Packaging equipment for film roll

A technology for packaging equipment and film rolls, which is applied in the field of film roll packaging equipment, and can solve problems such as vacancy in the package area, displacement and rolling of items, overlapping coverage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

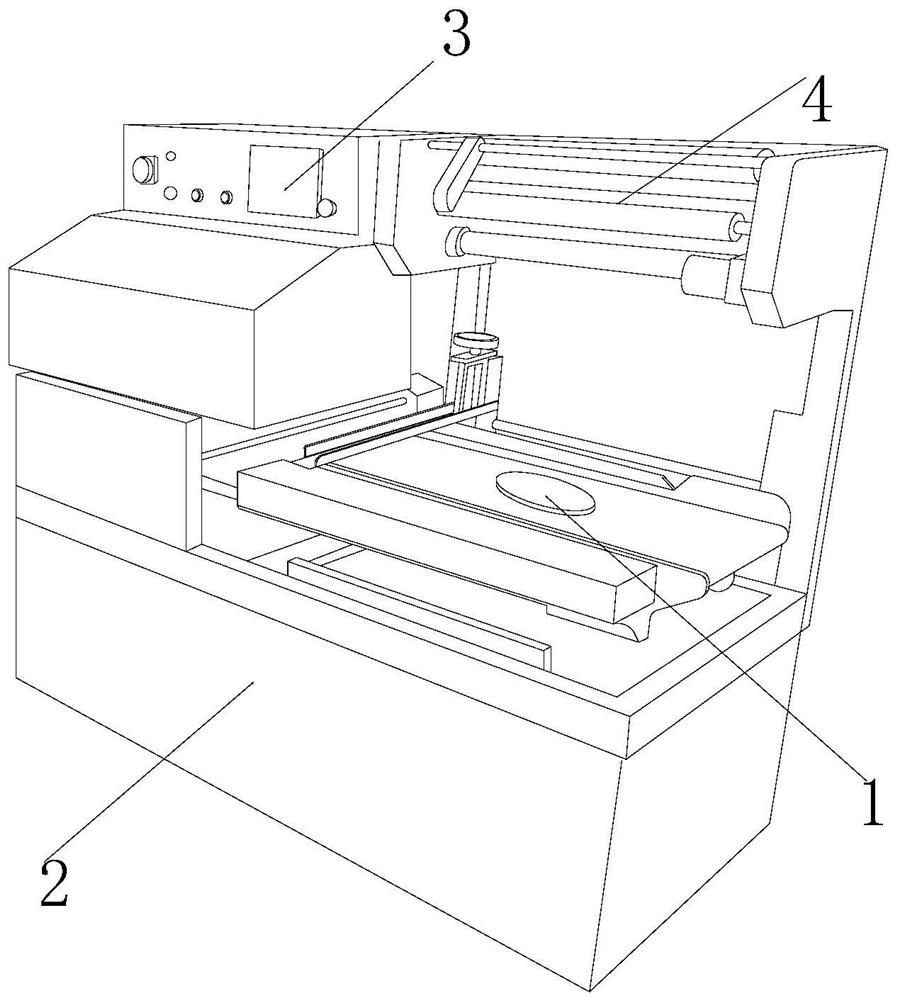

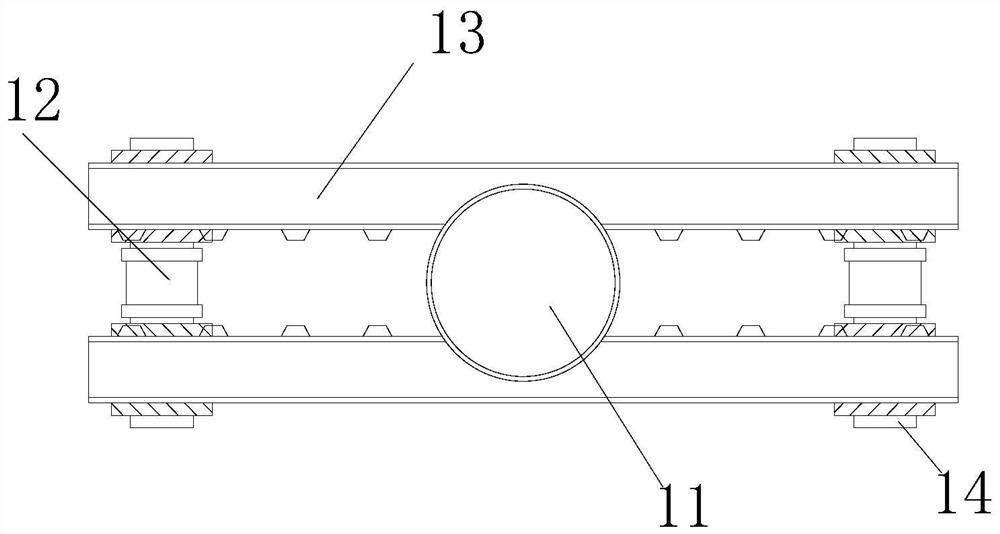

[0025] as attached figure 1 to attach Figure 5 Shown:

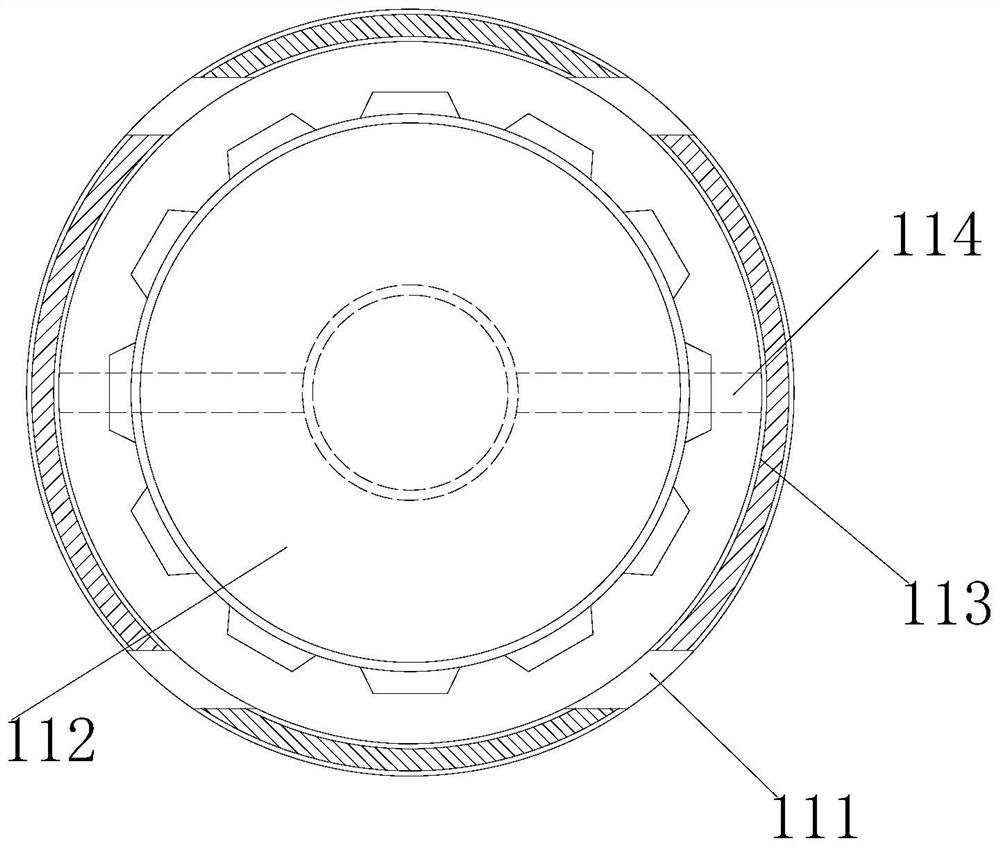

[0026] The present invention provides a packaging device for film rolls, the structure of which includes a turntable 1, a machine body 2, a control panel 3, and a winder 4. The turntable 1 is embedded directly below the winder 4, and the body 2 A control panel 3 is fixedly installed on the left side of the upper end, the control panel 3 is located on the left side of the winder 4, and the winder 4 is fixedly installed directly above the body 2; the turntable 1 includes a movable disc 11 , a two-way wheel 12, a conveyor belt 13, and a runner 14, the movable plate 11 is movably engaged with the conveyor belt 13, the upper and lower ends of the two-way wheel 12 are inlaid and engaged with the runner 14, and the conveyor belt 13 is symmetrically installed on the movable The upper and lower ends of the disc 11 and the outer end surface of the runner 14 are attached to wrap the conveyor belt 13 .

[0027] Wherein, the movab...

Embodiment 2

[0033] as attached Figure 6 to attach Figure 7 Shown:

[0034] Wherein, the adsorption mechanism 233 includes a fitting sheet 331, an air permeation hole 332, a hollow groove 333, and a rubber sheet 334. The lamination sheet 331 is inlaid directly above the air permeation hole 332, and the air permeation hole 332 is inlaid and mounted On the inner lower end surface of the adsorption mechanism 233, the hollow groove 333 is inlaid on the inner end surface of the fixing strip 335, the rubber sheet 334 is attached and connected to the fitting sheet 331, and the fixing strip 335 is symmetrically installed on the rubber sheet 334 The left and right ends of the hollow groove 333 are hollowed out in a triangular shape, and the hollow groove 333 can be deformed by the downward extrusion of the rubber sheet 334, and at the same time, the air in the adsorption mechanism 233 can be discharged outward.

[0035]Wherein, the air permeation hole 332 includes a second rubber sheet 321, a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com