Automatic detection device for factory qualification of mobile phone lithium battery

An automatic detection device and lithium battery technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of low detection efficiency, waste of manpower, and waste of detection time, so as to improve detection efficiency, increase detection efficiency, and not Easy to stay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

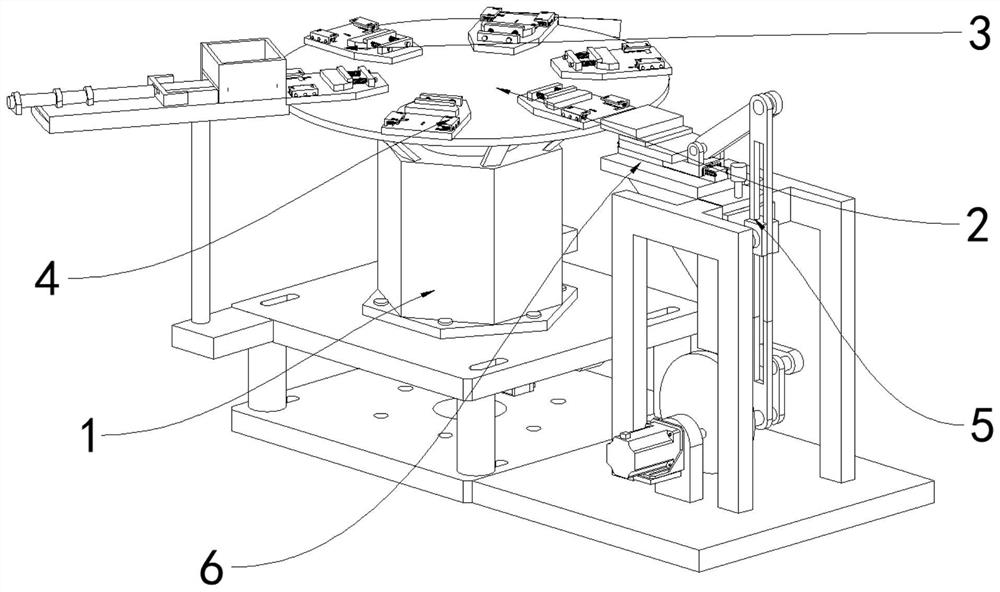

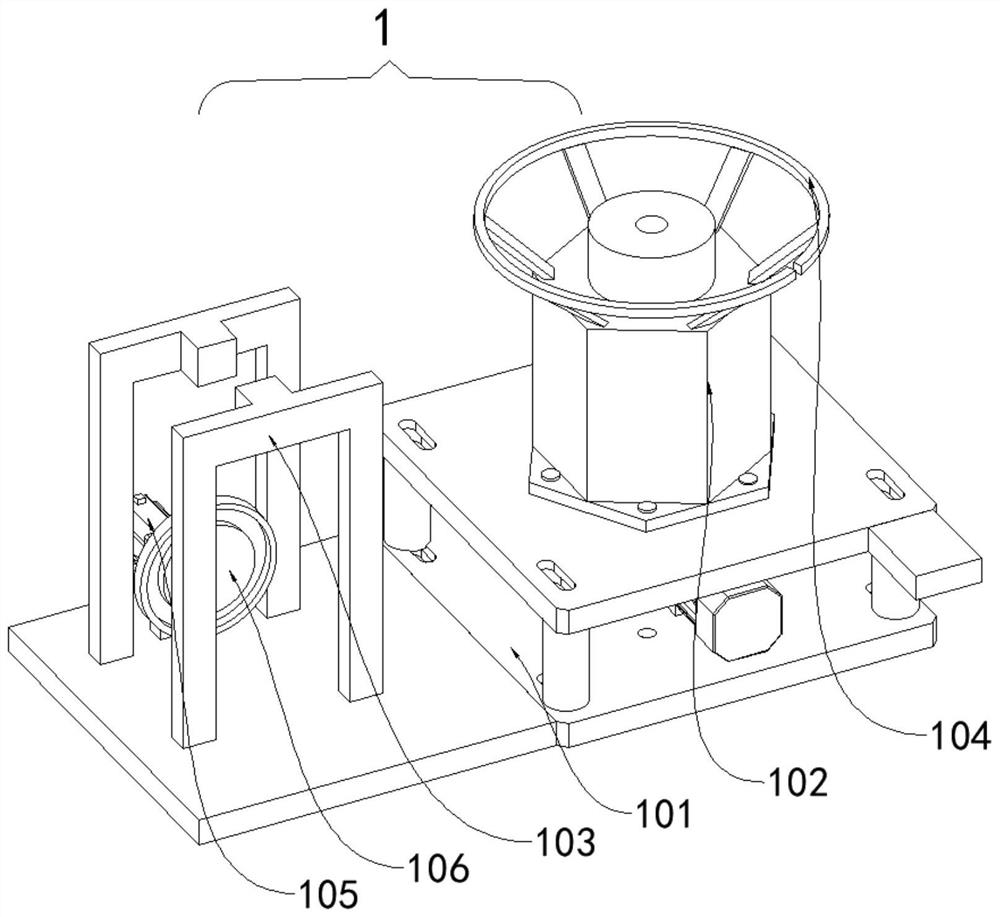

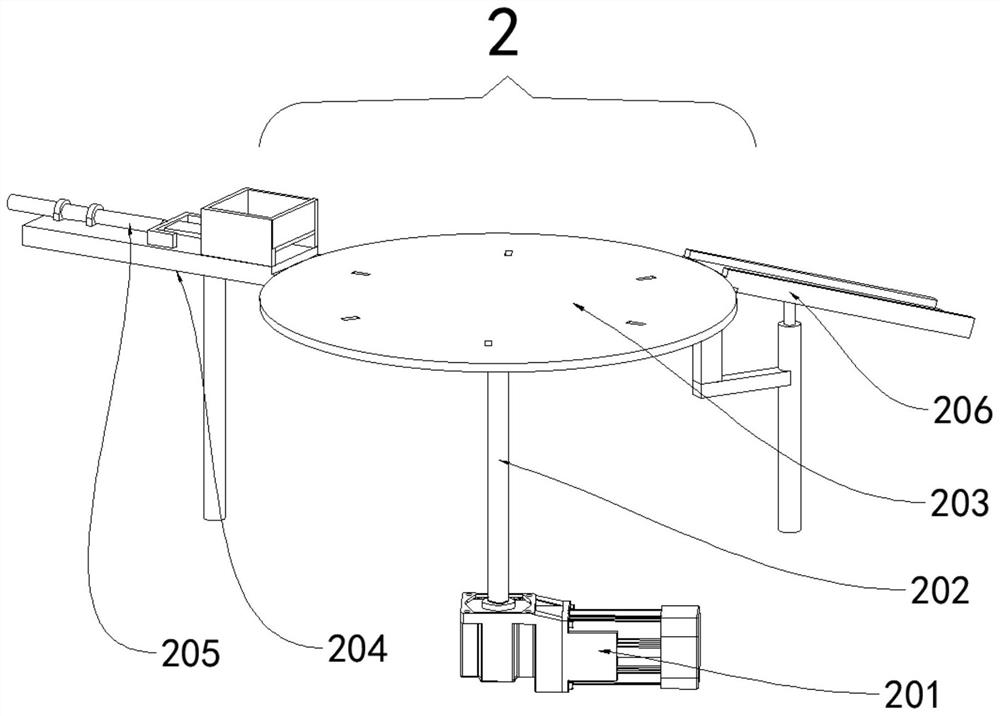

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides a mobile phone lithium battery factory qualification automatic detection device, which includes an external support mechanism 1; a transmission mechanism 2 is fixedly installed on the left side of the top of the external support mechanism 1; and six linkage mechanisms are arranged on the top of the transmission mechanism 2 in a circular arrangement. 3. The linkage mechanism 3 includes a fixed seat 301, a connecting rack 302, an L-shaped groove 303, a stopper 304, a sliding rod 305, a sliding block 306 and a buckle 307, and the middle position of the top of the fixed seat 301 is slidingly provided with connecting teeth Bar 302, the top of the left end of the connecting rack 302 is fixedly provided with a sliding block 306, the top of the left end of the fixed seat 301 is fixedly provided with a stopper 304, the front and rear sides of the stopper 304 are slidably provided with two slide bars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com