Forming cylinder powder discharging device used for additive manufacturing equipment

An additive manufacturing and forming cylinder technology, applied in the field of additive manufacturing, can solve the problem of time-consuming and laborious cleaning of powder, and achieve the effect of reducing workload, pollution and powder quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

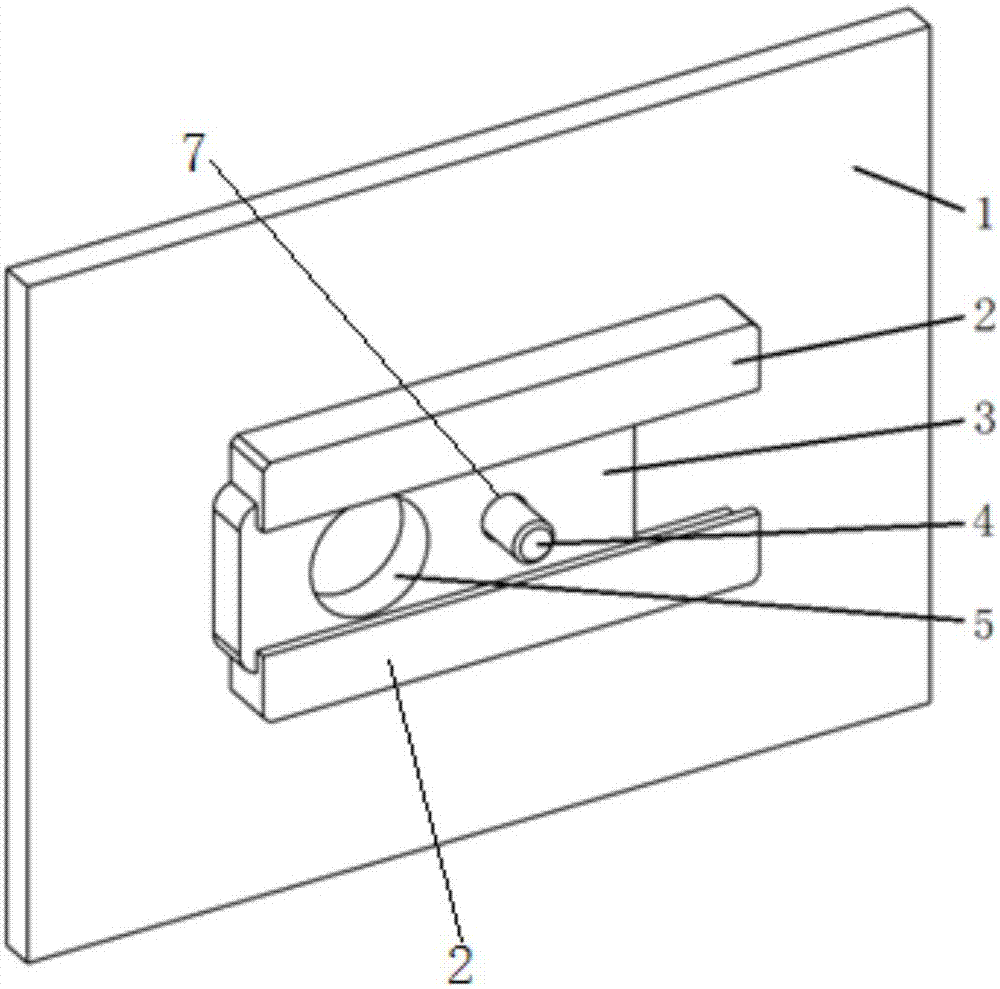

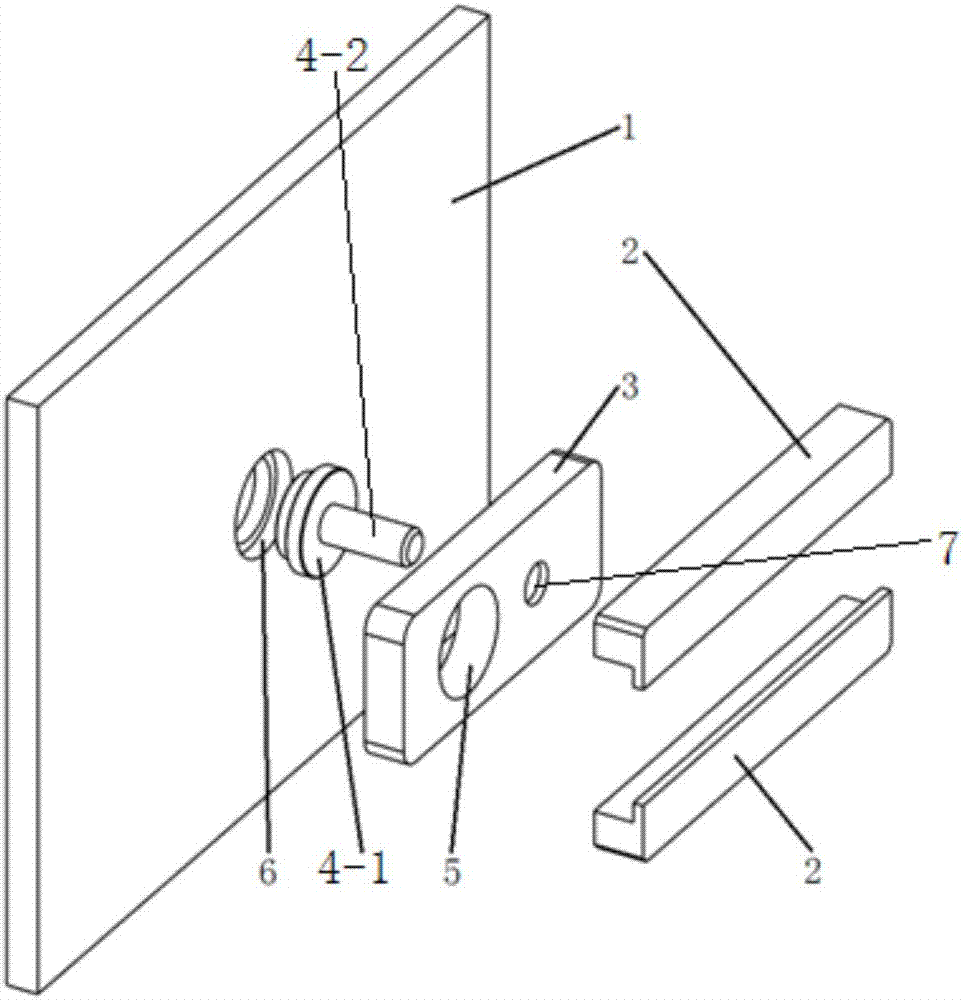

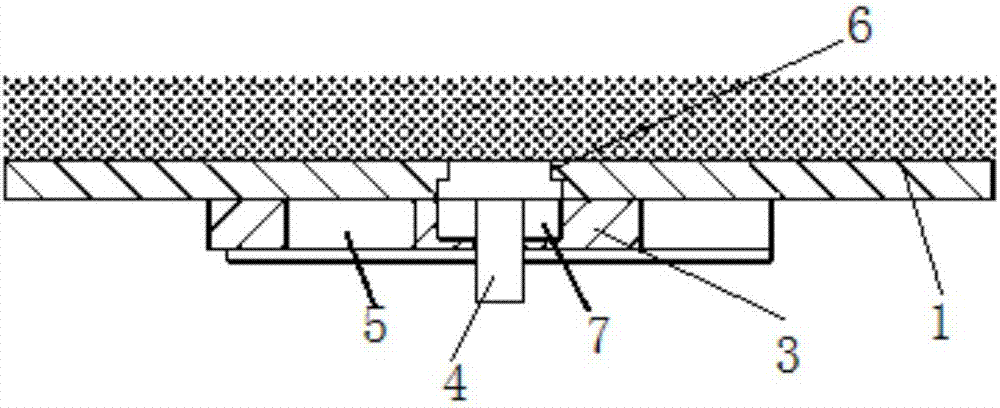

[0021] The present invention is a molding cylinder powder release device for additive manufacturing equipment, such as figure 1 , 2 As shown, the molding cylinder side plate 1 is included, and two slide rails 2 parallel to each other are arranged on one side of the molding cylinder side plate 1, and a vertical powder discharge movable plate 3 is embedded between the two slide rails 2. , the powder discharge movable plate 3 is respectively provided with a powder discharge opening A5 and a stepped hole 7, the center of the powder discharge hole opening A5 and the center of the stepped hole 7 are located on the same horizontal line, and the forming cylinder side plate 1 corresponding to the position of the stepped hole 7 A powder discharge opening B6 is provided, and the plug 4 passes through the stepped hole 7 and is stuck in the powder discha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap