Method for cleaning away small-size pore powder of PEEK material 3D printing product

A 3D printing, small-scale technology, applied in the field of 3D printing, which can solve the problems of inability to achieve complete removal, waste of manpower and energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 provides a method for cleaning PEEK powder according to the method described in this patent. The specific plan is as follows:

[0035] Dimethyl sulfoxide and ethanol are used as raw materials to form a solution with a certain ratio, and the volume fraction is 4:1, and then the capillary tube with the bonded PEEK powder is put into it, and the powder is washed by ultrasonic vibration at a certain temperature. out.

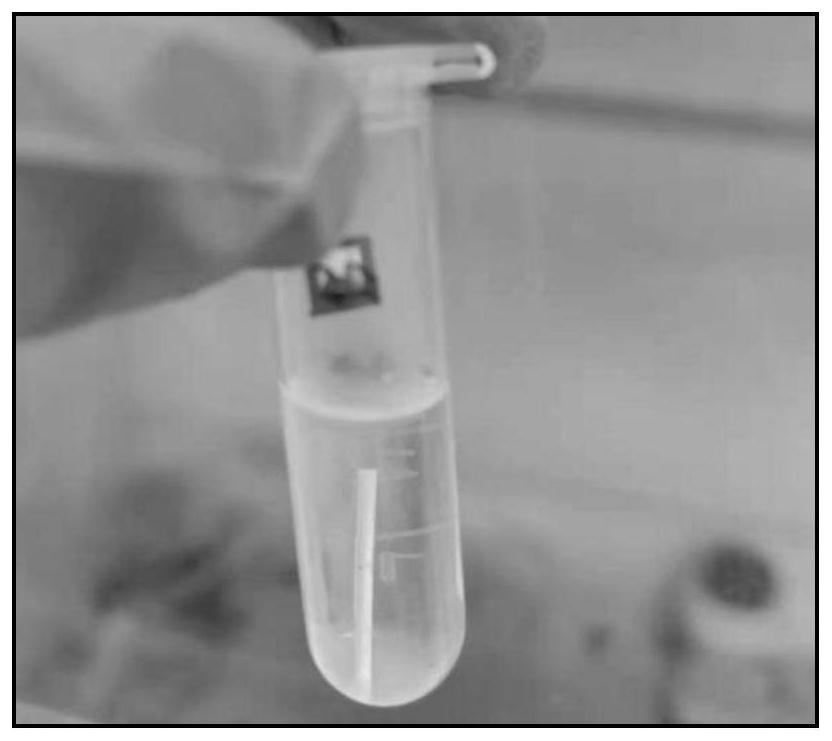

[0036] Under normal pressure, the ultrasonic cleaning time is 10 minutes, and the temperature is 25°C. The final performance is that the bonded powder is cleared out, such as figure 2 shown in .

Embodiment 2

[0038] This embodiment provides a method for cleaning PEEK powder. Compared with Example 1, this example differs in that:

[0039] The cleaning liquid was replaced with ethanol, and the others remained unchanged.

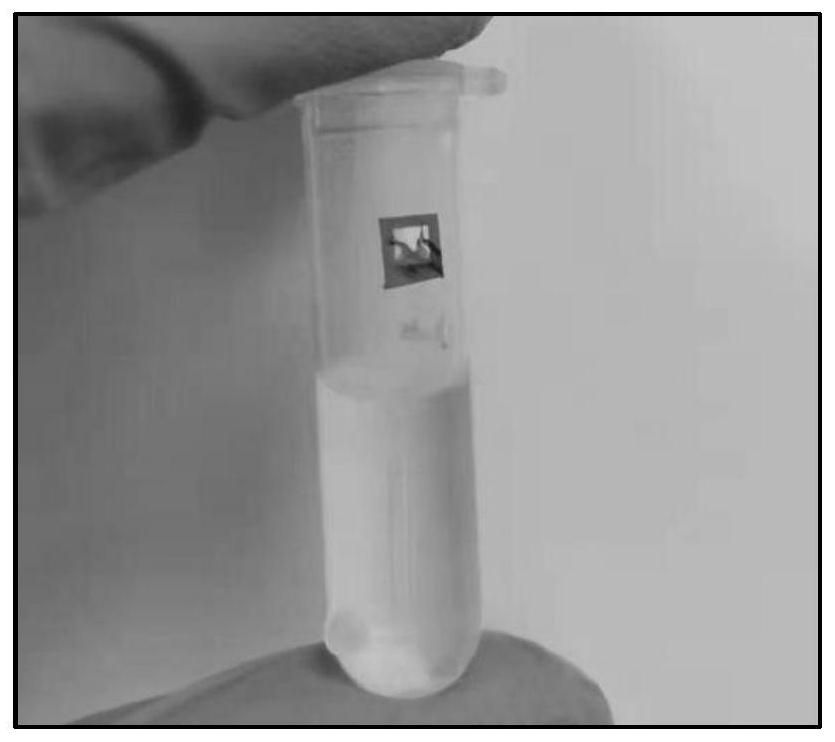

[0040] After cleaning, the powder block still exists, a small amount of powder flakes off, and the cleaning effect is poor, such as image 3 .

Embodiment 3

[0042] This embodiment provides a method for cleaning PEEK powder. Compared with Example 1, this example differs in that:

[0043] Change the cleaning liquid to cyclohexanone, and treat the sample as PEEK powder.

[0044] After cleaning, the powder block still exists, part of the powder flakes off, and the cleaning effect is poor, such as Figure 5 No. 1 test tube.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap