Material receiving device of polaroid production equipment

A technology for production equipment and material receiving devices, which is used in transportation and packaging, mechanical conveyors, conveyor objects, etc., and can solve the problems of low degree of automation and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

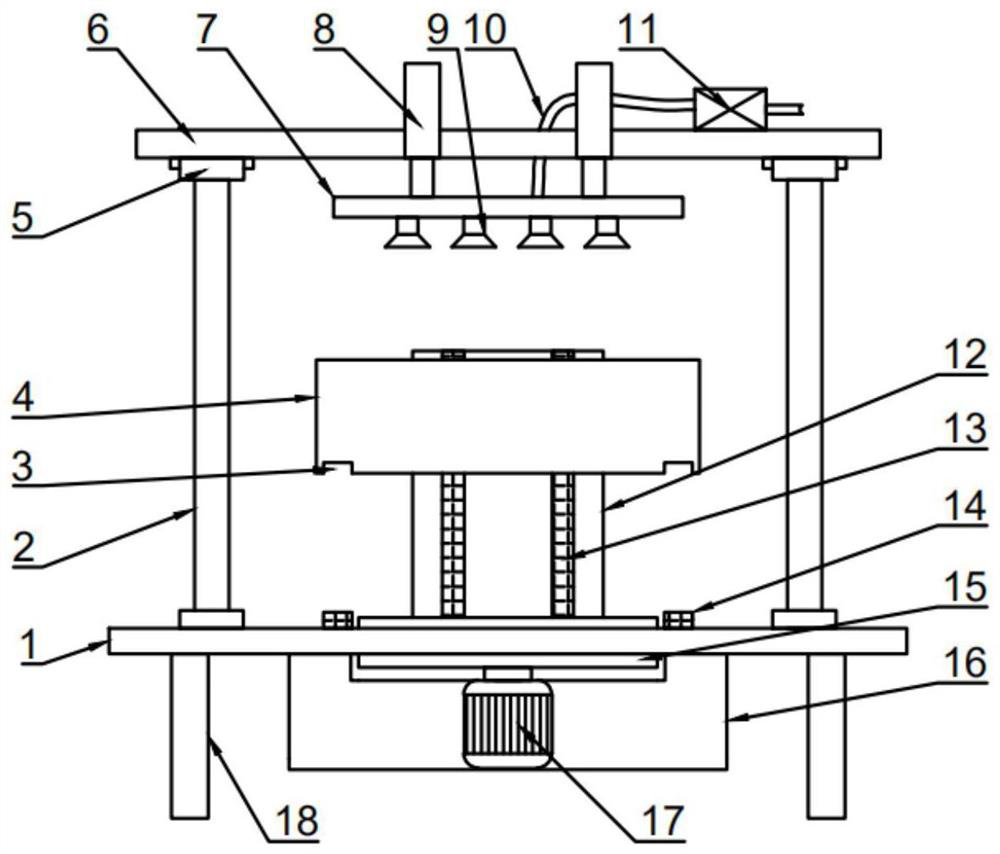

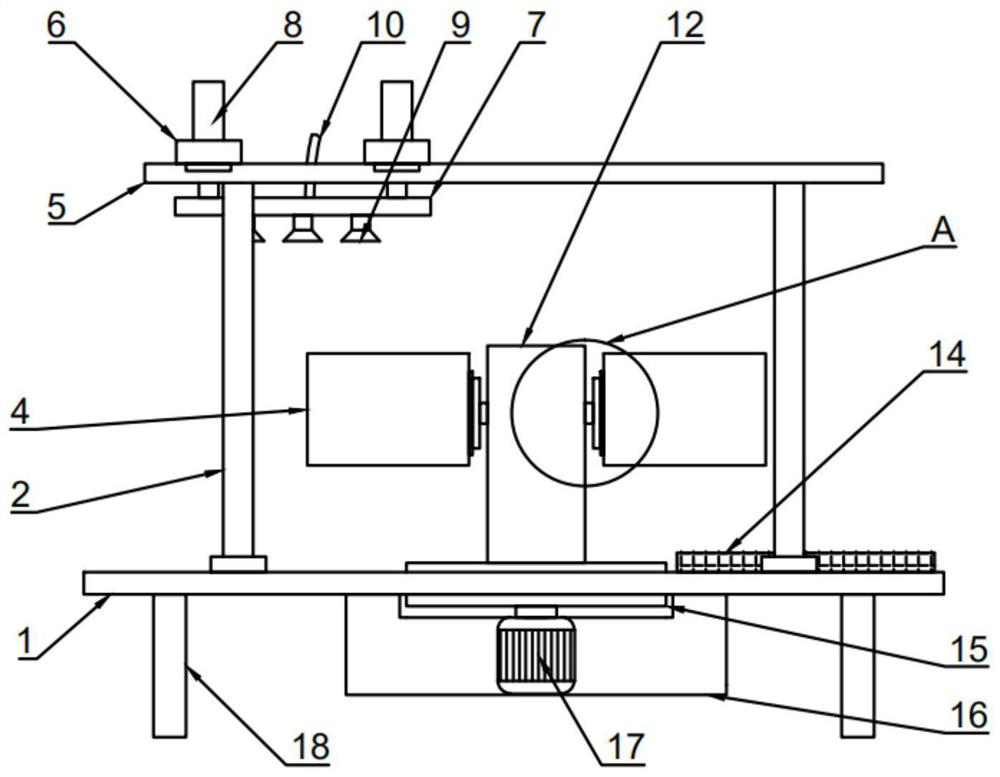

[0025] see figure 1 , 2 And 4, in the embodiment of the present invention, a material receiving device of polarizer production equipment includes a workbench 1, a support platform 16 is mounted and fixed on the workbench 1, and a turntable 15 is rotatably installed on the support platform 16, And the stepper motor 17 that is used to drive the rotation of the turntable 15 is also arranged in the supporting platform 16, the described supporting platform 16 is arranged through the workbench 1, and the described supporting platform 16 is also provided with a material receiving assembly, and the described material receiving assembly includes The support platform 12 and the receiving box 4, the support platform 12 is installed and fixed on the turntable 15, and two groups of second electric guide rails 13 are also symmetrically arranged on both sides of the support platform 12, and the material receiving box 4 passes through the magnetic attraction assembly Slidingly installed on t...

Embodiment 2

[0028] see Figure 1-6 , the difference between this embodiment and embodiment 1 is:

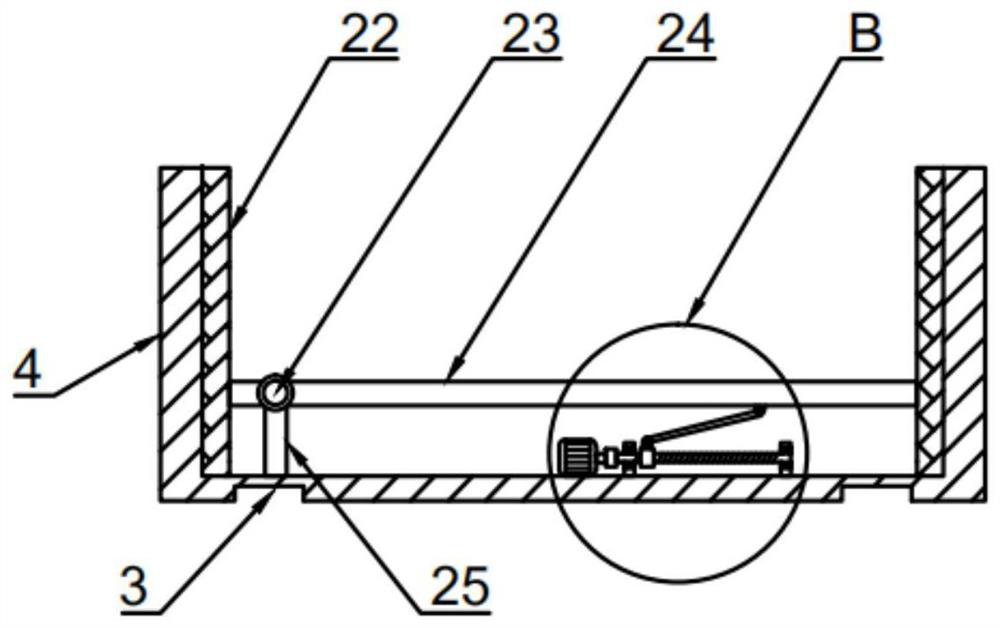

[0029]In this embodiment, the receiving box 4 is also provided with a support plate assembly for conveniently taking out the polarizer. The support plate assembly includes a support block 25 and a carrying plate 24, and the support block 25 is installed and fixed on the receiving plate. In the material box 4, one end of the loading plate 24 is installed on the support block 25 through the connecting shaft 23, and a screw assembly for driving the loading plate 24 to rotate on the support block 25 is also provided in the material receiving box 4. One end of the carrying plate 24 is rotated on the support block 25 with the connecting shaft 23 as the axis to make the other end of the carrying plate 24 tilt up. At this time, one end of the polarizer loaded in the receiving box 4 can be lifted from the receiving box 4 out, which is convenient for the staff to carry and use.

[0030] Described sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com