Improved sheet running control

A sheet and process technology, applied in the field of sheet travel monitoring, can solve problems such as the consumption of parameters of the machine torsion model, and achieve the effect of reducing time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

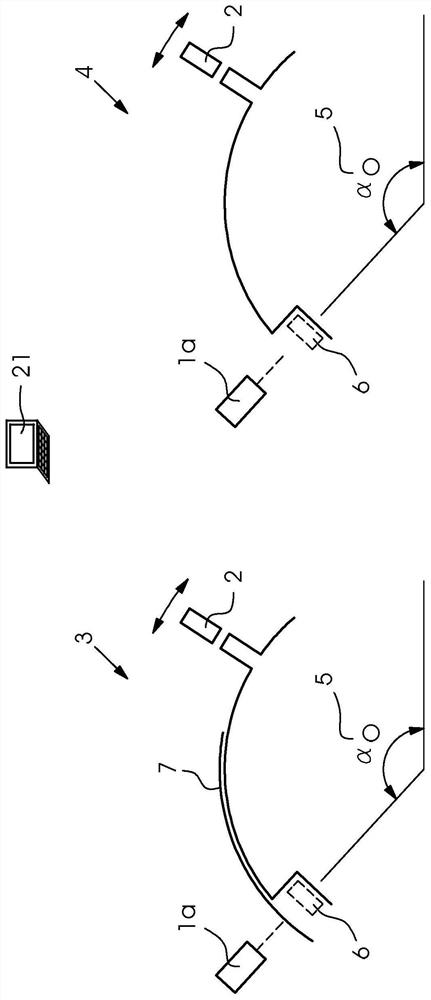

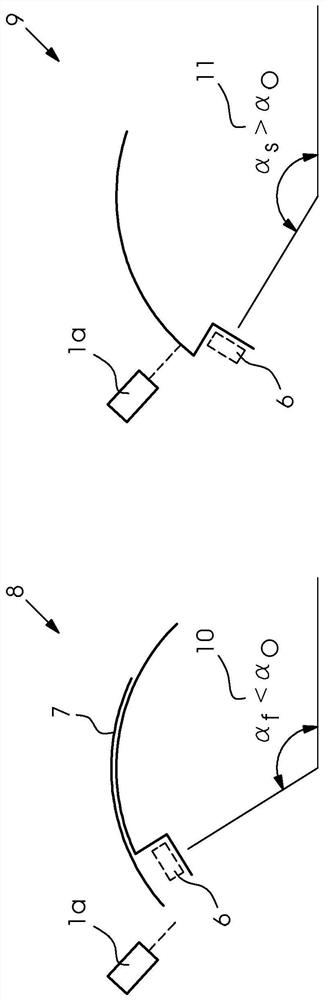

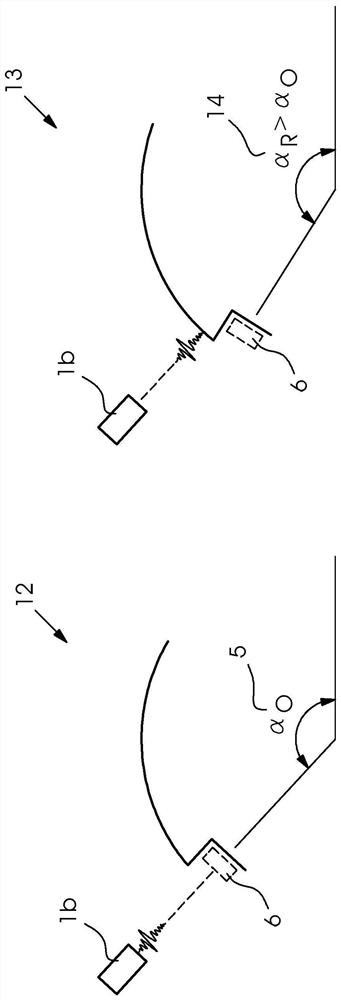

[0029] As in the prior art, a system of activation sensor 2 and sheet travel measuring sensors 1a, 1b is used, which is controlled by a computer. Here, a system of two sensors is used, which consists of the original sheet travel sensors 1a, 1b (hereinafter only referred to as measuring sensors), which detect the excess of the sheet 7 in the gripper, and The sensor 2 and the reflector 6 in the drum, on which an optical or ultrasonic signal is reflected for the measurement, are activated. This system is in figure 1 Shown in , this is more precisely for the measurement 4 in the absence of a sheet, where the corresponding reflected signal thus indicates that no printing sheet 7 is present. on the other hand, figure 1 Measurement 3 is shown in the presence of a sheet, the signal being scattered by the sheet so that this measurement indicates the presence of a printing sheet 7 . However, for the system to function correctly, the activation sensor 2 must be adjusted absolutely cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com