Method and device for separating coal and gangue underground by using high-speed belt conveyor

A belt conveyor and conveyor technology, applied in solid separation, chemical instruments and methods, classification, etc., can solve problems such as waste of land resources, environmental hazards, mudification, etc., achieve significant economic and social benefits, and reduce work The effect of small amount and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

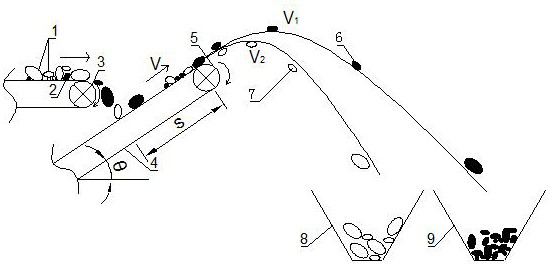

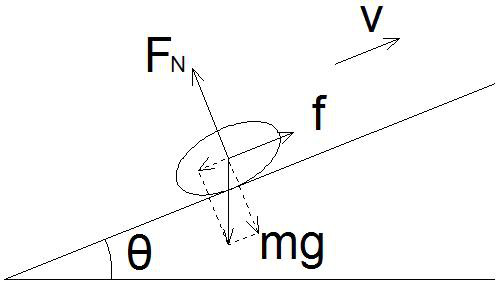

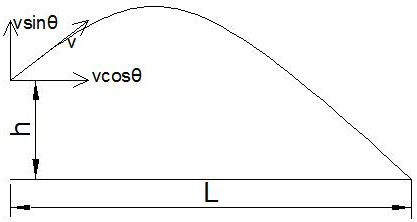

[0054] Such as figure 1 As shown, the present invention includes a horizontal constant speed belt conveyor and an inclined high speed belt conveyor. Among them, the horizontal constant-speed belt conveyor 2 transports the raw coal 1 from the working face, and when the raw coal 1 moves to the right to the material outlet 3 of the horizontal constant-speed belt conveyor, it will fall; the inclined high-speed belt conveyor 4 is located below the horizontal constant-speed belt conveyor 2. When the raw coal 1 falls on the inclined high-speed belt conveyor 4, it will slide relative to the conveyor belt. acceleration. Due to the different friction coefficients between coal, gangue and the conveyor belt, the upward frictional forces on the conveyor belt are different, so the accelerations of the two are also different; There are 5 material outlets of the type conveyor, and the coal and the gangue have different speeds; at the next moment, the coal and the gangue will both do obliqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com