Polishing equipment for edge opening of high-frequency plate after drilling

A high-frequency board and equipment technology, which is applied in the field of high-frequency board drilling and edge grinding equipment, can solve the problems of high-frequency board damage, time-consuming, laborious, and omission, and achieve the effects of reducing operations, good results, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

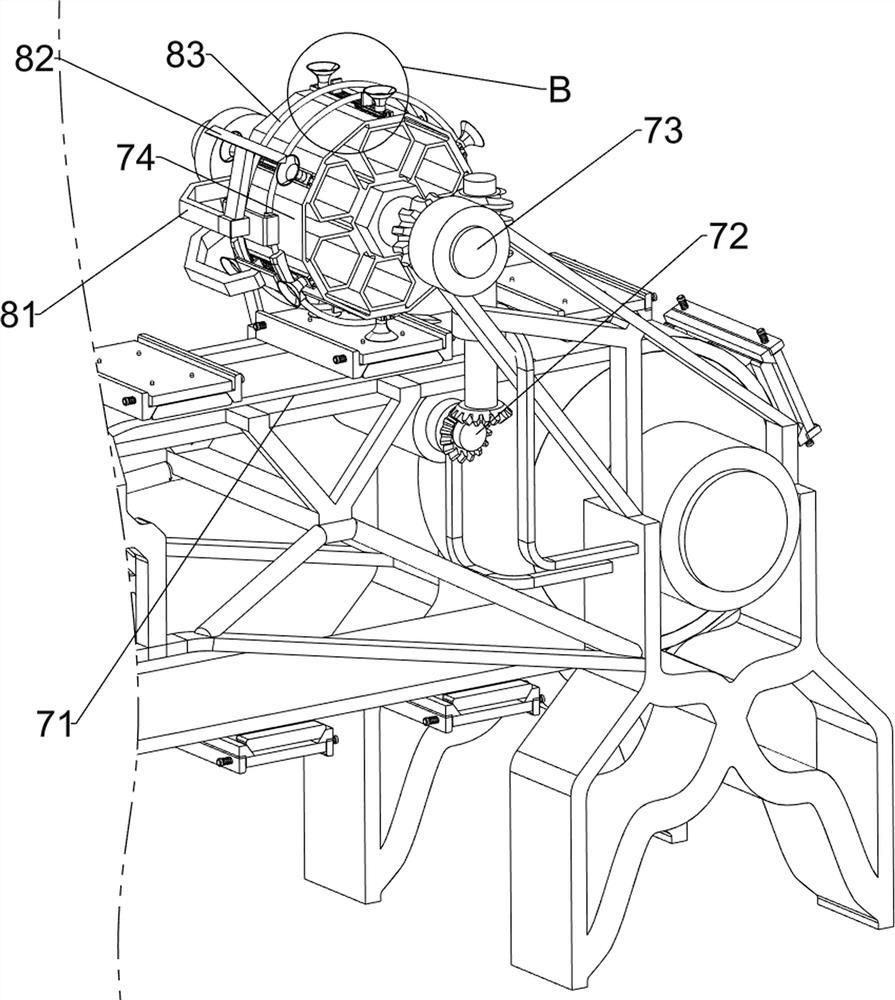

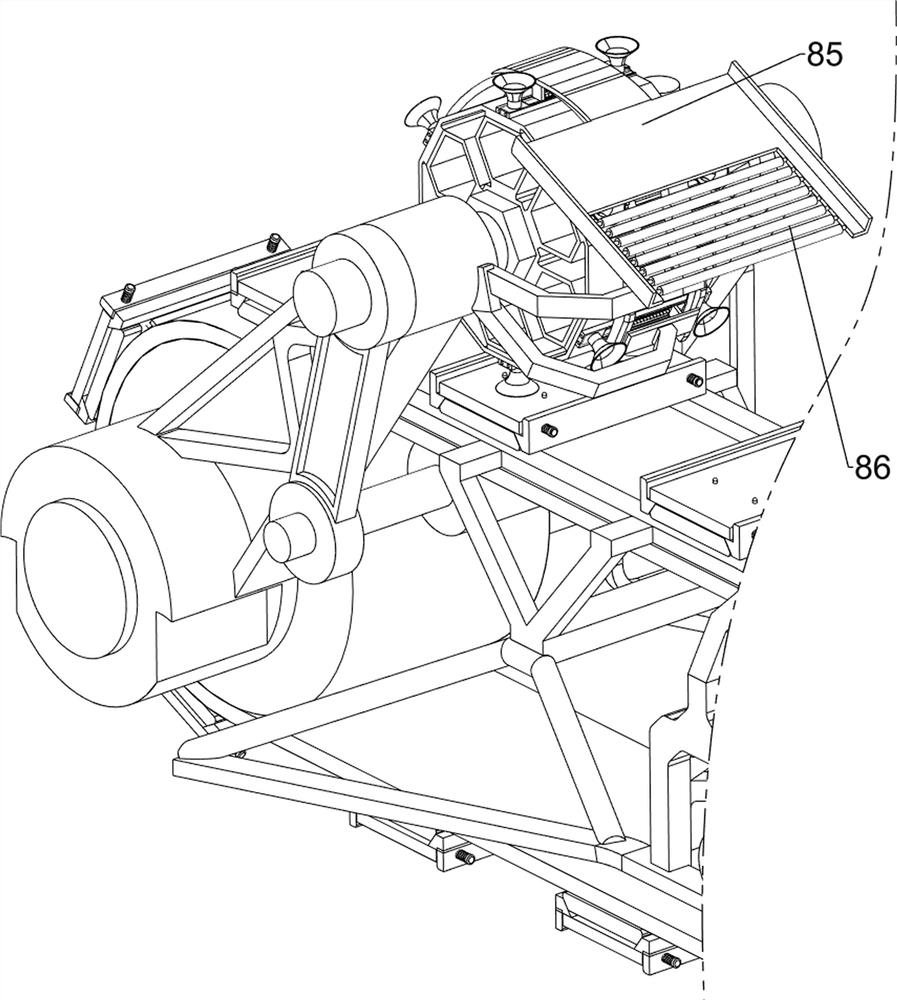

[0027] A kind of high-frequency plate drilling back edge grinding equipment, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a motor 2, a feeding mechanism 3, a clamping mechanism 4 and a grinding mechanism 5, a motor 2 is provided in the middle of the base 1, a feeding mechanism 3 is provided on the front and rear sides of the upper part of the base 1, and a feeding mechanism 3 is provided on the feeding mechanism 3. The clamping mechanism 4 is provided with a grinding mechanism 5 on the middle side of the upper part of the base 1 .

[0028] The feeding mechanism 3 includes a first transmission assembly 31, a first rotating shaft 32, a driving wheel 33, a conveyor belt 34, and a first wedge-shaped rod 35. The front and rear sides of the middle part of the base 1 are rotatably provided with a first rotating shaft 32, and the front first rotating shaft 32 The left side is connected with the output shaft of the motor 2 with a first transmission assemb...

Embodiment 2

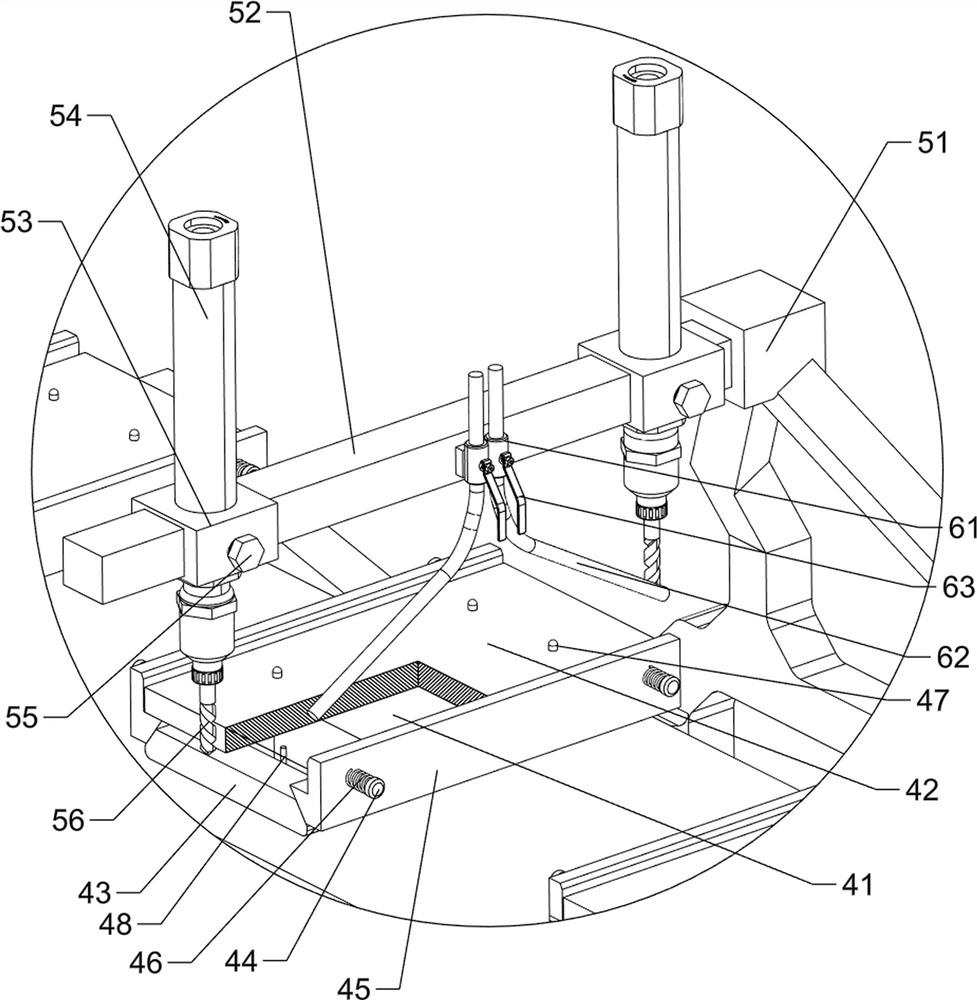

[0033] On the basis of Example 1, such as image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a dust removal mechanism 6 is also included. The dust removal mechanism 6 includes a valve 61, an air duct 62 and an adjustment handle 63. Two valves 61 are arranged in the middle of the second guide rod 52, and an air duct 62 is provided on the lower side of the valve 61. , The middle part of the valve 61 is provided with an adjustment handle 63 which is rotatable.

[0034] When the grinding work is carried out, people open the valve 61, and the direction of the air duct 62 can be controlled by manually rotating the adjustment handle 63, and the air duct 62 will blow out the waste scraps from the grinding, so that the grinding effect is better.

[0035] Also includes a material retrieving mechanism 7, the retrieving mechanism 7 includes a second wedge-shaped rod 71, a second transmission assembly 72, a second rotating shaft 73, a runner 74, a first block 75, a third guide rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com