Novel full-automatic pre-overprinting method for photogravure press

A gravure printing machine, fully automatic technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of time-consuming and labor-intensive, high scrap rate, etc., achieve high degree of automation, fast error correction response, and reduce pre-overprinting The effect of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

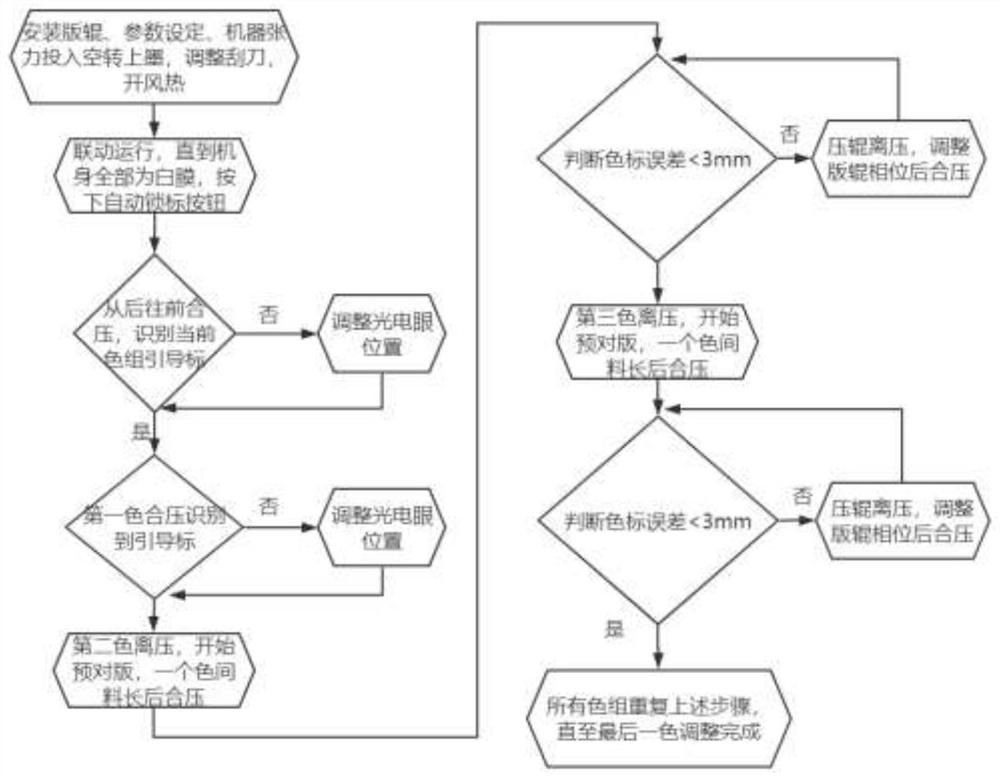

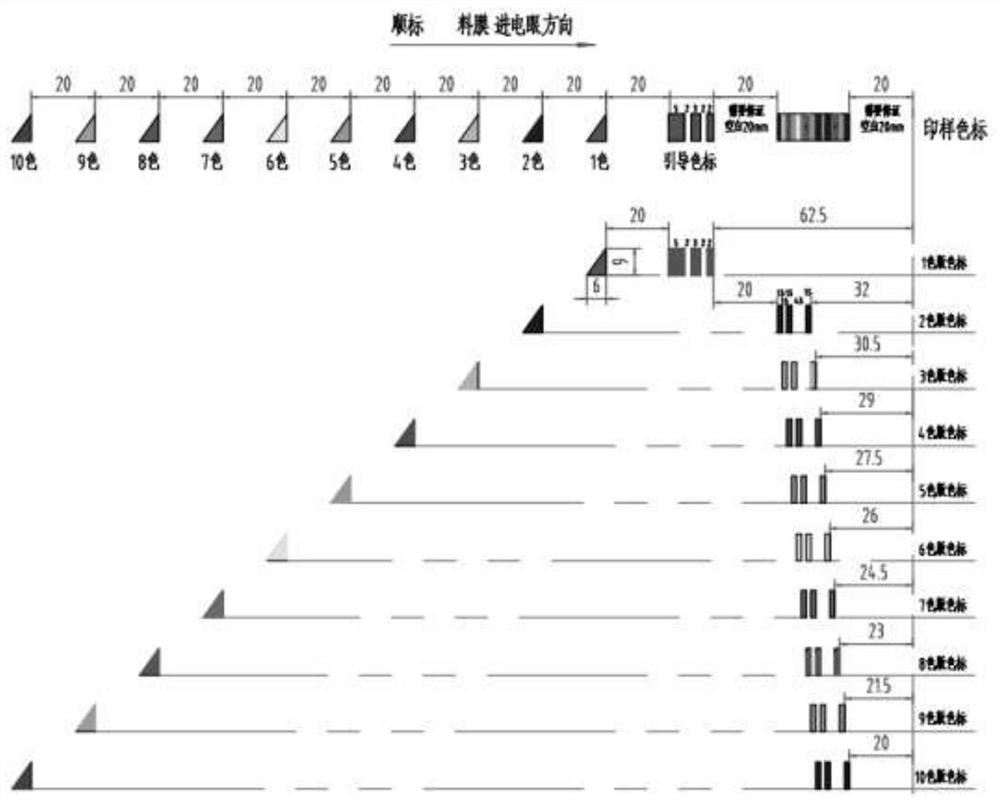

[0048] Taking the automatic pre-registration method of a five-color (five color groups in total) printing machine as an example, the pre-registration process is as follows: Figure 3-8 shown.

[0049] Start-up operation, tension input, ink distribution and other preparations before start-up. After the printing material is fed smoothly, the amount of ink is uniform, and the tension is stable, the printing machine is linked, and the automatic locking button is pressed;

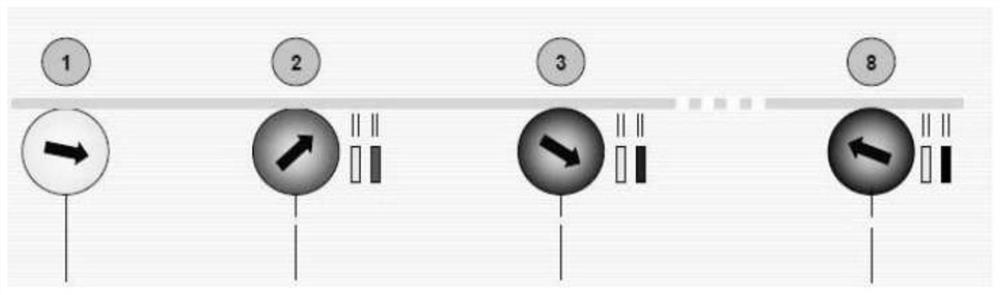

[0050] The printing press roller starts to press automatically from the fifth color. Since each color group is equipped with a color registration sensor, it can recognize and memorize the guide mark and color mark phase printed by the current color group. When the fifth color recognition is completed, the fourth color press roller Automatic pressing, the subsequent color group repeats the above steps until the first color pressure roller is pressed and the standard and phase of the color group are recognized an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com