High-precision scale synchronous falling type thread rolling equipment

A blanking, high-precision technology, applied in the direction of threaded products, metal processing equipment, manufacturing tools, etc., can solve the problems of automatic blanking, inaccurate thread rolling precision, etc., to achieve the goal of improving accuracy and speeding up efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

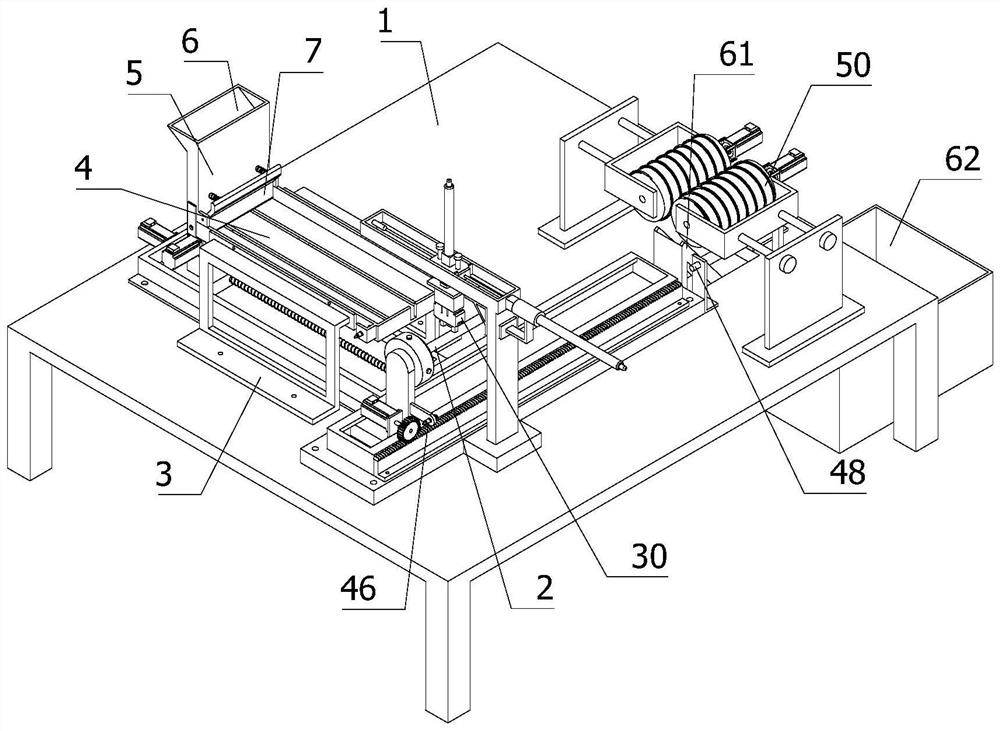

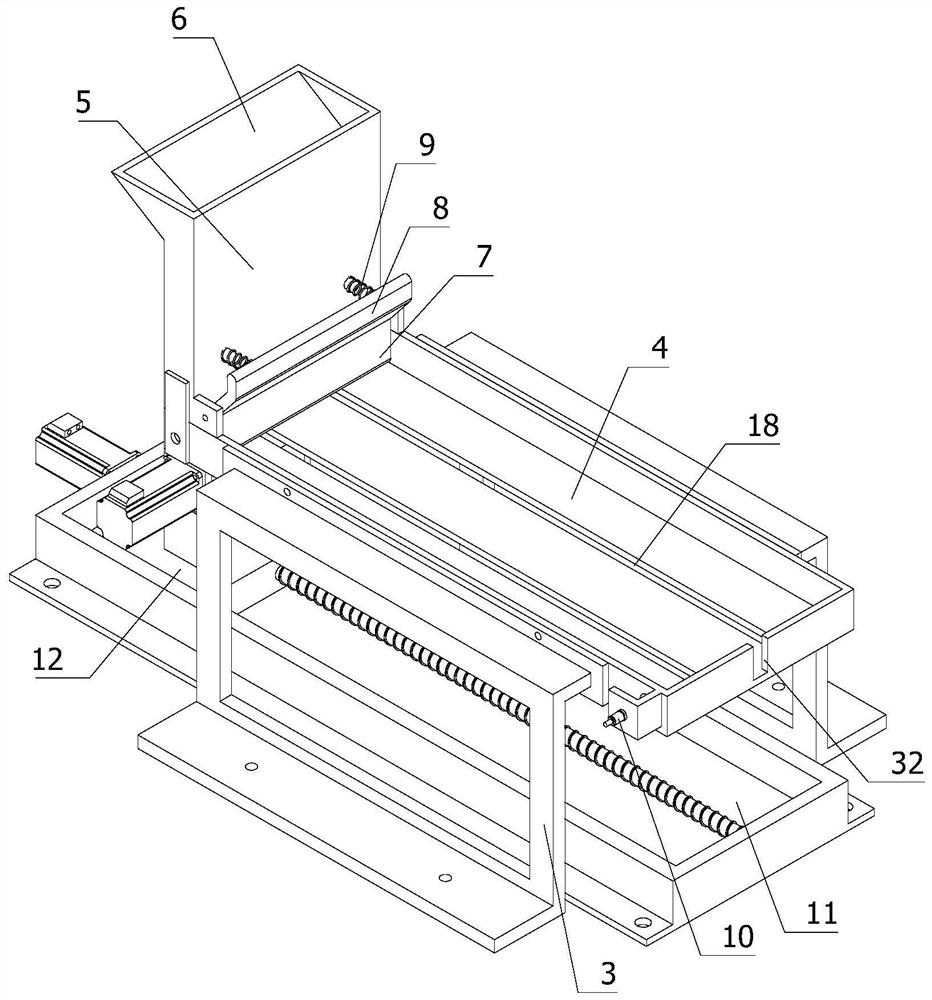

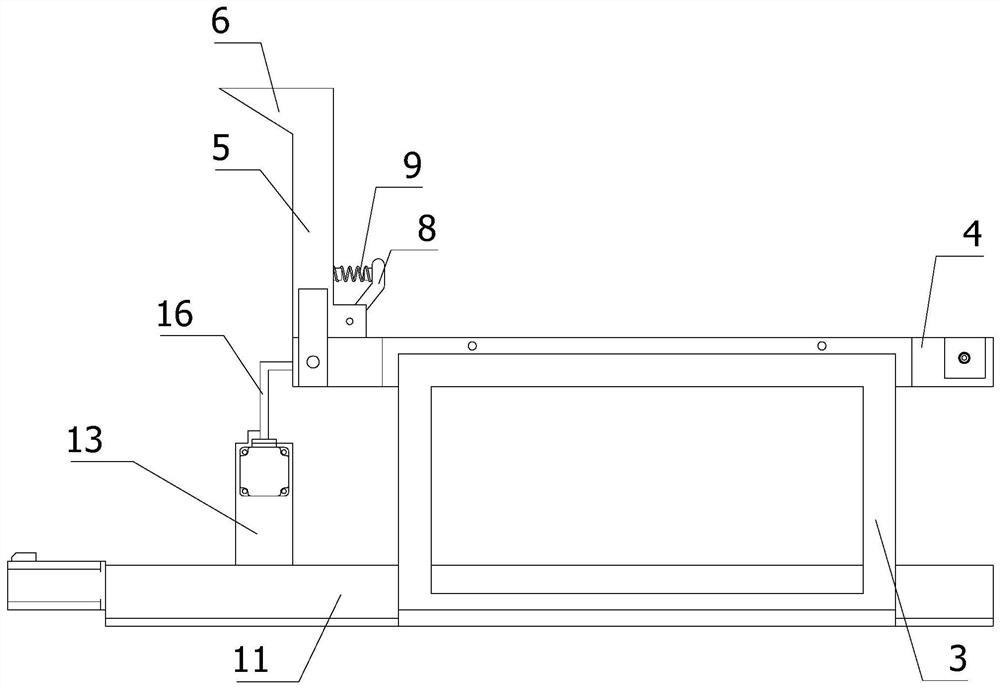

[0077] refer to Figure 1 to Figure 10 As shown, a high-precision scale synchronous blanking type thread rolling equipment includes: workbench 1;

[0078] The discharging assembly is used to place batches of metal rods 2, and the discharging assembly is arranged on the top of the workbench 1;

[0079] The push assembly is used to push the metal rod 2 on the discharge assembly, and the push assembly is arranged on the discharge assembly;

[0080] The material-moving component is used to move the metal rod 2, and the material-moving component is arranged on the top of the workbench 1, and the material-moving direction of the material-moving component is also perpendicular to the pushing direction of the pushing component;

[0081] The positioning component is used for positioning the metal rod 2, and the positioning component is arranged on the material moving component;

[0082] The grabbing component is used to grab the metal rod 2 on the discharging component to the positio...

Embodiment 2

[0126] Compared with Embodiment 1, in this embodiment, the thread rolling assembly includes:

[0127] Two rolling rollers 50 are provided, and the two rolling rollers 50 are arranged symmetrically above the workbench 1, and each rolling roller 50 is rotatably arranged on a U-shaped frame 51;

[0128] Two support plates 52 are provided, and the two support plates 52 are all fixedly arranged on the top of the workbench 1, and each support plate 52 is respectively located on the outside of each U-shaped frame 51, and the closed end of each U-shaped frame 51 has two Each side is provided with a stabilizing bar 53 through the corresponding support plate 52, and an anti-off disc 54 is also provided at the outward end of each stabilizing bar 53;

[0129] Two rotating motors 55 are provided for driving each rolling roller 50. The output end of each rotating motor 55 is connected with one end of the corresponding rolling roller 50 by a coupling. Each rotating motor 55 All are fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com