A dust blowing device for a printing press

A technology for printing presses and vacuum cleaners, applied in printing presses, printing, general parts of printing machinery, etc., can solve the problems of easy generation of paper scraps, dust falling on paper, affecting printing quality, etc., to improve quality, paper is clean and tidy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

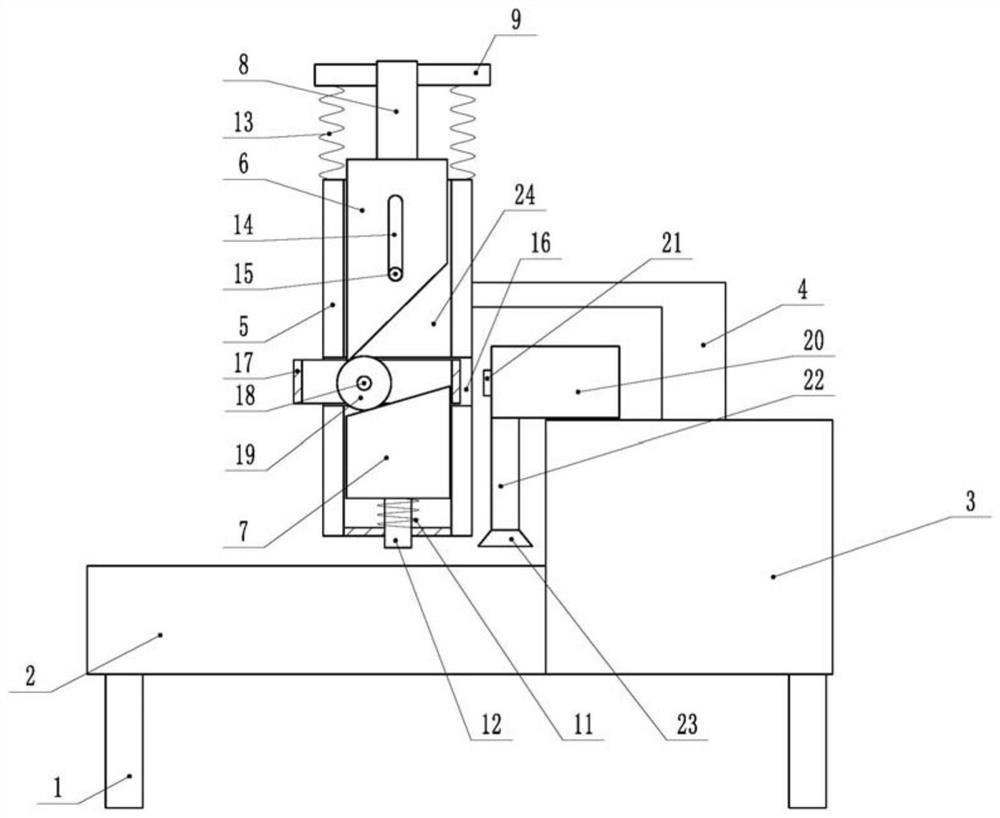

[0024] The example is basically as attached figure 1 Shown: a dust blowing device for a printing machine, comprising a transfer table 2 and a printing machine body 3, and a bracket 1 is welded and fixed to the bottom ends of the transfer table 2 and the printing machine body 3.

[0025] The printing machine body 3 is provided with a feeding port (not shown in the figure), the feeding port is located on the left side of the printing machine body 3 , and the feeding port is used for feeding paper into the printing machine body 3 for printing. The printer body 3 in this embodiment is in the prior art, and the working principle is the same as that of the printer in the prior art, which will not be repeated here.

[0026] The transfer table 2 communicates with the feeding port of the printer body 3 , and the transfer table 2 is used to transfer paper from the feeding port into the printer body 3 . A sliding plate 5 is arranged above the transfer table 2, and the sliding plate 5 is...

Embodiment 2

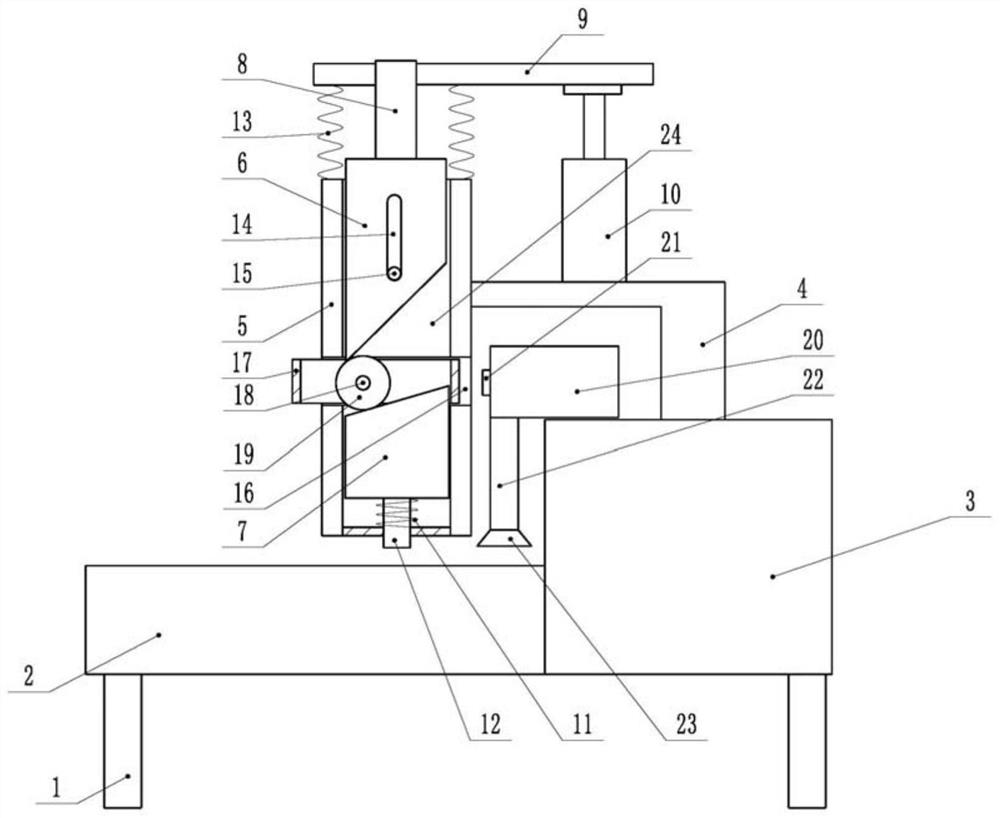

[0036] like figure 2 As shown, a dust blowing device for a printing press is different from the first embodiment in that the top end of the support frame 4 is fixedly connected with an air cylinder 10 by bolts, and the output shaft of the air cylinder 10 and the connecting plate 9 are fixedly connected by bolts.

[0037] In this embodiment, the vertical movement of the connecting plate 9 is automatically controlled by driving the air cylinder 10, thereby controlling the vertical movement of the driving plate 6. This solution does not require manual pressing of the connecting plate 9, which saves labor and labor costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com