in the opposite inner side walls of the placing groove; fixing plates are arranged at the two ends of the buffer plate, and the two fixing plates extend into the limiting grooves opposite to the fixing plates and are in sliding connection with the inner side walls of the fixing plates. The raw material transportation device is reasonable in structural design, a worker can conveniently conduct discharging work of the containing basin, and then the processing efficiency can be improved.

Owner:徐州金固新材料科技有限公司

Traction device capable of ensuring no burrs in electrostatic spinning

The invention provides a traction device capable of ensuring no burrs in electrostatic spinning. The traction device capable of ensuring no burrs in electrostatic spinning comprises a base; a frame I fixedly mounted at the top of the base; two supporting side plates both fixedly mounted at the top of the base; a connecting shaft I and a connecting shaft II rotationally mounted on the two supporting side plates respectively; a winding roller arranged between the two supporting side plates; a motor fixedly mounted on the supporting side plate far away from the connecting shaft I; and two synchronous belt wheels fixedly arranged on an output shaft of the motor and the connecting shaft II in a sleeving mode correspondingly. The traction device capable of ensuring no burrs in electrostatic spinning provided by the invention has the advantages that the burrs can be automatically cut off, people can conveniently collect fibers, a winding roller can be conveniently disassembled and assembled, and people can conveniently take materials.

Owner:MINJIANG UNIV

Folding and collecting device for thermal insulation cushion for building material processing and its use method

ActiveCN110371651BEasy to collectNeatly foldedFolding thin materialsPackagingHydraulic cylinderThermal insulation

Owner:马鞍山市金韩防水保温工程股份有限公司

A production mold for rubber products and a method for preparing rubber products

ActiveCN111844558BPrecise positioningNo need for manual positioningProcess engineeringMechanical engineering

The invention discloses a mold for producing rubber products, which comprises a bottom box and a protective box. A fixed mold is arranged in the middle of the top surface of the bottom box, and clamping plates are respectively arranged at the four corners of the fixed mold. Each clamping plate One end is provided with a rotating shaft, and one end of the rotating shaft is arranged on the top surface of the bottom box, and the positions of several feeding holes correspond to the positions of the discharge heads on the mounting seat, so that several discharge heads are inserted into the inside of several feed holes, A number of cavities with different shapes of the mold are fed, realizing simultaneous processing of multiple molds and improving mold processing efficiency; the first piston rod drives the second moving plate to move upwards, so that the movable mold is separated from the fixed mold, which is convenient for material removal. , to solve the phenomenon that the mold is hard to separate from the movable mold and the fixed mold after it is glued together. The bolt fixing method is convenient for disassembly and replacement of the fixed mold.

Owner:NINGGUO RUIPUSLS

Efficient bridge equipment

ActiveCN108103958AEasy to fall intoAvoid strandedBridge structural detailsBridge erection/assemblyEngineeringSlide plate

The invention relates to efficient bridge equipment. The bridge equipment includes a containing tank, a handcart is fixedly arranged at the bottom of the containing tank, and rolling wheels are simultaneously arranged at four corners of the bottom of the handcart. The containing tank is provided with a containing chamber with an opening facing upwards and a sliding groove with an opening facing rightwards, a cover body is mounted at the upper end of the containing chamber, a discharging opening is formed between the containing chamber and the sliding groove, a sliding piece is slidingly installed in the sliding groove, and a containing groove with an opening facing upwards is formed in the sliding piece. A straight plate extending rightwards is disposed at the right end of the bottom wallof the sliding groove, a first sliding groove with an opening facing upwards is formed in the bottom wall of the sliding groove and the straight plate, a first sliding block is slidingly installed inthe first sliding groove, and a threaded rod is cooperatively installed in the first sliding block through threads. The right end of the threaded rod is rotatably installed in the right end wall of the first sliding groove, the left end of the threaded rod is connected with a motor fixedly installed in the left end wall of the first sliding groove, a guide moving groove extending horizontally is formed in the front and rear end walls of the discharging opening, and a sliding plate extending in the front and back directions is slidingly installed in the guide moving groove.

Owner:泉州旗信专利技术咨询有限公司

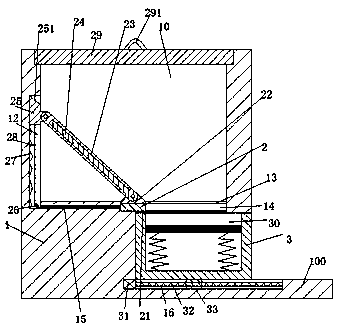

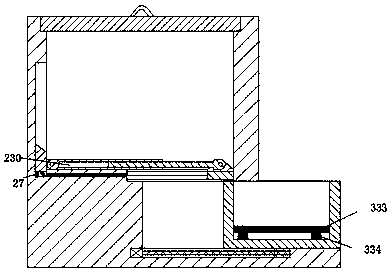

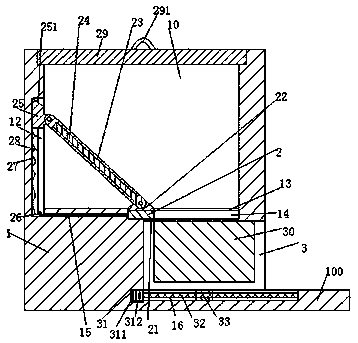

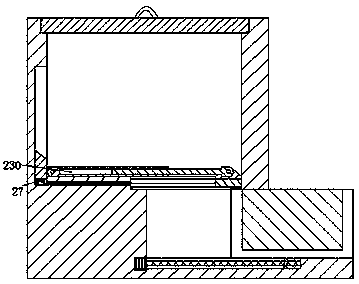

Scalding device for primary processing of agricultural products

InactiveCN113693125AConvenient loading workConvenient pick-up workSeed preservation by heatingAgricultural scienceAgricultural engineering

The invention relates to a scalding device, and particularly relates to a scalding device for primary processing of agricultural products. The scalding device comprises a box body and a scalding box arranged in the box body, wherein the outer wall of the top of the box body is fixedly connected with a driving assembly for driving the scalding box to move vertically; the outer wall of one side of the driving assembly is fixedly connected with an elastic assembly for guaranteeing stability of the scalding box; a heating pipe is arranged in the box body; and the outer walls of two sides of the box body are fixedly connected with a temperature sensor and a control panel respectively. According to the scalding device, a worker can perform feeding work before scalding of the agricultural products and take materials after scalding of the agricultural products conveniently by the aid of a lifting assembly, the scalding box can be driven to move vertically during scalding work of the agricultural products, so that the agricultural products in the scalding box can be contacted with hot water uniformly and sufficiently, the scalding efficiency of the agricultural products is improved, and the scalding uniformity of the agricultural products is guaranteed.

Owner:新晃侗族自治县易同云网科技有限公司

A splicing device for polarizer production equipment

ActiveCN113387166BConvenient pick-up workImprove stabilityConveyor partsMechanical conveyorsHydraulic cylinderEngineering

The invention discloses a material splicing device of a polarizer production equipment, comprising a worktable, a support table is installed and fixed on the worktable, a turntable is rotatably installed on the support table, and a material receiving table is also arranged on the support table The material receiving assembly includes a support table and a material receiving box, two transport guide rails for transporting the material receiving box are also provided on the worktable, and the material receiving box is also provided with a transport guide rail for use Four sets of support rods are also installed and fixed on the worktable, and first electric guide rails are installed on the two sets of support rods parallel to the transport guide rails, which are slidably installed on the first electric guide rails. There is a fixing plate, several groups of hydraulic cylinders are arranged on the fixing plate, and a feeding plate is installed and fixed on the ejecting end of the hydraulic cylinder. The invention has novel structure and functions, and can effectively improve the production efficiency of polarizers.

Owner:深圳市运宝莱光电科技有限公司

Material receiving device of polaroid production equipment

ActiveCN113387166AConvenient pick-up workImprove stabilityConveyor partsMechanical conveyorsHydraulic cylinderEngineering

The invention discloses a material receiving device of polaroid production equipment. The device comprises a workbench. A supporting table is installed and fixed on the workbench, a rotary table is rotationally installed on the supporting table, and a material receiving assembly is further arranged on the supporting table and comprises a supporting platform and a material receiving box. Two conveying guide rails used for conveying the material receiving box are further arranged on the workbench, and sliding grooves which are used in cooperation with the conveying guide rails are further formed in the material receiving box. Four supporting rods are further installed and fixed on the workbench, and first electric guide rails are further installed on the two supporting rods which are parallel to the conveying guide rails. A fixing plate is installed on the first electric guide rails in a sliding mode, a plurality of hydraulic cylinders are arranged on the fixing plate, a material receiving plate is installed and fixed at the ejection ends of the hydraulic cylinders, and a suction disc assembly used for absorbing and carrying polaroids is arranged on the material receiving plate. The device is novel in structure and practical in function, and the production efficiency of the polaroids is effectively improved.

Owner:深圳市运宝莱光电科技有限公司

A vacuum stirrer for battery production

ActiveCN109012421AConvenient pick-up workShaking/oscillating/vibrating mixersTransportation and packagingEngineeringDriven element

A vacuum stirrer for battery production is disclosed. The vacuum stirrer includes a stirring tank, an equipment tank disposed on the stirring tank, a conveying pipe communicating with the stirring tank and a material storage tank disposed at one side of the stirring tank. One end of the conveying pipe is above the material storage tank. One side of the stirring tank is provided with a feeding port. The bottom of the stirring tank is provided with heating blocks. A stirring motor is disposed in the equipment tank, and an output shaft of the stirring motor is in transmission connection with a stirring shaft penetrating and disposed in the stirring tank. One end of the conveying pipe is disposed in the stirring tank. The stirring tank is provided with a sealing device. A mounting table is disposed at one side of the stirring tank and is provided with a drive element used for driving the conveying pipe to move up and down. The conveying pipe is provided with a material suction assembly. Through cooperation of the material suction assembly of the conveying pipe and the drive element, the conveying pipe plays a role of vacuumization before material stirring and plays a role of material suction after material stirring is finished.

Owner:邳州市景鹏创业投资有限公司

Novel bridge equipment

Owner:唐山荣久科技有限公司

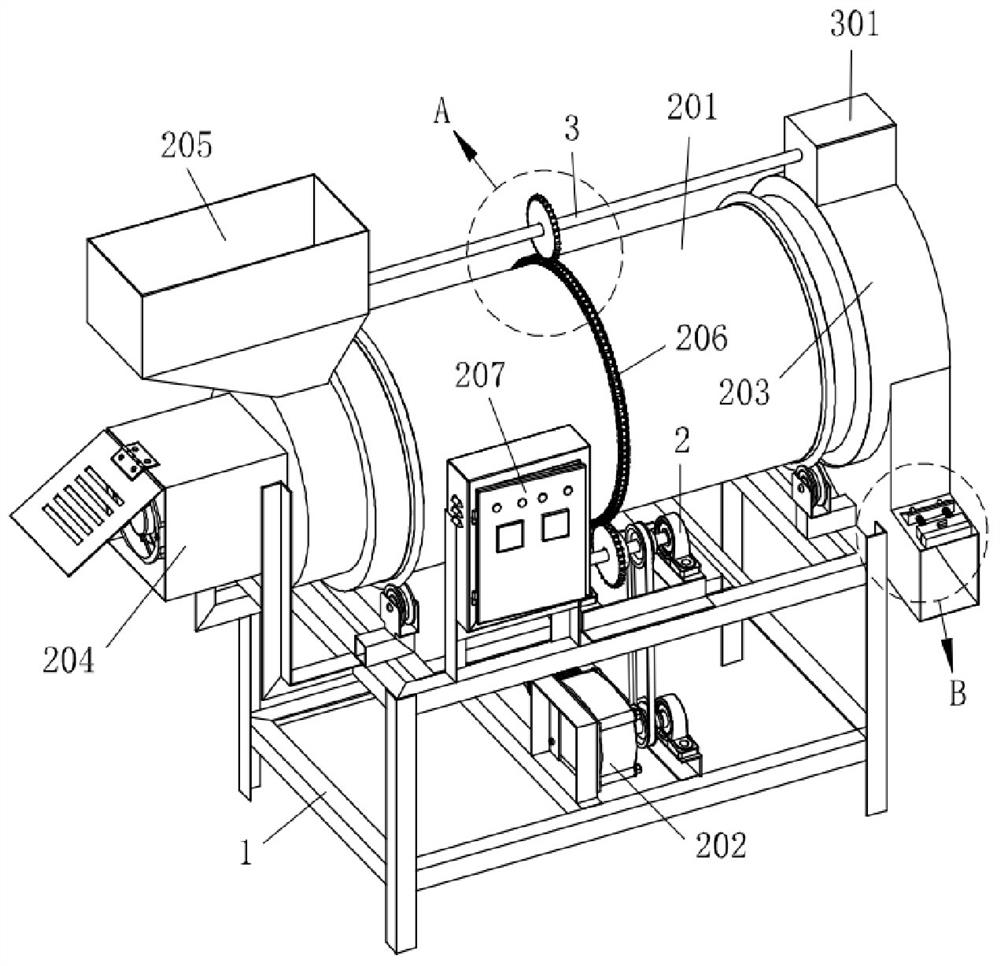

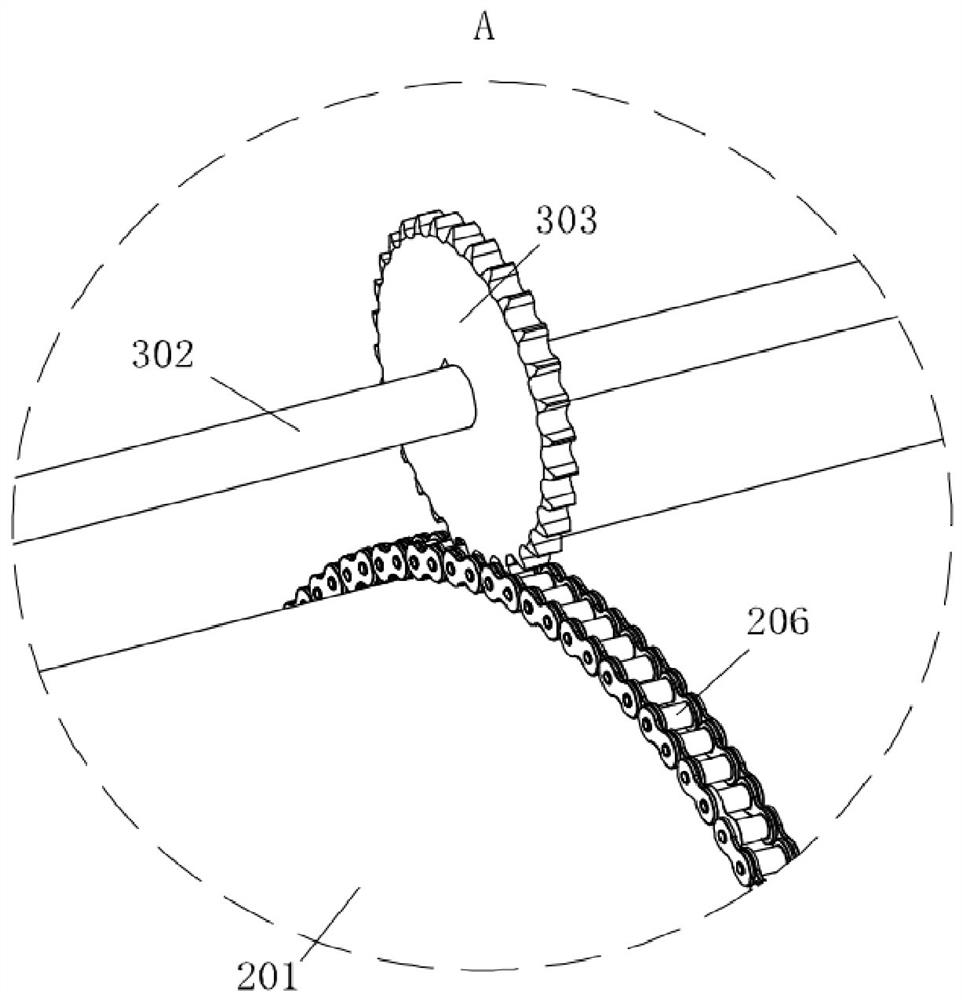

White carbon black processing and drying device

InactiveCN114777444AGood for pre-shreddingGood for tumble dryingDrying gas arrangementsDrying chambers/containersProcess engineeringCaking

The invention relates to the technical field of drying, in particular to a white carbon black processing and drying device which comprises a rack, a drying mechanism is mounted on the rack, a crushing mechanism is mounted on the drying mechanism, a shaking mechanism is mounted on the drying mechanism, a lubricating mechanism is mounted on the drying mechanism, and a screening mechanism is connected to the drying mechanism. A clamping mechanism is mounted on the drying mechanism; the white carbon black can be conveniently overturned and dried through the drying mechanism, the white carbon black is pulverized in advance under the action of the crushing mechanism, the phenomenon that the caked white carbon black cannot be rapidly dried is prevented, the shaking mechanism and the lubricating mechanism work under the driving of the crushing mechanism, the white carbon black is smoothly fed, the crushing mechanism is lubricated, and the drying efficiency is improved. The screening mechanism works through the crushing mechanism, impurities can be filtered and screened out of dried white carbon black, a packaging bag for material receiving is convenient to disassemble and assemble through installation of the clamping mechanism, and operation is more convenient.

Owner:徐州中兴化工有限公司

A combination rolling machine

The invention discloses a combined veneer reeling machine. The combined veneer reeling machine comprises a rack, an upper roller and a lower roller, wherein a guide rail parallel to the upper roller is arranged on the rack, and a working screw rod connected with a driving motor is arranged in the guide rail; the two ends of the working screw rod are both in threaded connection with a sliding block, the two sliding blocks can move face to face or oppositely, and a supporting frame is fixedly arranged on each sliding block; each supporting frame is provided with a cooling device. Each cooling device comprises a sponge mat arranged on the corresponding supporting frame, wherein the top of the sponge mat is fixedly connected with the supporting frame, a connecting piece is fixedly arranged atthe bottom of the sponge mat, and a connecting ring is arranged on the connecting piece. A plurality of positioning hooks for the connecting rings to sleeve are arranged on the sliding blocks, the positioning hooks are sequentially arrayed on the sliding blocks from low to high, and a water outlet mechanism which is communicated with the sponge mats is arranged on the rack. The combined veneer reeling machine is additionally provided with the cooling devices for reeled veneers so that working personnel can conveniently take materials and work, work accidents can be reduced and the working efficiency can be improved.

Owner:JIANGSU MINGYU NEW ENERGY RESOURCES

a bridge device

Owner:唐山荣久科技有限公司

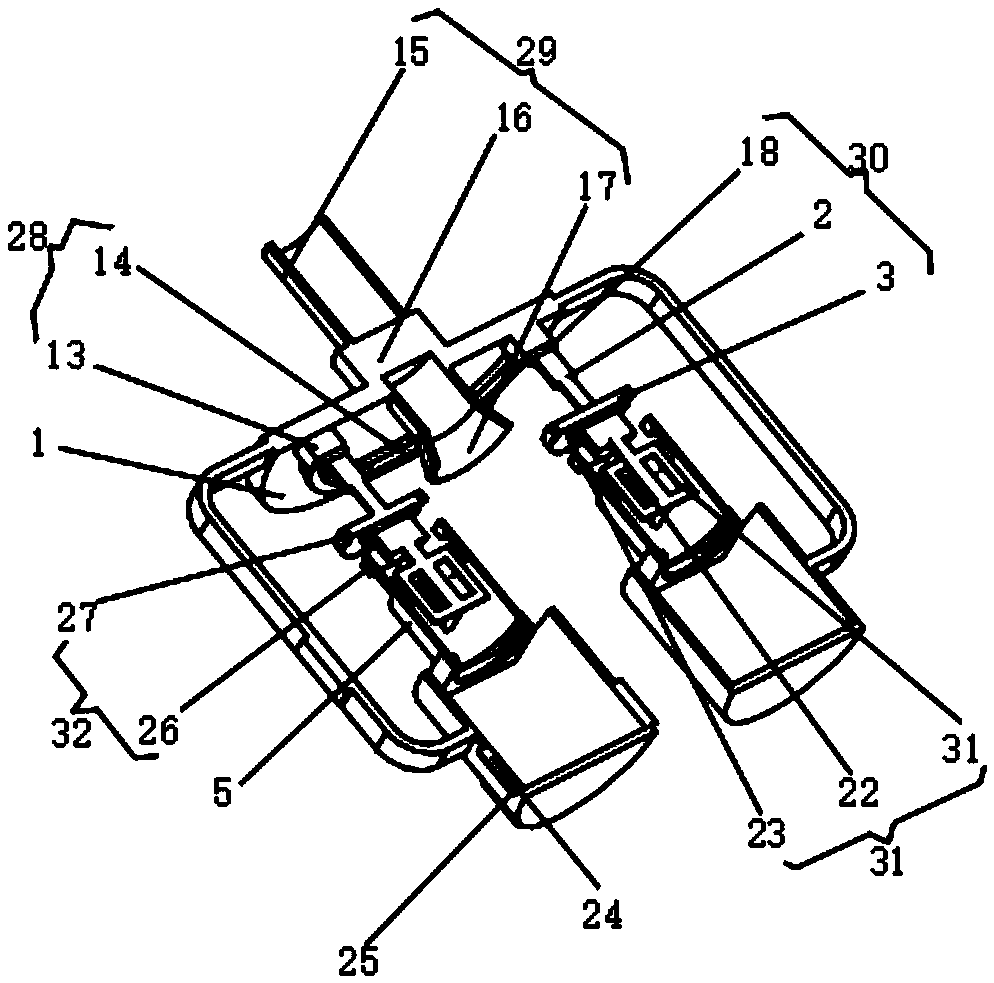

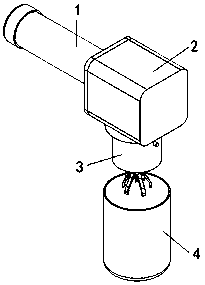

Telescopic rope device capable of picking up articles falling into crack

PendingCN111390894AConvenient pick-up workEasy to collectProgramme-controlled manipulatorGripping headsElectric machineryStructural engineering

The invention discloses a telescopic rope device capable of picking up articles falling into a crack, in particular to a viscous telescopic rope device capable of picking up articles falling into thecrack. The telescopic rope device comprises a hand-held pipe, one end of the hand-held pipe is connected with a rope storage box, the lower end of the rope storage box is connected with an article picking assembly, the article picking assembly includes a driving mechanism, and the lower end of the driving mechanism is connected with a clamping and sticking mechanism. According to the telescopic rope device, through the common cooperation of a first mini motor, a winding roller, the driving mechanism and the clamping and sticking mechanism, small articles such as earrings and necklaces can be clamped up, and large objects such as mobile phones can be taken out by sticking. In addition, the extension length of a telescopic rope can be adjusted according to the depth of the crack, so that theobject picking work is greatly facilitated. The telescopic rope device is simple in structure and convenient to store, carry and use.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com