Fish feed production fermentation and material taking device

A technology of reclaiming device and fish feed, which is applied in the directions of biochemical cleaning device, enzymology/microbiology device, feed, etc., can solve the problems of waste, physical and energy consumption, and feed residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

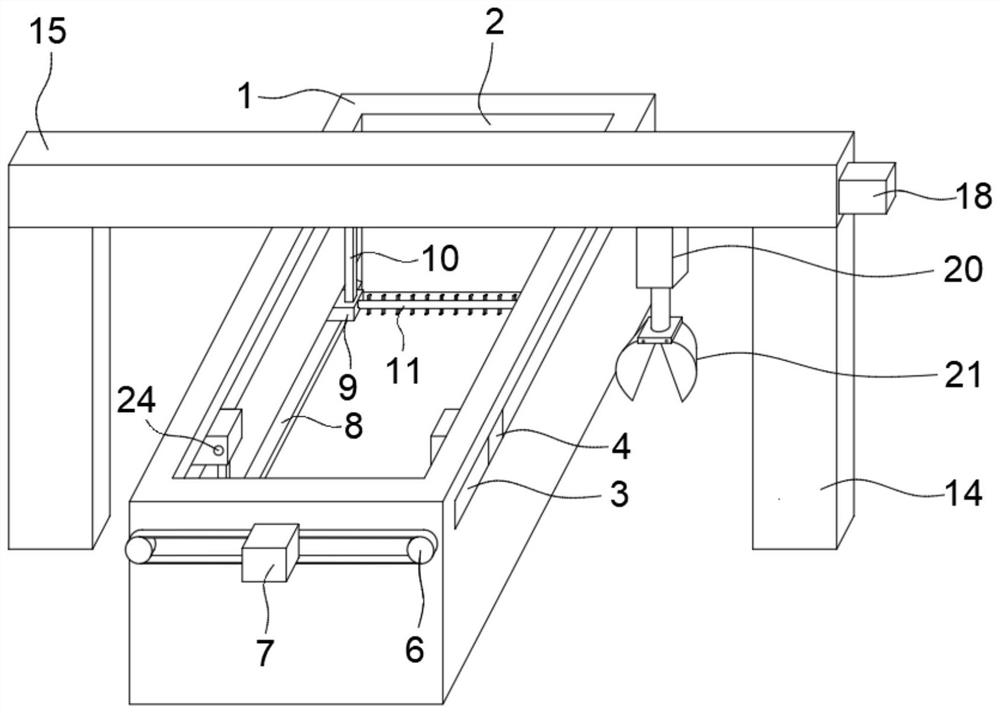

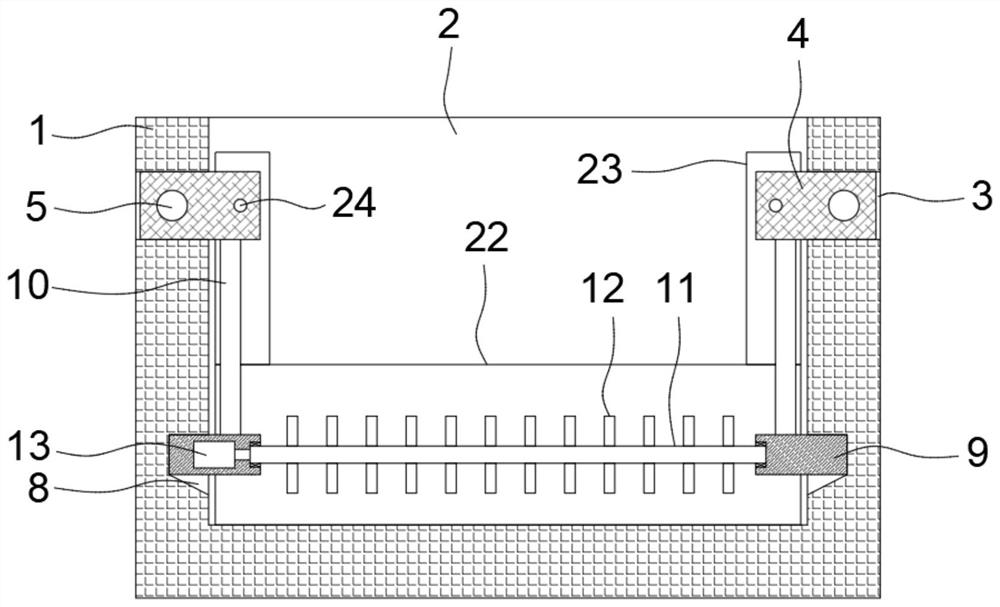

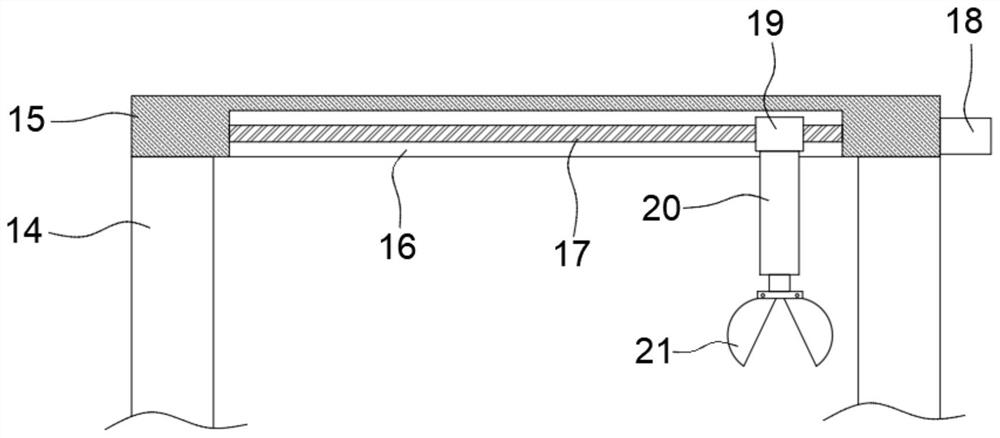

[0023] refer to Figure 1-3 , a kind of fish feed production fermentation feeding device, comprises fermenter 1, fermenter 1 is provided with fermenter 2, fermenter 2 left and right side inner wall and the position close to fermenter 2 notch all is vertically provided with sliding slot 3, Two-way threaded rods 5 are connected to the front and rear inner walls of the two sliding ports 3 for common rotation. The front ends of 5 are all fixedly sleeved with pulleys 6, and the front end of the fermentation tank 1 is fixedly installed with a first motor 7 between the two pulleys 6. The first motor 7 is a forward and reverse motor, and the output of the first motor 7 The end and the two pulleys 6 are jointly set with a transmission belt, and the two bidirectional threaded rods 5 are connected by a belt transmission, and the two bidirectional threaded rods 5 can be driven by the first motor 7 to rotate synchronously.

[0024] Both two-way threaded rods 5 are correspondingly threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com