Seedling raising tray seeding equipment for agricultural seedling raising

A seedling tray and agricultural technology, which is applied in the field of seedling tray planting equipment for agricultural seedling raising, can solve the problems of wasting labor, low work efficiency, cumbersome operation process, etc., and achieve the effects of saving labor, improving work efficiency, and conveniently picking materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

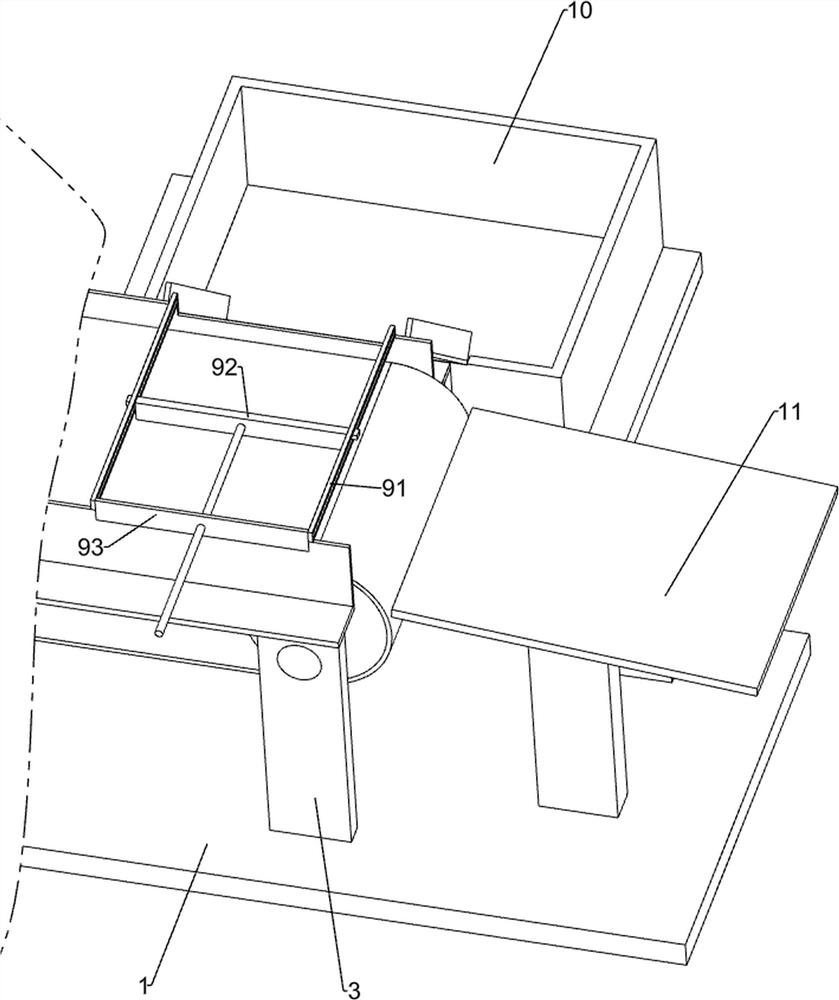

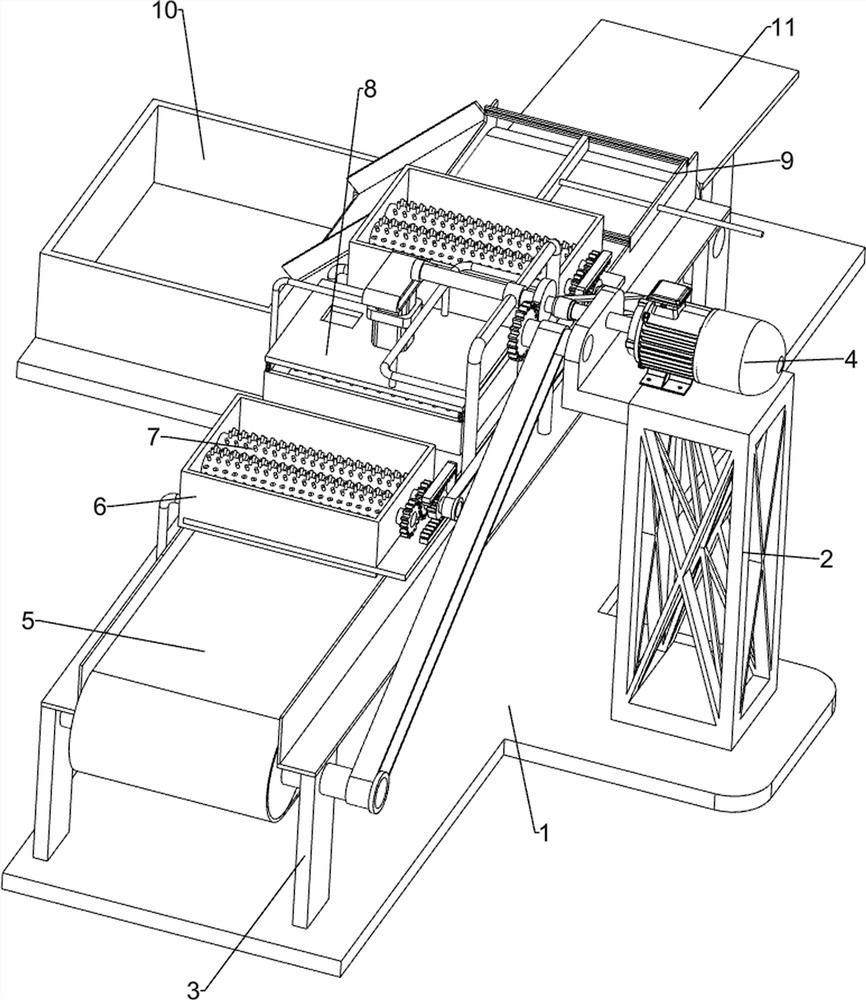

[0028] A seedling tray planting equipment for agricultural seedlings, such as Figure 1 to Figure 3 As shown, it includes a bottom plate 1, a placement frame 2, a support plate 3, a servo motor 4, a conveying mechanism 5, and a feeding mechanism 6. The top right side of the bottom plate 1 is connected to the placement frame 2, and the middle of the top of the bottom plate 1 is connected to a support plate 3. A servo motor 4 is connected to the placement frame 2 , a conveying mechanism 5 is connected between the placement frame 2 and the support plate 3 , and a feeding mechanism 6 is connected to the support plate 3 .

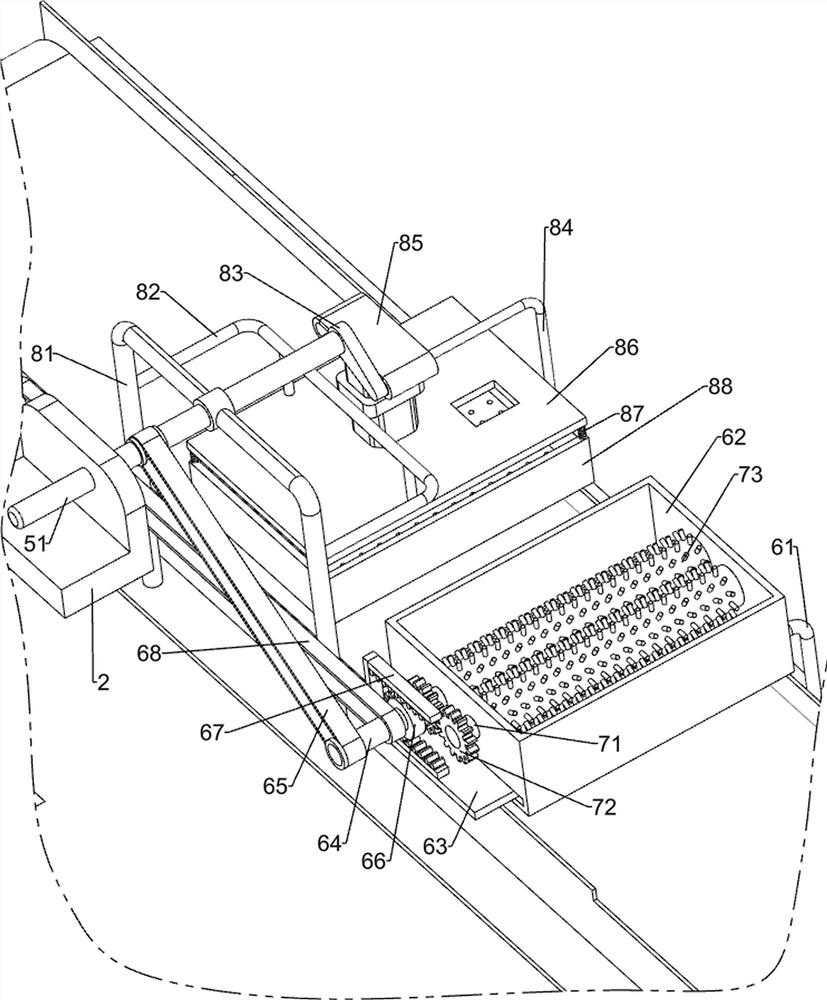

[0029] Conveyor mechanism 5 comprises rotating shaft 51, connects missing tooth 52, rotating rod 53, connecting gear 54, power rod 55, transmission belt group 56, power wheel 57 and conveyor belt 58, is connected with rotating shaft 51 on the servo motor 4, and rotating shaft 51 left end wears Connect the missing tooth 52 through the placement frame 2, and the l...

Embodiment 2

[0033] On the basis of Example 1, such as image 3 Shown, also comprise loosening mechanism 7, loosening mechanism 7 comprises connecting rod 71, drive gear 72 and agitating wheel 73, is connected with connecting rod 71 rotationally on charging frame 62, between connecting rod 71 and rotating shaft 64 A driving gear 72 is connected between them, and the two driving gears 72 mesh with each other, and the rotating shaft 64 and the connecting rod 71 are all connected with a stirring wheel 73 .

[0034] By rotating the rotating shaft 64, the drive gear 72 is meshed with each other, and the stirring wheel 73 in the charging frame 62 is driven to rotate, thereby preventing the seedling soil from agglomerating in the charging frame 62, reducing the number of times the worker cleans the charging frame 62, thereby improving work efficiency.

Embodiment 3

[0036] On the basis of Example 2, such as image 3Shown, also include seeding mechanism 8, and seeding mechanism 8 includes first fixed rod 81, second fixed rod 82, lower pressing block 83, slide bar 84, lower hammer block 85, vibrating block 86, connecting spring 87 and sowing Frame 88, the right support plate 3 is connected with a first fixed rod 81, the rear side of the first fixed rod 81 is connected with a second fixed rod 82, and the rear end of the rotating shaft 51 passes through the first fixed rod 81 and is connected with a lower pressing block 83, The left support plate 3 is connected with a sliding rod 84, the sliding rod 84 is slidably connected with a lower hammer block 85, the lower hammer block 85 is slidably connected with the lower pressing block 83, and the bottom of the second fixed rod 82 is connected with a vibrating block 86 , the lower hammer block 85 is in contact with the vibration block 86, the bottom of the vibration block 86 is connected with a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com