Printing process for improving brightness uniformity and picture effect of glass diffusion plate

A technology of brightness uniformity and diffuser plate, applied in printing, printing device and other directions, can solve the problem of uneven coating uniformity of glass diffuser plate, solve the uneven thickness of diffuser coating, improve the overall uniformity, and solve the problem of corner retention. white effect

Active Publication Date: 2021-05-28

CHANGZHOU ALMADEN

View PDF16 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the problem of low uniformity of the glass diffuser plate coating in the prior art, the present invention provides a printing process that improves the uniformity of the glass diffuser plate coating, thereby improving the brightness uniformity and picture effect of the glass diffuser plate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

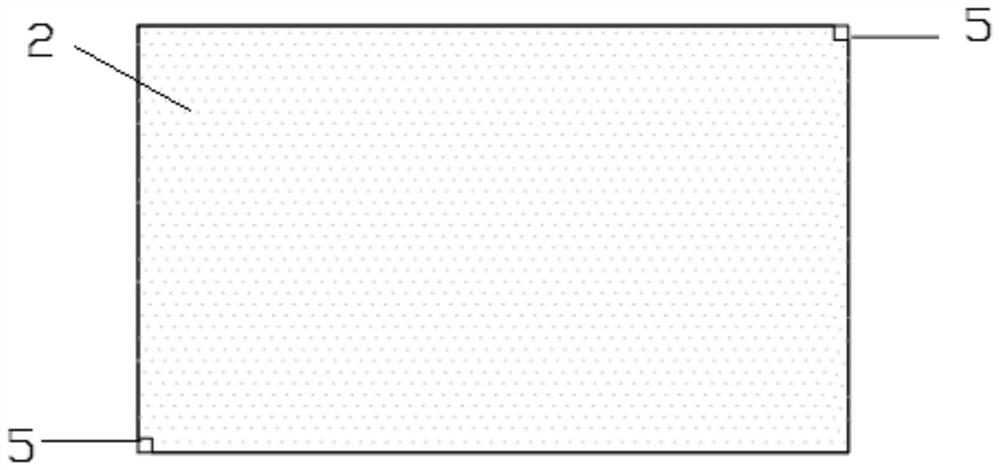

[0041] The four corners of the screen printing plate are used as the extended design of the screen-printed glass diffuser plate. The number of printings is set to 4 times. The first and third times of glass feeding are compared with the second and fourth times by 180° respectively. Obtain a glass diffuser plate with better appearance and optical effect, such as Figure 5 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

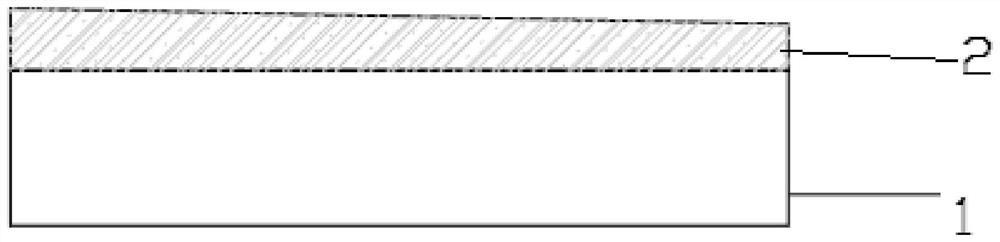

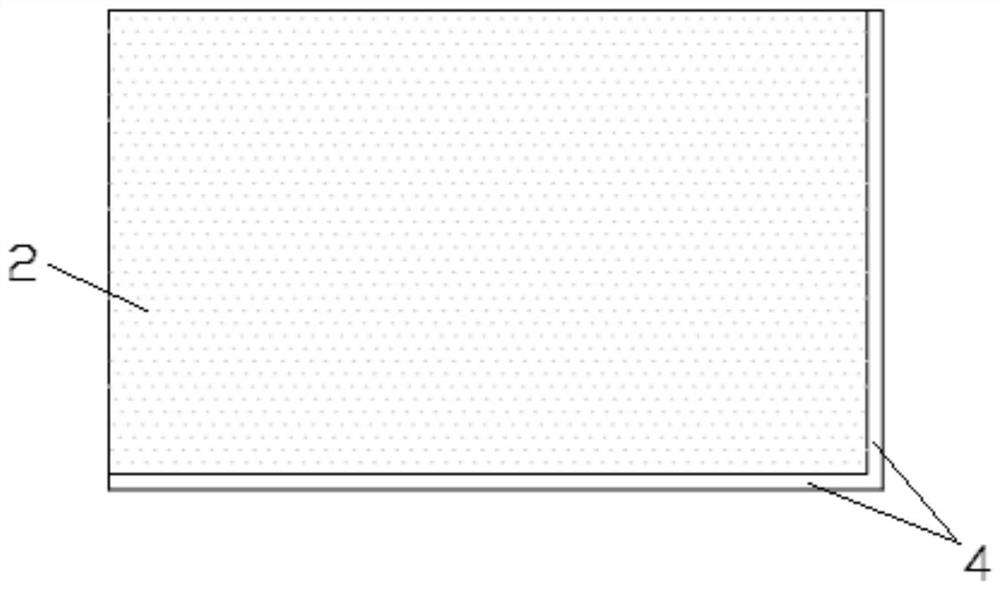

The invention relates to the technical field of glass diffusion plate processing, in particular to a printing process for improving the brightness uniformity and picture effect of a glass diffusion plate. At least two layers of optical films are printed on the same surface of a glass substrate, all the optical films are overlapped to form a diffusion coating, and the printing mode of the optical films adopts a silk-screen printing mode. In the optical film printing process, the placing position of the glass substrate is at least horizontally turned once, the defect that the thickness of the diffusion coating is not uniform can be effectively overcome by changing the feeding mode of the glass substrate, and the overall uniformity of the diffusion coating is improved.

Description

technical field [0001] The invention relates to the technical field of glass diffuser plate processing, in particular to a printing process for improving the brightness uniformity and picture effect of a glass diffuser plate. Background technique [0002] Screen printing is a common process for preparing glass diffuser plates. The production of glass diffuser plates requires high printing uniformity, alignment, and no pinholes. At present, the demand for large-size printing (above 65 inches) is increasing, and for large-size In terms of coating uniformity and alignment accuracy of the screen printing process, the risk of defects such as pinholes increases, and the decrease in uniformity directly affects the optical performance of the diffuser plate. Contents of the invention [0003] In order to solve the problem of low uniformity of the coating of the glass diffusion plate in the prior art, the present invention provides a printing process for improving the uniformity of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B41M1/34B41M1/12

CPCB41M1/34B41M1/12

Inventor 陈雪莲叶茂村林俊良林金汉林金锡

Owner CHANGZHOU ALMADEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com