3D printing powder cleaning curb chain and powder cleaning method

A 3D printing and powder cleaning technology, which is applied in the field of 3D printing, can solve the problems of difficult powder cleaning, low powder cleaning efficiency and lack, etc., and achieve the effect of expanding the scope of application of products and improving the efficiency of powder cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A 3D printing powder cleaning chain and a powder cleaning method.

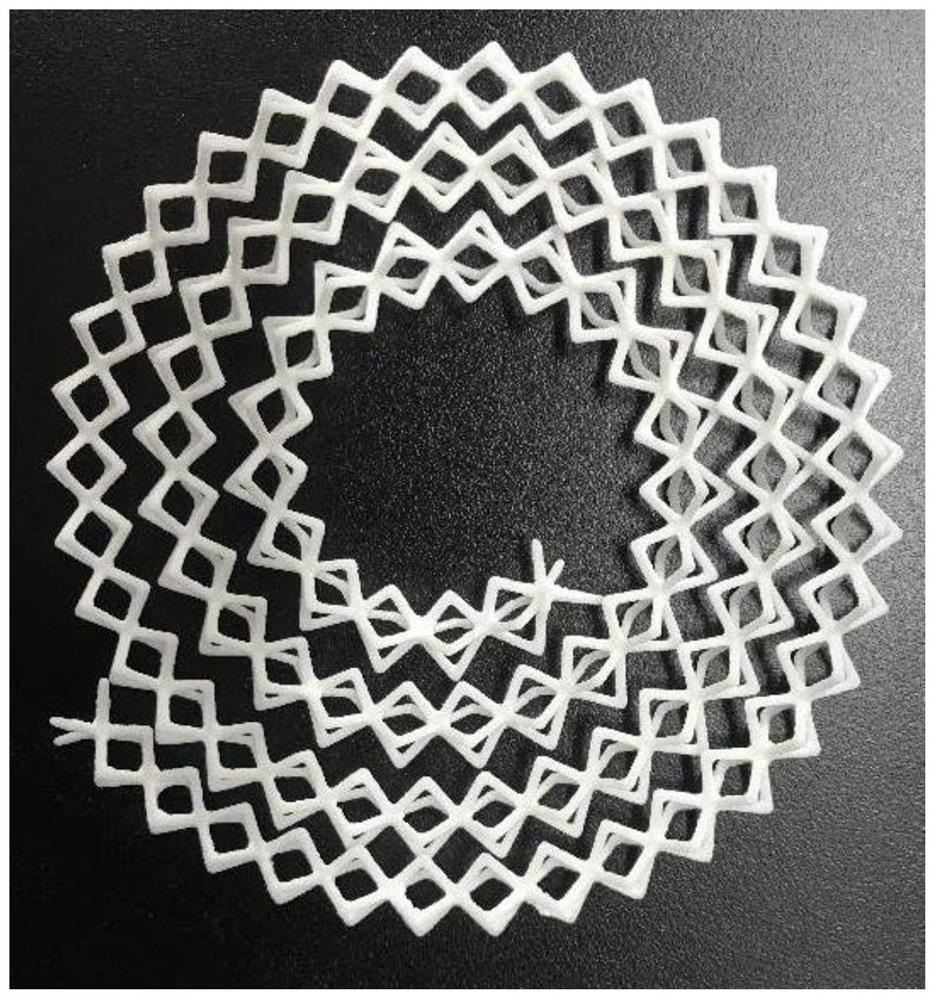

[0027] (1) in Figure 11 In the target product shown, use 3D software to design a suitable chain structure. In this embodiment, the target product is a shell with two ports, and there are two chains inside the product. Just import the designed structural model into a 3D printer. Print.

[0028] (2) The 3D printer adopts SLS selective laser sintering printer.

[0029] (3) The 3D printing of this box uses SLS selective laser sintering technology, and the printing raw material is nylon powder, and the laser is used to scan and irradiate the powder layer by layer under the control of the computer to achieve sintering and bonding of thermoplastic powder, and layer by layer accumulation to achieve forming.

[0030] (4) The nylon powder used in the 3D printing semi-enclosed box structure is a powder with a particle size of 100 microns, and the sintering temperature of the thermoplastic material is 170°C.

...

Embodiment 2

[0034] A 3D printing powder cleaning chain and a powder cleaning method.

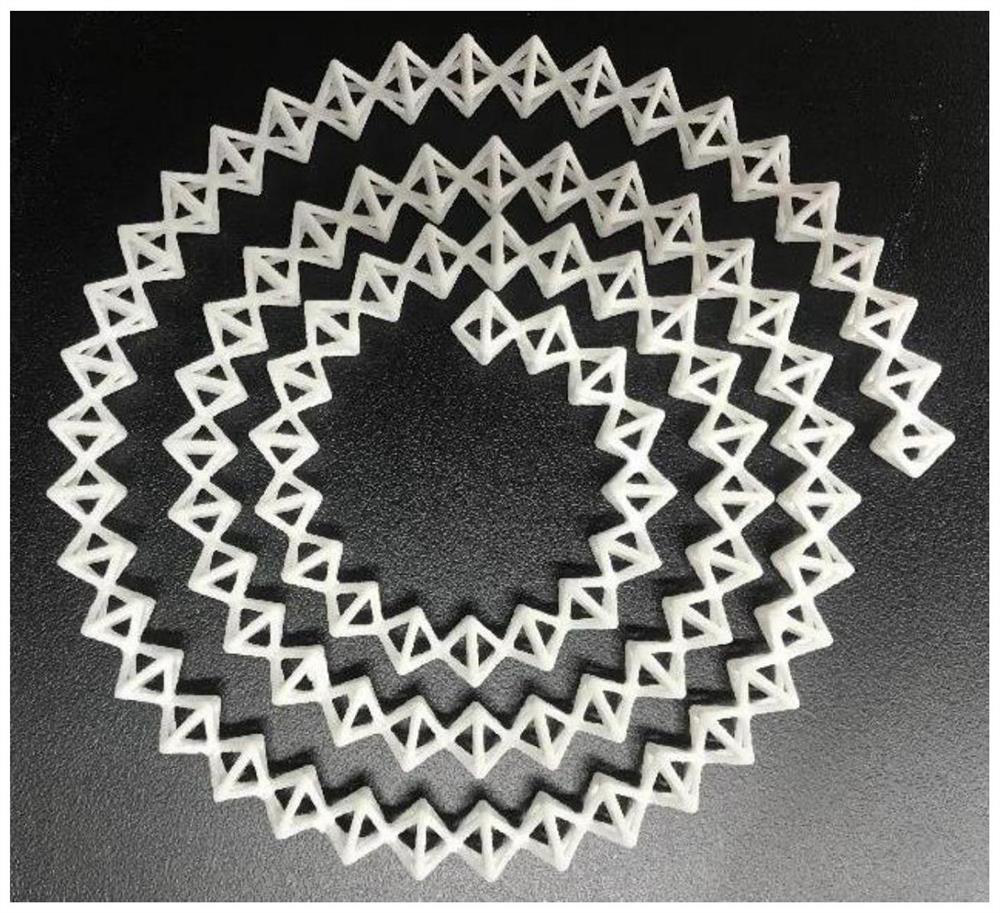

[0035] (1) in Figure 12 For the target product shown, design a suitable chain structure in the 3D software, and import the designed structure into the 3D printer to print.

[0036] (2) The 3D printer adopts SLS selective laser sintering printer.

[0037] (3) The 3D printing of this sphere uses SLS selective laser sintering technology. The printing raw material is PP powder. The laser is used to scan and irradiate the powder layer by layer under the control of the computer to realize the sintering and bonding of thermoplastic powder, and the layer-by-layer accumulation realizes molding. .

[0038] (4) The PP powder used in the 3D printing spherical structure is a powder with a particle size of 100 microns, and the sintering temperature of the thermoplastic material is 120°C.

[0039] (5) Take out the product from the printer and remove the powder on the surface of the product.

[0040] (6) Slowly pu...

Embodiment 3

[0042] A 3D printing powder cleaning chain and a powder cleaning method.

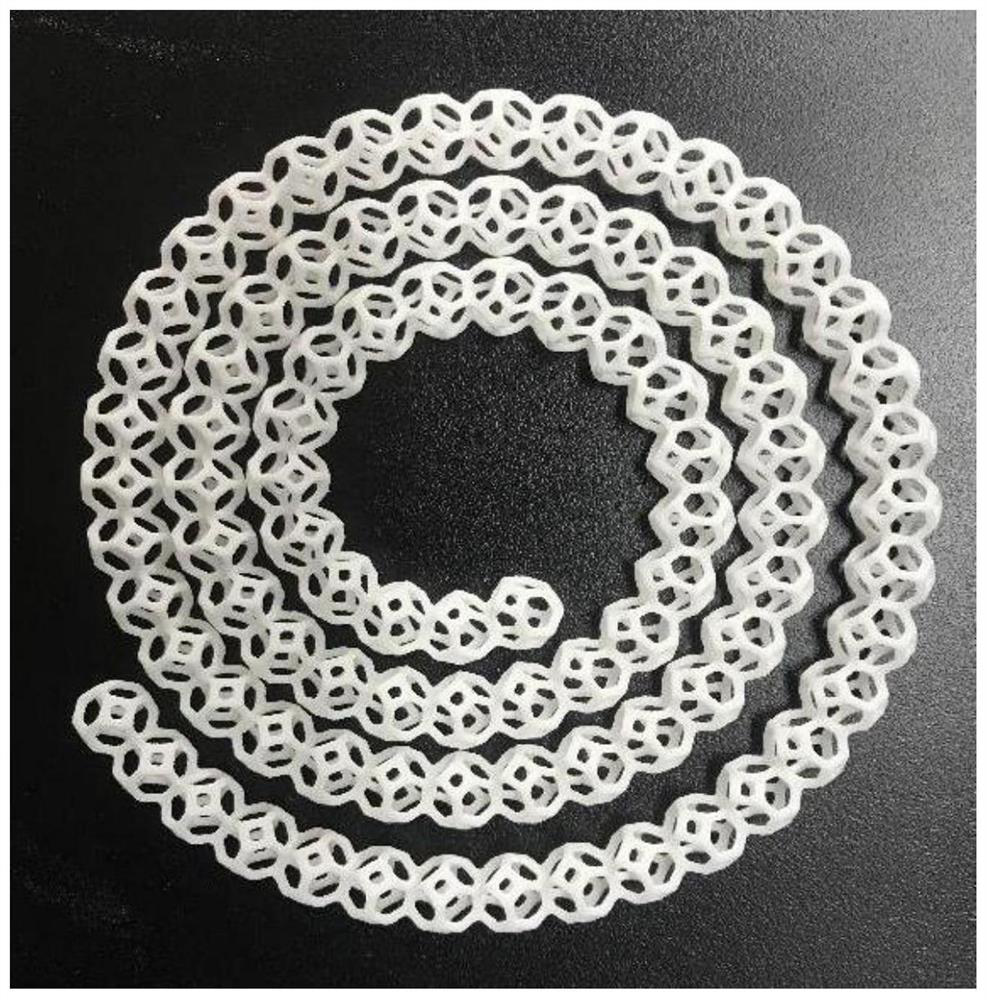

[0043] (1) First in Figure 13 For the target product shown, design a suitable chain structure in the 3D software, and import the designed structure into the 3D printer to print.

[0044] (2) The 3D printer adopts SLS selective laser sintering printer.

[0045] (3) The 3D printing of this bottle body uses SLS selective laser sintering technology. The printing material is TPU powder. The laser is used to scan and irradiate the powder layer by layer under the control of the computer to realize the sintering and bonding of thermoplastic powder, and the layer-by-layer accumulation realizes forming.

[0046] (4) The TPU powder used in the 3D printed bottle structure is a powder with a particle size of 100 microns, and the sintering temperature of the thermoplastic material is 120°C.

[0047] (5) Take out the product from the printer and remove the powder on the surface of the product.

[0048] (6) Slowly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap