Automatic pre-mixing self-compacting cement soil fertilizer groove backfilling system and construction method

A cement-soil, self-compacting technology, applied in chemical instruments and methods, filling, cement mixing devices, etc., can solve the problems of low construction quality, long construction period, narrow construction area, etc., to improve construction automation and shorten mixing. time, the effect of reducing on-site pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

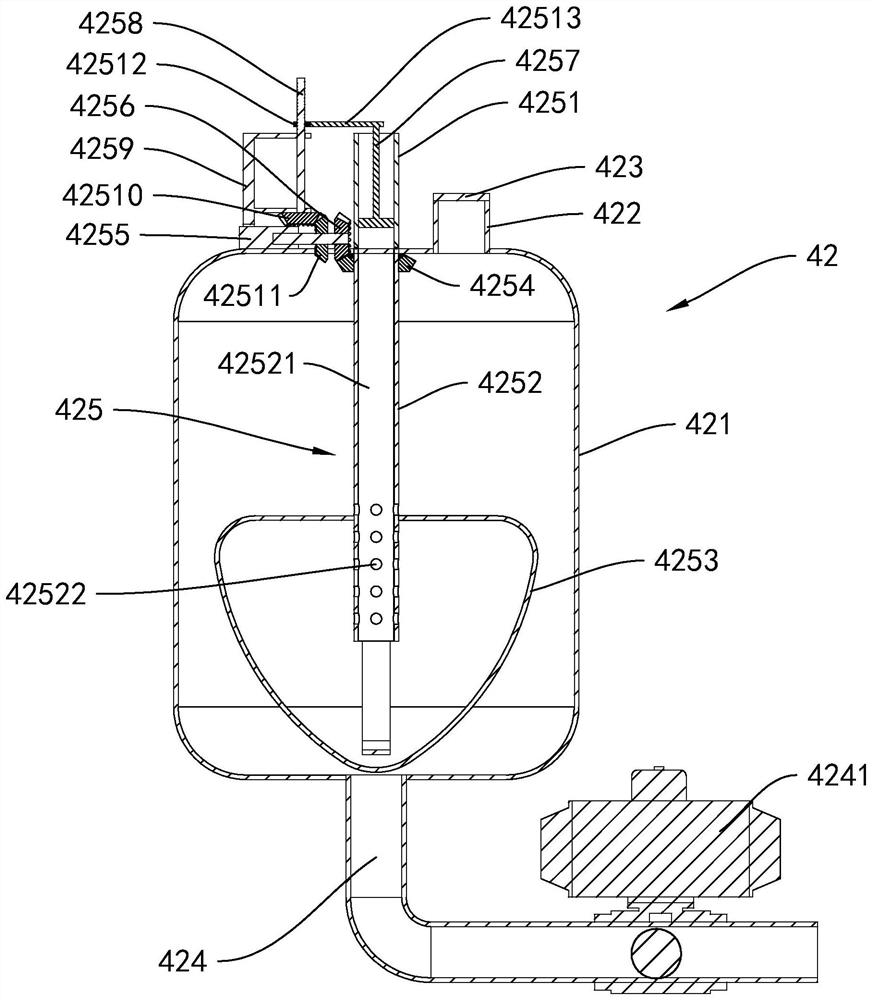

[0043] The following is attached Figure 1-5 The application is described in further detail.

[0044] The embodiment of the present application discloses an automatic ready-mixed self-compacting cement-soil fertilizer tank backfilling system.

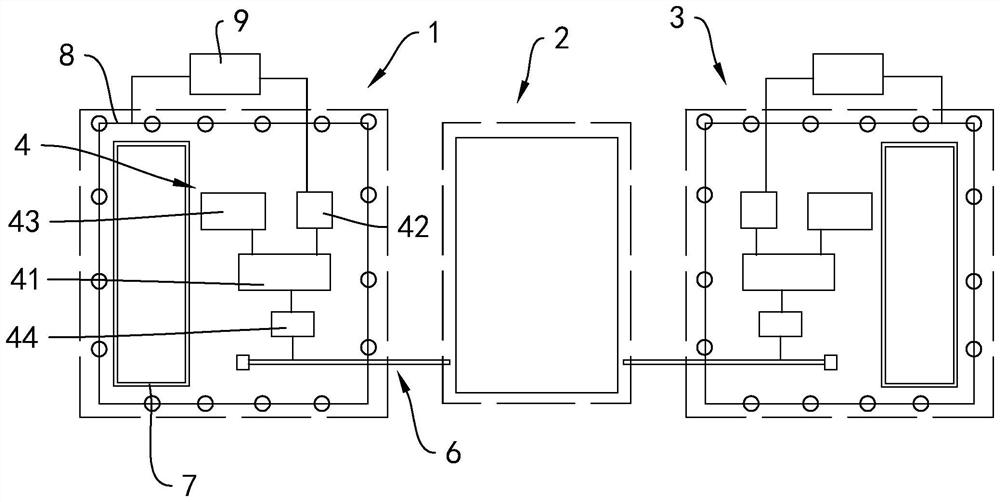

[0045] refer to figure 1 The automatic ready-mixed self-compacting cement-soil fertilizer tank backfill system includes the first positive construction area 1 of the CFG pile construction phase, the fertilizer tank backfill construction area 2 of the fertilizer tank backfill construction phase, and the second positive construction area 3 of the slope protection pile construction phase, The ground elevations of the first ongoing construction area 1 , the fertilizer tank backfilling construction area 2 and the second ongoing construction area 3 are all lower than the elevation of the horizontal ground.

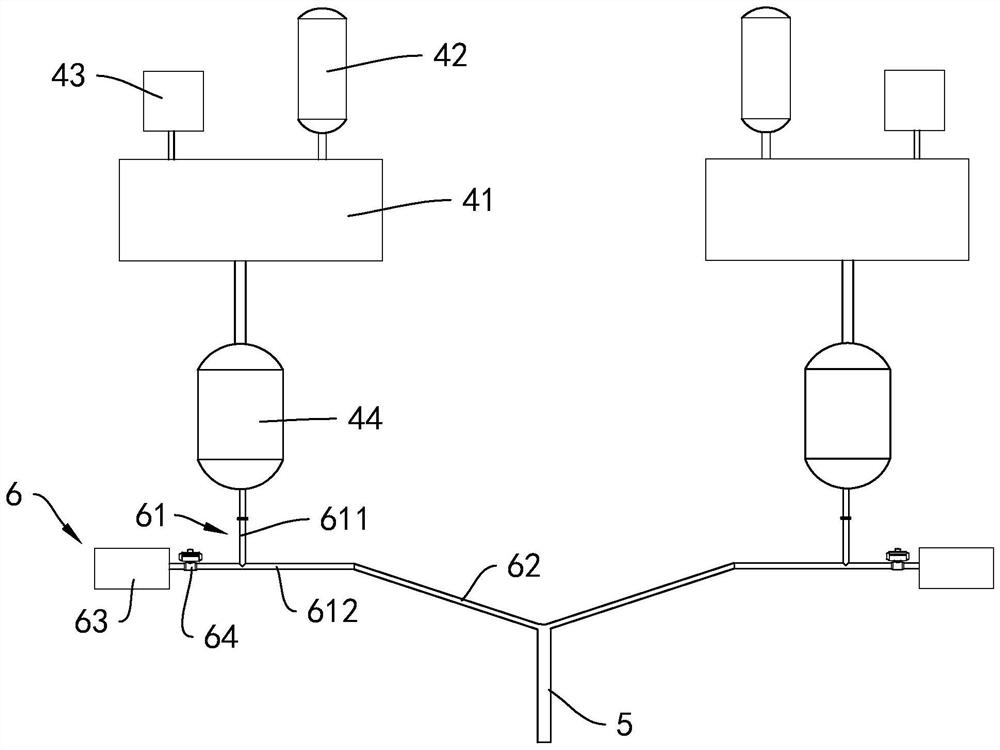

[0046] refer to figure 1 , figure 2 , cement and soil processing systems 4 are installed in the first construction area 1 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com