Steel wire cutting machine and using method thereof

A cutting machine and steel wire technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient cleaning and increased difficulty of cleaning for staff, and achieve the effect of sensitive movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

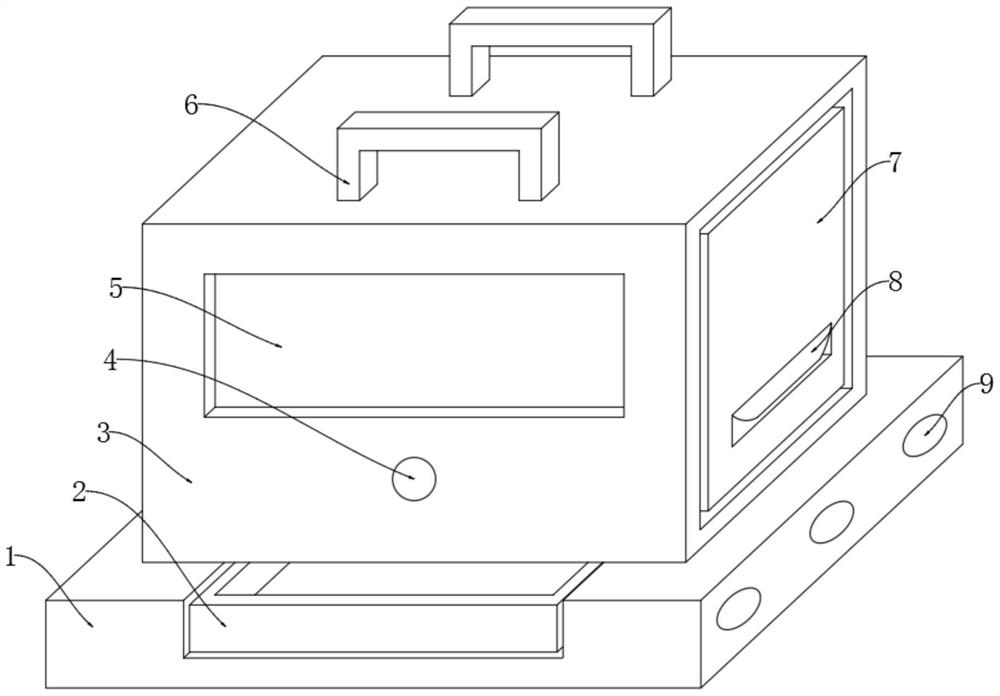

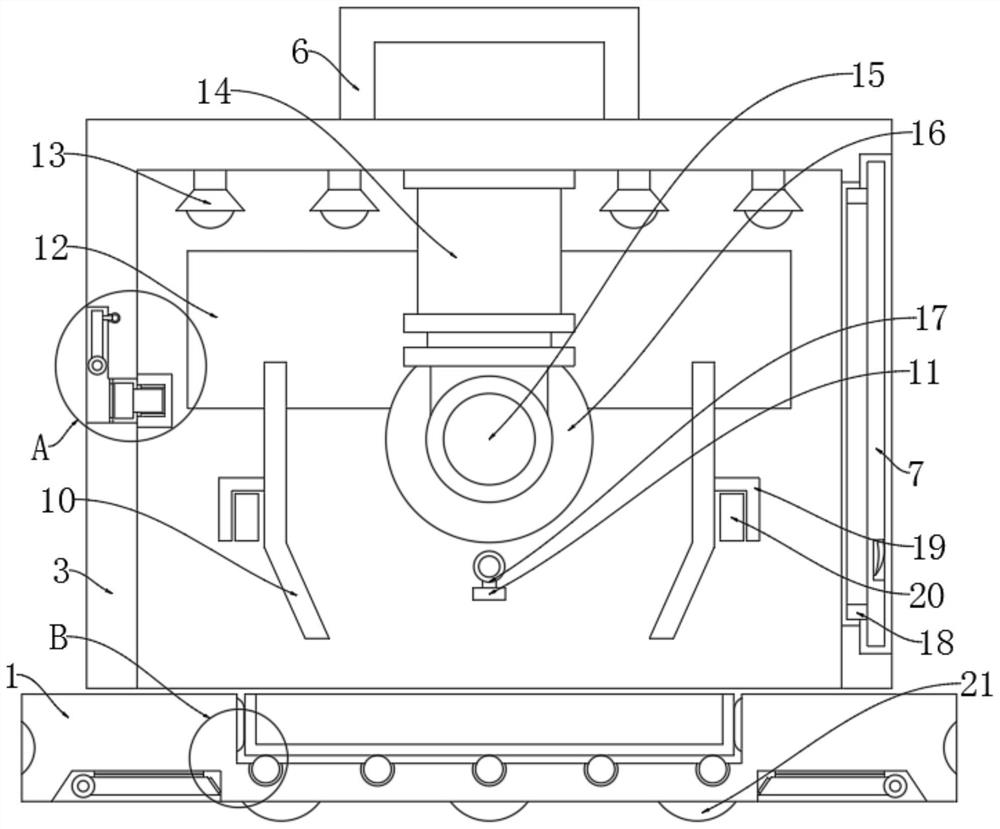

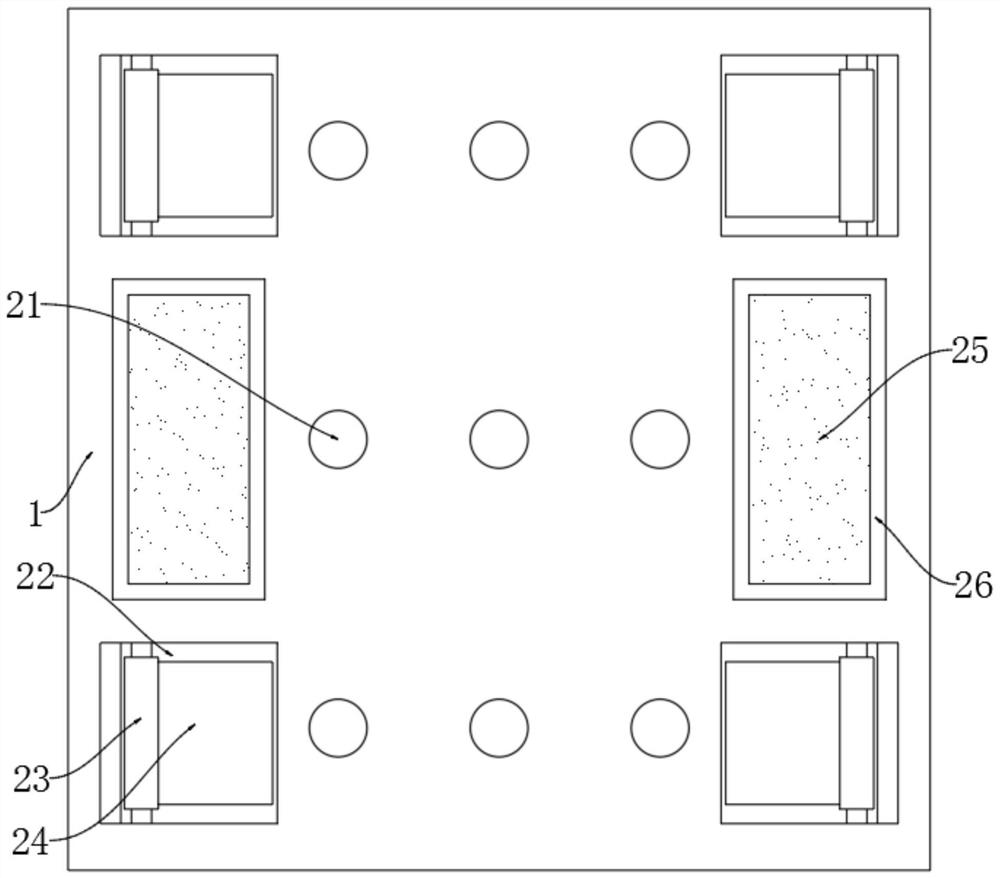

[0027]SeeFigure 1-5One embodiment of the present invention is provided: a steel wire cutter comprising a fixed lower chamber 1, and the fixed upper block 1 is provided above the lower block 1, and the upper end of the bottom block 1 is provided with a receiving box placement slot. 35. The inside of the receiving box placed groove 35 is provided with a residue receiving box 2, and the sliding ball 34 is provided below the residue receiving box 2, and the sliding ball 34 is provided with several, the sliding ball 34 and the fixed under block 1 The card slot rotates, so that the sliding ball 34 is more secure to the fixed lower block 1, and both sides of the residue receiving box 2 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com