Long and flat workpiece knurling tool

A tooling and knurling technology is applied in the field of knurling tooling for long and flat workpieces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

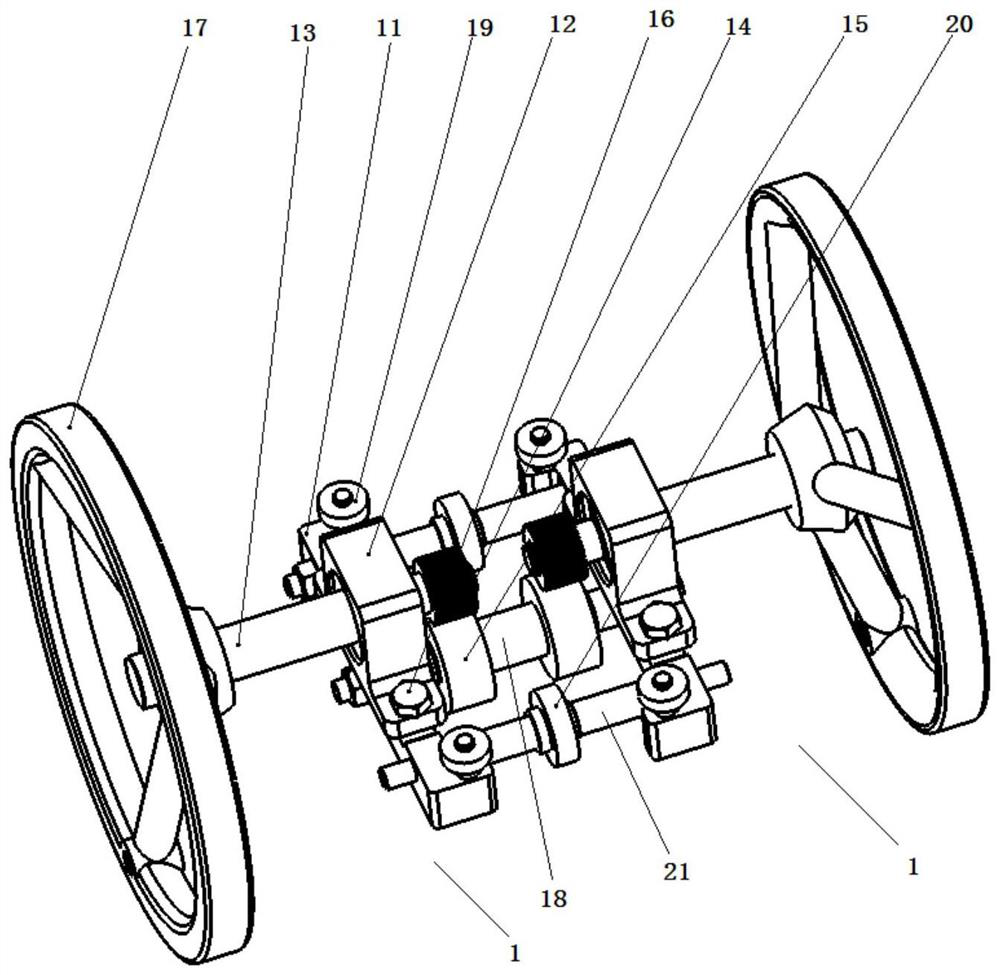

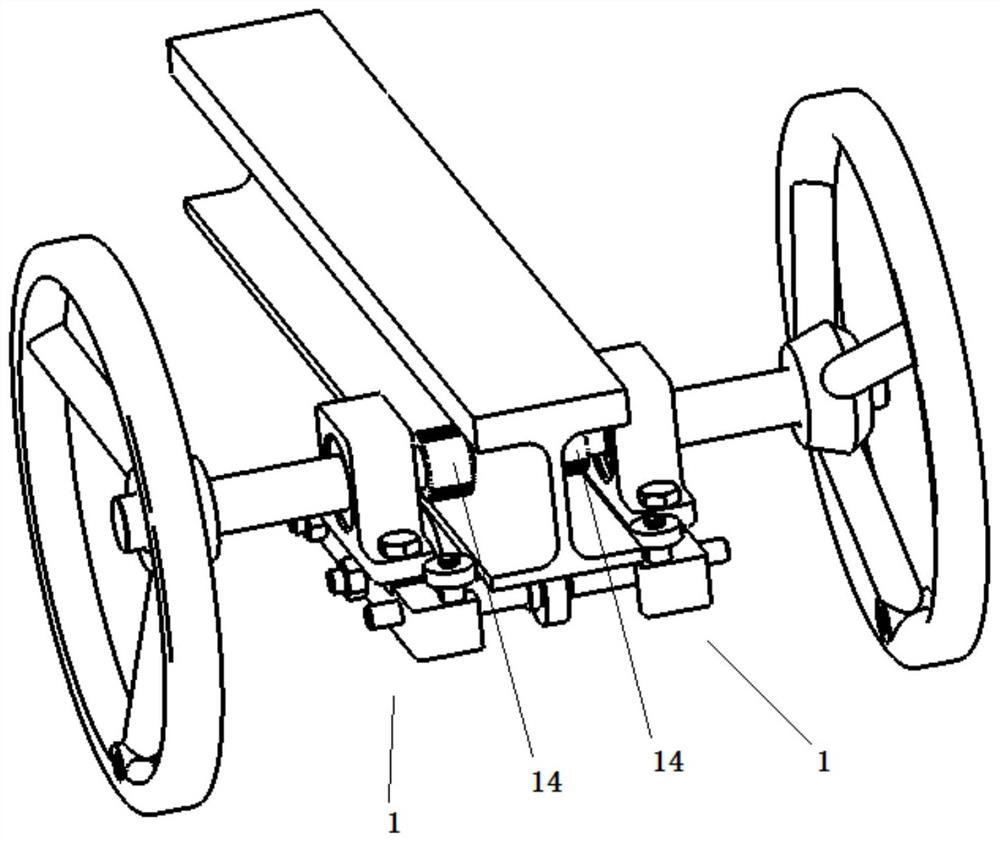

[0020] The knurling tool for a long and flat workpiece disclosed in this embodiment is described as a symmetrically arranged structure that can simultaneously perform knurling on both sides of the workpiece. The structure and use of one side can be fully disclosed and reasoned through this embodiment It can be concluded that no further detailed description of the structure on one side will be made in this embodiment, such as figure 1 and figure 2 As shown, the knurling tooling includes two sets of tooling mechanism main bodies 1 that are symmetrically connected. The structural positional connection relationship of each part will be described in detail below in conjunction with the accompanying drawings.

[0021] The upper pressure seat 12 is arranged on the lower support 11 through a height adjustment struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com