Traction device capable of ensuring no burrs in electrostatic spinning

A traction device and electrospinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of reducing the beauty of finished fibers, inconvenient collection, and reducing work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

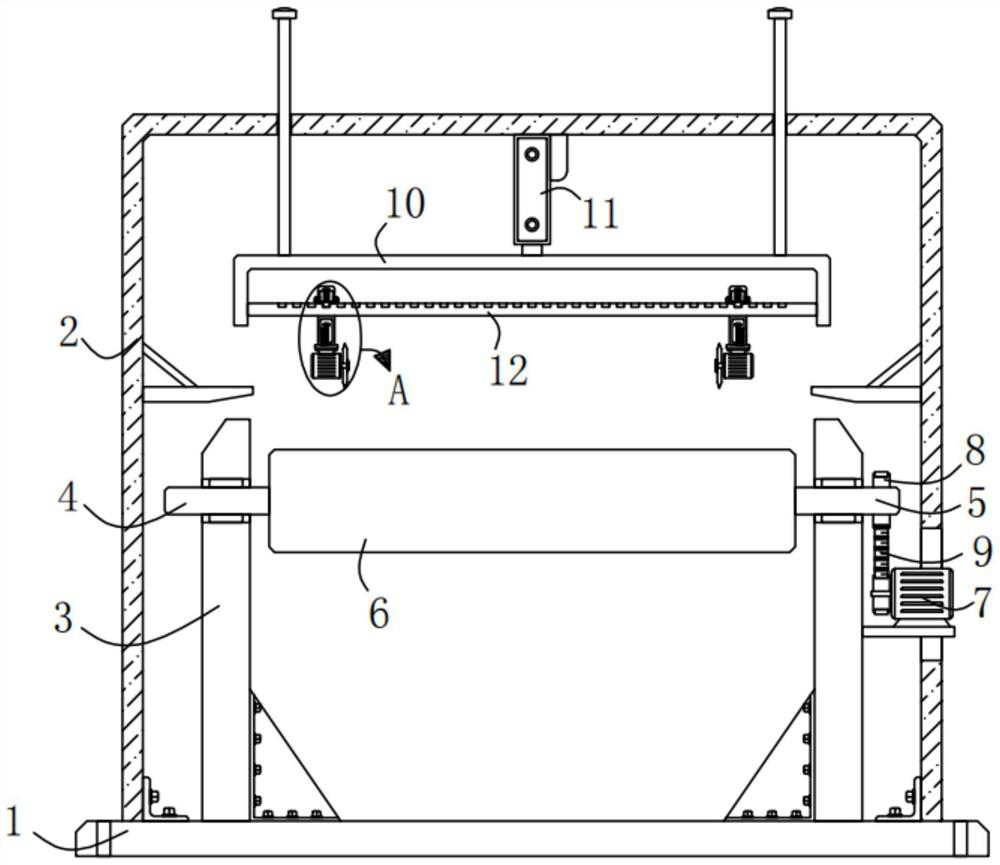

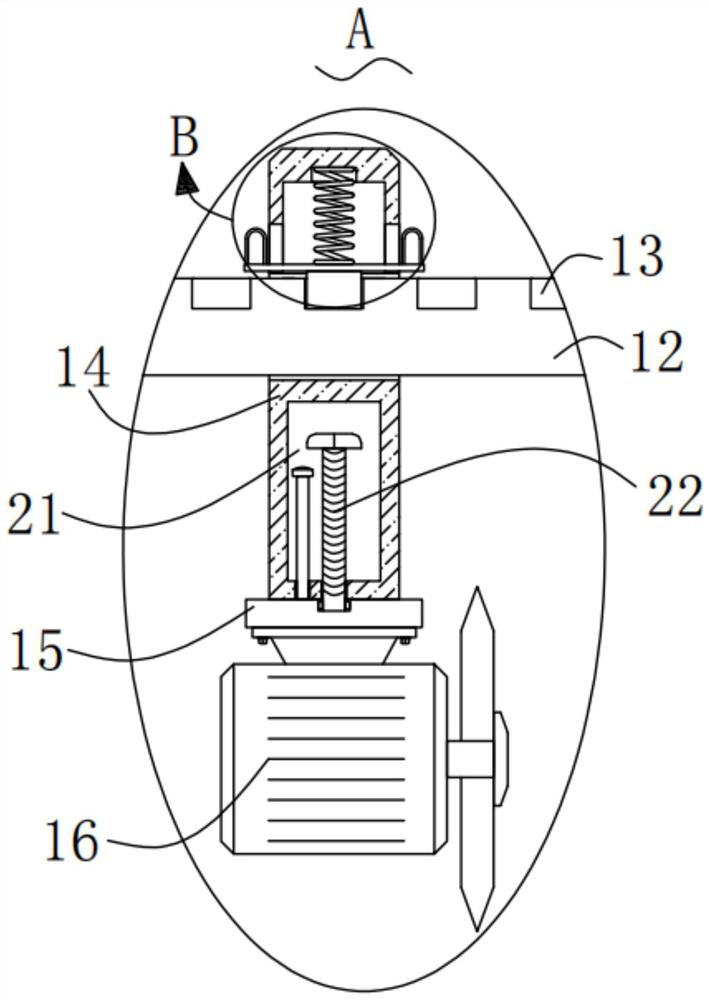

[0025] Please refer to Figure 1-Figure 3 , in the first embodiment of the present invention, the traction device capable of ensuring that electrospinning has no burrs includes: a base 1; a frame 2, which is fixedly installed on the top of the base 1; two supporting side plates 3. The two supporting side plates 3 are fixedly installed on the top of the base 1; the first connecting shaft 4 and the second connecting shaft 5, the first connecting shaft 4 and the second connecting shaft 5 are respectively rotatably installed on two On the support side plate 3; a winding roller 6, the winding roller 6 is arranged between the two support side plates 3; a motor 7, the motor 7 is fixedly installed on the shaft-4 away from the On the support side plate 3; two synchronous pulleys 8, the two synchronous pulleys 8 are respectively fixedly sleeved on the output shaft of the motor 7 and the second shaft 5; a synchronous belt 9, the synchronous belt 9 is set on the two synchronous pulleys 8...

no. 2 example

[0040] Based on the traction device provided by the first embodiment of the present application that can ensure no burr in electrospinning, the second embodiment of the present application proposes another traction device that can ensure burr-free electrospinning. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0041] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

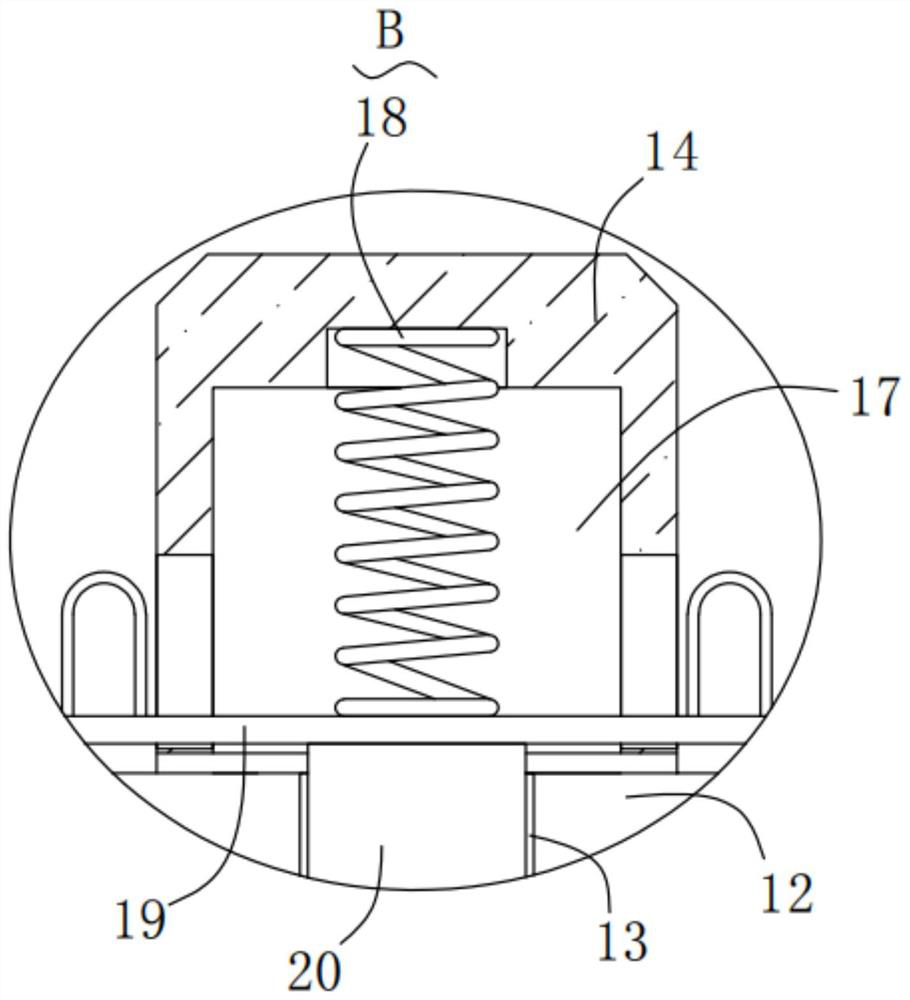

[0042] Please refer to Figure 4-Figure 5 , in the second embodiment of the traction device proposed by the present invention capable of ensuring no burrs in electrospinning: the ends of the connecting shaft 1 4 and the connecting shaft 2 5 that are close to each other are in contact with the winding roller 6, The connecting shaft 1 4 and the connecting shaft 2 5 are all provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com